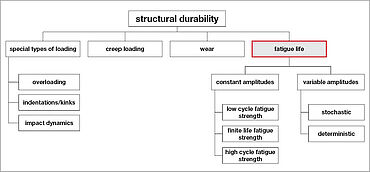

Fatigue Life

Fatigue life is a term used in fatigue testing and refers to the deformation and failure behavior of materials under cyclic loading.

A fatigue life test with constant amplitudes is referred to as S-N test, where the tolerable stress amplitude is determined using the corresponding number of cycles.

Cycle characteristic values Types of loading S-N curve Testing machines

Types of Loading for the Determination of Fatigue Life

In fatigue life tests the material or component is subjected to load changes. This reduces the permissible stress in a material: A break can occur before the tensile strength is reached; in part even without having exceeded the linear-elastic range.

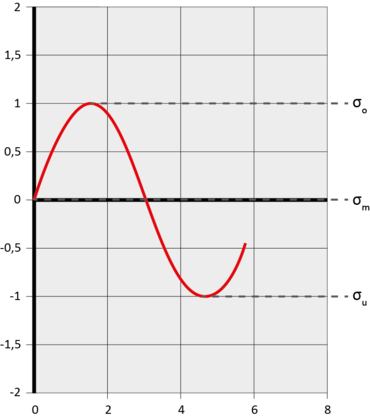

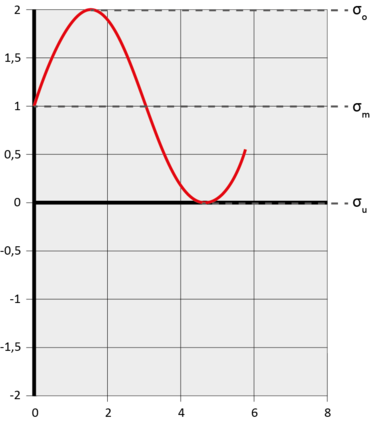

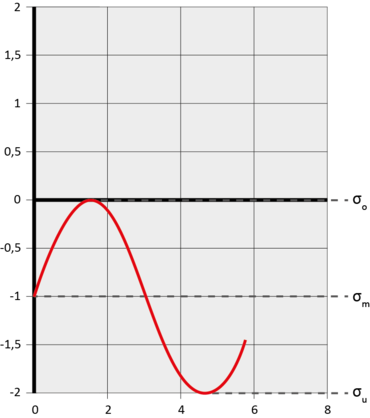

In general, load changes are interpreted as cycles, which can be carried out under different load ratios.

Calculation of load ratio: R=σu / σo

S-N curve (Woehler curve)

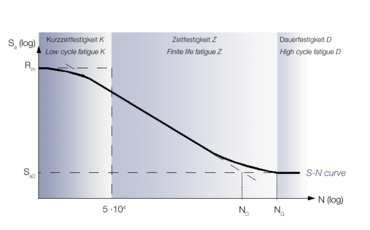

The S-N curve is derived from high cycle fatigue tests (also S-N tests) to DIN 50100, and is divided into the regions of low cycle fatigue K, finite life fatigue Z and high cycle fatigue D.

From the S-N diagram you can read the maximum number of load changes for a certain load amplitude. It is dependent on the material properties, the force and the load application type (pulsating compression load, pulsating tensile load or alternating load).

Low Cycle Fatigue

Low cycle fatigue K is the range below approx. 104 to 105 load cycles. Low cycle fatigue strength is determined with the low cycle fatigue (LCF) test.

Finite Life Fatigue

High cycle fatigue Z is the range between 104 and 2·106 cycles (dependent on the material).

Finite life fatigue strength is determined with the high cycle fatigue (HCF) test. After the test, the result is the number of load cycles at one load amplitude.

High Cycle Fatigue

High cycle fatigue D denotes the stress limit that a material can endure during cyclic loading without significant signs of fatigue or failure.

Materials that, during a high cycle fatigue test , endure more than 1,000,000 cycles without fracture are considered to be fatigue resistant.