Hole expansion test to KWI

KWI test

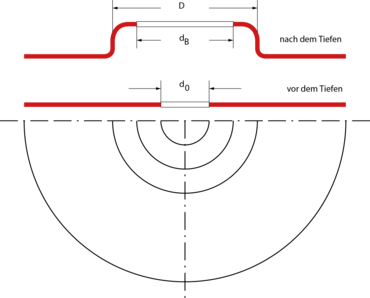

The hole expansion test to KWI is a method for the determination of sheet metal forming properties and is used to understand the change in shape of a sheet metal edge.

For testing of thin sheets, specimens with a hole are clamped on the outer edges and deep drawn. The part of the specimen in front of the face of the drawing die is strained in a tangential direction until onset of cracking.

The percentage of hole expansion of the hole at crack onset is an indication of the ductility of a material under load, which is similar to that which occurs in a range of deep draw operations in cooperation with radial and tangential stresses.