Automated Tensile Tests on Steel in China’s Largest Steel Mill

Baoshan Iron & Steel Co. Ltd. is a Chinese steel producer based in Shanghai and subsidiary of the state-owned China Boawu Steel Group. It is the largest steel manufacturer in China and the second largest in the world.

As a result of the boom in the steel industry, the number of specimens in the testing laboratories increased. In order to process the required tests with the existing personnel and in a timely manner, the use of automated processes has increased. With the elimination of operator influences, there is also an improvement in the quality of the tests—a basic requirement to achieve increasing product quality.

Test sequence: automated tensile tests on steel

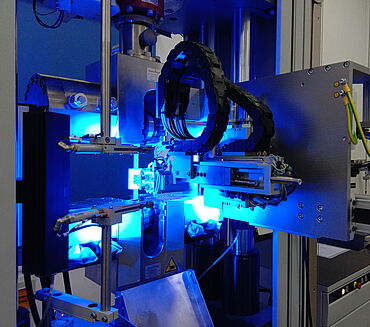

The operator places the steel specimens with QR code in the magazine. After the automatic sequence is started, the robotic testing system roboTest L takes the first specimen and identifies it by reading the QR code.

The next step is fully automated measurement of the specimen geometry with a cross-section measuring device. By determining the cross-section, angular and parallax errors can be avoided. For example, an inaccuracy from a manual change in width measurement (i.e., with a caliper) can affect the tensile testing machine’s r-value determination.

The last step is the performance of the tensile test according to international standards such as ISO 6892. The steel specimen is centrally positioned in the double-sided hydraulic grips and accurately aligned. This eliminates subjective operator influences on the test. During the tensile test, a laserXtens extensometer measures the elongation on both sides of the steel specimen. The laserXtens also measures the change in width for calculation of the r-value. In this case, the non-contact and wear-free extensometer is used especially for high-strength material with small elongations.

While the testing machine is performing the tensile test, the robotic testing system measures the cross-section of the next steel specimen, increasing the throughput.

After the tensile test, the specimen remains are sorted into a good/bad container. The results are automatically transferred to a host system.