Material

- Metals

- Wood

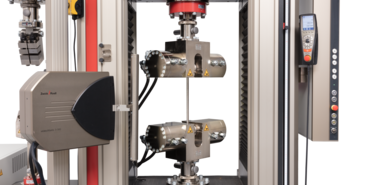

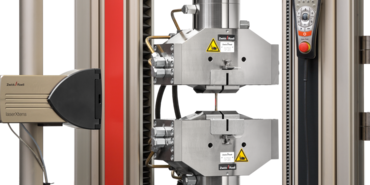

Test load

- 50 kN - 250 kN

Specimen shape

- Flat specimens

- Round specimens

- Short clamping lengths

Type of test

- Tensile

- Compression

- Alternating load

Properties according to force range

| Item No. | 3136461 | |

| Type | 8494 | |

| Test load Fmax | 50 | kN |

| Operating principle/identification | Double-sided closing | |

| Gripping force, max. at 300 bar | 100 | kN |

| Operating pressure | 12 ... 300 | bar |

| Dimensions | ||

| Height | 205 | mm |

| Width | 386 | mm |

| Depth | 132 | mm |

| Gripping travel | 35 | mm |

| Opening width with jaws | See table of jaws (specimen thickness) | |

| Gripping of the specimen | The specimen must be gripped with at least 2/3 of the jaw height. | |

| Weight per specimen grip, approx. | 37 | kg |

| Connection | Ø 36/602 | mm |

| Ambient temperature | +10 ... +35 | °C |

| Scope of delivery | 2 | pieces |

- Recommended and approved for strain rate control to standards DIN EN ISO6892-1:2009 and ASTM E8-09.

- These specimen grips can be offered with a 36 mm or 60 mm connection (selection made using parts list alternatives).

| Item No. | 0325621 | |

| Type | 8495 | |

| Operating principle/identification | Double actuator | |

| Operating principle | Short clamping | |

| Test load Fmax | 50 | kN |

| Gripping force, max. at 300 bar | 110 | kN |

| Operating pressure, max. | 300 | bar |

| Dimensions | ||

| Height | 316 | mm |

| Width | 413 | mm |

| Depth | 278 | mm |

| Opening width with jaws | 34 | mm |

| Permissible surface pressure on jaw, max. | 1000 | N/mm2 |

| Grip-to-grip separation, approx. | 6 | mm |

| Weight per specimen grip, approx. | 69 | kg |

| Connection | Ø 36 | mm |

| Ambient temperature | +10 ... +35 | °C |

| Scope of delivery | 2 | piece(s) |

- Recommended and approved for strain rate control compliant to standards DIN EN ISO 6892-1:2009 and ASTM E8–09.

| Item No. | 0325631 | |

| Type | 8495 | |

| Operating principle/identification | Double actuator | |

| Operating principle | Short clamping | |

| Test load Fmax | 70 | kN |

| Gripping force, max. at 300 bar | 110 | kN |

| Operating pressure, max. | 300 | bar |

| Dimensions | ||

| Height | 349 | mm |

| Width | 413 | mm |

| Depth | 278 | mm |

| Opening width with jaws | 34 | mm |

| Permissible surface pressure on jaw, max. | 1000 | N/mm2 |

| Grip-to-grip separation, approx. | 6 | mm |

| Weight per specimen grip, approx. | 69 | kg |

| Connection | Ø 60 | mm |

| Ambient temperature | +10 ... +35 | °C |

| Scope of delivery | 2 | piece(s) |

- Recommended and approved for strain rate control compliant to standards DIN EN ISO 6892-1:2009 and ASTM E8–09.

| Item No. | 3137601 | |

| Type | 8592 | |

| Operating principle/identification | Double-actuator | |

| Test load Fmax | 100 | kN |

| Gripping force, max. at 300 bar | 250 | kN |

| Gripping force, max. at 480 bar | - | |

| Dimensions | ||

| Height | 303 | mm |

| Width | 479 | mm |

| Depth | 170 | mm |

| Width with screw unit, open completely | 461 | mm |

| Gripping travel | 70 | mm |

| Gripping of the specimen | The specimen must be gripped with at least 2/3 of the jaw height | |

| Weight per specimen grip, approx. | 70 | kg |

| Connection | Ø 60 | mm |

| Ambient temperature | +10 ... +35 | °C |

| Scope of delivery | 2 | pieces |

- Recommended and approved for strain rate control to standards DIN EN ISO6892-1:2009 and ASTM E8-09.

