Ensayo de tracción

El ensayo de tracción es un método de ensayo mecánico de materiales para determinar los valores característicos de los materiales. Según el tipo de material, se emplea como método estándar de acuerdo con la respectiva norma para determinar el límite elástico, la resistencia a la tracción, el alargamiento de rotura, entre otros valores característicos.

El ensayo de tracción consiste en aplicar un esfuerzo axial a una probeta hasta su rotura. La velocidad de deformación aplicada para no distorsionar el resultado debe ser baja. Durante el ensayo de tracción, se mide la fuerza y la extensión de la probeta.

En el ámbito de los ensayos mecánicos, los ensayos de tracción son los más habituales, junto a la medición de la dureza. Sirven para determinar las propiedades de resistencia y deformación bajo solicitación de tracción.

Uso Distinción por solicitación Distinción por material máquina de ensayos Otros ensayos

Ensayo de tracción - objeto y significado

Los ensayos de tracción se llevan a cabo

- en probetas estrechas mecanizadas para determinar el comportamiento del material bajo solicitación uniaxial uniformemente distribuida en la sección de la probeta,

- en probetas con entalla para la simulación de estados de tensión multiaxial –ensayo de tracción con entalladura–, o también

- en productos, como cables y alambres, hilos, películas y láminas, cuerdas, elementos de moldeo, componentes o grupos de componentes, a continuación –en adelante, denominados probetas cortas.

durchgeführt.

En el ensayo de tracción se analiza el comportamiento de materiales

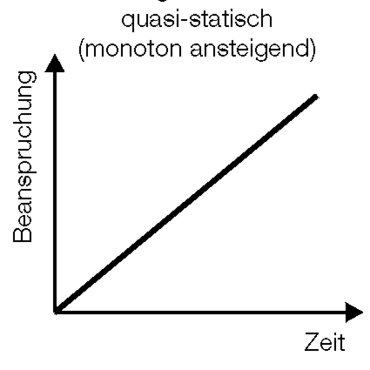

- a una carga continua en aumento (suave) ̶̶–ensayo «clásico» cuasiestático

- a una carga constante en reposo (estática) –ensayo de fluencia

- a una carga alternante para determinar la curva cíclica de tensión-deformación –

- a temperatura ambiente (entre 10 y 35 °C)

- a altas temperaturas (hasta muy por encima de 1.000 °C)

- a bajas temperaturas (hasta – 269 °C)

- a velocidades de ensayo muy reducidas ̶̶–ensayos de fluencia en tracción– o también

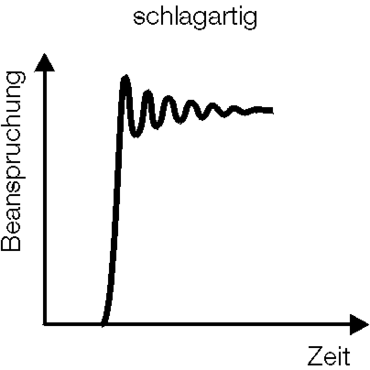

- a altas velocidades de ensayo –ensayos de tracción y de desgarro a alta velocidad

untersucht.

Los valores característicos determinados en el ensayo de tracción

- constituyen la base para calcular y dimensionar componentes y construcciones bajo carga estática,

- son necesarios para la caracterización del comportamiento durante el procesamiento de los materiales,

- sirven en el proceso de control de calidad para evaluar la uniformidad de la producción y

- se emplean en la selección de materiales para comparar materiales y sus estados.

Diferenciación del ensayo de tracción según la progresión temporal de la carga

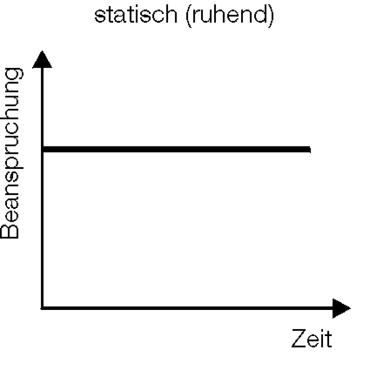

Generalmente, se distingue entre ensayos de tracción bajo solicitación estática, cuasiestática, cíclica y de impacto.

Generalmente, una carga se considera estática cuando se somete el material a una carga constante en reposo. En el ensayo de tracción «clásico» se aplica una carga continua en aumento sin impacto (cuasiestática). El límite superior para distinguir el método de ensayo cuasiestático se encuentra a una velocidad de deformación de aprox. 10-1s-1, es decir, el máximo aumento, p. ej. de la deformación, no puede superar un 0,1 % por segundo.

Diferenciación del ensayo de tracción según el material a ensayar

El ensayo de tracción es un método estándar normalizado del ensayo de materiales, con diferentes requerimientos en el procedimiento según el material/sector.

Nuestros expertos de cada sector, conocen bien dichos requerimientos y le ayudarán a configurar el sistema de ensayos que más se adapte a sus necesidades.

En la siguiente lista, encontrará ejemplos de descripciones de ensayos de tracción en diferentes sectores.