| Item No. | 04649612 | |

| Type | 8589 | |

| Operating principle/identification | Short clamping | |

| Test load Fmax | 150 | kN |

| Operating principle | Two-sided closing | |

| Gripping force, max. | 275 | kN |

| Operating pressure, max. | 300 | bar |

| Grip-to-grip separation, min. | 15 | mm |

| Dimensions | ||

| Height | 490 | mm |

| Width | 570 | mm |

| Depth | 445 | mm |

| Opening width with jaws | 59 | mm |

| Weight per specimen grip, approx. | 215 | kg |

| Connection | Ø 60 | mm |

| Ambient temperature | +10 ... +35 | °C |

| Scope of delivery | 2 | pieces |

- Not possible in connection with Z100 THW, Z150 TL and Z250 RED

- Recommended and approved for strain rate control to standards DIN EN ISO6892-1:2009 and ASTM E8-09.

| Item No. | 3137821 | |

| Type | 8594 | |

| Operating principle/identification | Double actuator | |

| Test load Fmax | 250 | kN |

| Gripping force, max. at 480 bar | 410 | kN |

| Gripping force, max. at 300 bar | - | |

| Opening width with jaws | 59 | mm |

| Dimensions | ||

| Height | 303 | mm |

| Width | 479 | mm |

| Depth | 170 | mm |

| Width with screw unit, open completely | - | mm |

| Gripping travel | 35 | mm |

| Gripping of the specimen | The specimen must be gripped with at least 2/3 of the jaw height | |

| Connection | Ø 60 | mm |

| Ambient temperature | +10 ... +35 | °C |

| Weight per specimen grip, approx. | 70 | kg |

| Scope of delivery | 2 | pieces |

- Recommended and approved for strain rate control to standards DIN EN ISO6892-1:2009 and ASTM E8-09.

| Item No. | 04687312 | |

| Type | 8589 | |

| Operating principle/identification | Short clamping | |

| Test load Fmax | 250 | kN |

| Operating principle | Double actuator | |

| Gripping force, max. | 420 | kN |

| Operating pressure, max. | 400 | bar |

| Grip-to-grip separation, min. | 15 | mm |

| Dimensions | ||

| Height | 490 | mm |

| Width | 570 | mm |

| Depth | 445 | mm |

| Opening width with jaws | 59 | mm |

| Weight per specimen grip, approx. | 215 | kg |

| Connection | Ø 60 | mm |

| Ambient temperature | +10 ... +35 | °C |

| Scope of delivery | 2 | piece(s) |

- Not possible in connection with Z100 THW, Z150 TL and Z250 RED

- Recommended and approved for strain rate control compliant to standards DIN EN ISO 6892-1:2009 and ASTM E8–09.

| Type | 330 | kN |

| Item No. | 1014893 | |

| Maximum tensile force, Fmax | 330 | kN |

| Maximum gripping force | 588 | kN |

| Flat specimens | ||

| Gripping area | 0 ... 80 | mm |

| Thickness, max. | 80 | mm |

| Width, max. | 95 | mm |

| Round specimens | ||

| Gripping area | 5.5 ... 80 | mm |

| System pressure, max. | 480 | bar |

| the required | ||

| Height (H) | 280 | mm |

| Width (W) | 550 | mm |

| Depth (D) | 220 | mm |

| Weight (each) | 205 | kg |

| Type | 400 | kN |

| Item No. | 1014894 | |

| Maximum tensile force, Fmax | 400 | kN |

| Maximum gripping force | 588 | kN |

| Flat specimens | ||

| Gripping area | 0 ... 80 | mm |

| Thickness, max. | 80 | mm |

| Width, max. | 95 | mm |

| Round specimens | ||

| Gripping area | 5.5 ... 80 | mm |

| System pressure, max. | 480 | bar |

| the required | ||

| Height (H) | 280 | mm |

| Width (W) | 550 | mm |

| Depth (D) | 220 | mm |

| Weight (each) | 205 | kg |

| Type | 600 | kN |

| Item No. | 084473 | |

| Maximum tensile force, Fmax | 600 | kN |

| Maximum gripping force | 965 | kN |

| Flat specimens | ||

| Gripping area | 0 ... 100 | mm |

| Thickness, max. | 100 | mm |

| Width, max. | 128 | mm |

| Round specimens | ||

| Gripping area | 5.5 ... 100 | mm |

| System pressure, max. | 480 | bar |

| the required | ||

| Height (H) | 350 | mm |

| Width (W) | 630 | mm |

| Depth (D) | 250 | mm |

| Weight (each) | 320 | kg |

| Type | 1200 | kN |

| Item No. | 1015113 | |

| Maximum tensile force, Fmax | 1200 | kN |

| Maximum gripping force | 1600 | kN |

| Flat specimens | ||

| Gripping area | 0 ... 100 | mm |

| Thickness, max. | 100 | mm |

| Width, max. | 162 | mm |

| Round specimens | ||

| Gripping area | 5.5 ... 100 | mm |

| System pressure, max. | 480 | bar |

| the required | ||

| Height (H) | 459 | mm |

| Width (W) | 790 | mm |

| Depth (D) | 320 | mm |

| Weight (each) | 700 | kg |

| Type | 1600 | kN |

| Item No. | 628448 | |

| Maximum tensile force (Fmax) | 1600 | kN |

| Maximum gripping force | 2750 | kN |

| Flat specimens | ||

| Clamping range | 0 to 80 | mm |

| Max. thickness | 80 | mm |

| Max. width | 210 | mm |

| Round specimens | ||

| Clamping range | 5.5 to 80 | mm |

| Max. system pressure | 480 | bar |

| Dimensions | ||

| Height (H) | 603 | mm |

| Width (W) | 940 | mm |

| Depth (D) | 390 | mm |

| Weight (each) | 1305 | kg |

| Type | 2000 | kN |

| Item No. | 084466 | |

| Maximum tensile force (Fmax) | 2000 | kN |

| Maximum gripping force | 2750 | kN |

| Flat specimens | ||

| Clamping range | 0 ... 100 | mm |

| Max. thickness | 100 | mm |

| Max. width | 205 | mm |

| Round specimens | ||

| Clamping range | 5.5 ... 100 | mm |

| Max. system pressure | 480 | bar |

| Dimensions | ||

| Height (H) | 603 | mm |

| Width (W) | 940 | mm |

| Depth (D) | 390 | mm |

| Weight (each) | 1325 | kg |

| Type | 2500 | kN |

| Item No. | 611432 | |

| Maximum tensile force (Fmax) | 2500 | kN |

| Maximum gripping force | 3850 | kN |

| Flat specimens | ||

| Clamping range | 0 ... 100 | mm |

| Max. thickness | 100 | mm |

| Max. width | 210 | mm |

| Round specimens | ||

| Clamping range | 5.5 ... 100 | mm |

| Max. system pressure | 480 | bar |

| Dimensions | ||

| Height (H) | 650 | mm |

| Width (W) | 1090 | mm |

| Depth (D) | 430 | mm |

| Weight (each) | 1765 | kg |

Downloads

Name

Type

Size

Download

- Product information: Hydraulic grips, Fmax 50 kN PDF 146 KB

- Product information: Hydraulic grips, Fmax 100 kN / 250 kN PDF 691 KB

- Product information: Hydraulic grips for short clamping lengths, Fmax 50 kN / 70 kN PDF 369 KB

- Product information: Hydraulic grips for short clamping lengths, Fmax 150 kN / 250 kN PDF 330 KB

- Product information: Hydraulic grips up to 2500 kN PDF 280 KB