Modernisation des machines d’essai

Préparez votre machine d’essai pour l’avenir! Grâce à nos modernisations, nous mettons votre machine d'essais aux standards les plus actuels. Profitez de nombreux avantages et prolongez la durée de vie de votre machine pendant de nombreuses années supplémentaires.

Nous proposons également nos modernisations pour plus de 50 machines d’essais d’autres fabricants. Avec plusieurs milliers de modernisations réalisées, vous pouvez compter sur notre compétence et sur notre qualité.

| Avantages d’une modernisation | ZwickRoell Modernisation | Fabricants tiers Modernisation |

|

|

Raisons de moderniser Témoignages clients Téléchargements FAQ

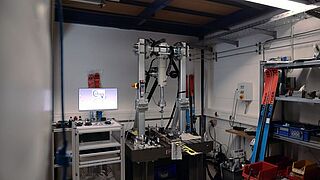

Modernisation d’une machine d’essai au siège à Ulm

Dans cette vidéo, nous vous montrons étape par étape le processus de modernisation réalisé sur notre machine d’essai de sol AllroundLine au siège de ZwickRoell à Ulm. Le résultat : une machine d’essai universelle équipée de la toute dernière électronique de pilotage et d’acquisition, de la dernière génération de logiciels ainsi que d’un nouvel entraînement, et de ce fait comparable à une machine neuve.

Que comprend la modernisation d’une machine d’essai ?

Lors d’une modernisation, le bâti de charge existant bénéficie d’une préparation et l’électronique, l’entraînement et le logiciel d'essai reçoivent une mise à niveau complète. Une machine d'essai modernisée est totalement équivalente à une machine neuve et vous offre donc les mêmes possibilités et avantages. Vous réalisez, de plus, des économies par rapport à l'achat d'une machine d’essai neuve et préservez l'environnement.

Raisons de moderniser votre machine d’essai

- Technologie d'essai obsolète et/ou logiciel d'essai obsolète

- Modification des demandes d’essais ou applications ou intégration de nouveaux produits ou accessoires

- Résiliation du support du système d'exploitation ou de l'électronique de mesure, de pilotage et de régulation

- Temps d’immobilisation prolongés lors du remplacement de composants électroniques obsolètes

- Augmentation de la sécurité de fonctionnement

- Utilisation de nouveaux outils numériques tels que testXpert Analytics ou Remote Support

Modernisation de machines d’essais statiques

Nous modernisons vos machines d’essais statiques, qu'il s'agisse de machines électrostatiques ou hydrauliques-statiques et ce quelle que soit leur année de construction. Pour ce faire, nous remplaçons les éléments suivants et les mettons aux standards les plus actuels:

- Électronique de pilotage et acquisition testControl II

- Entraînement AC

- Technologie capteur

- Accessoires

- Logiciel d'essais testXpert

Modernisation de machines d’essais dynamiques

Que vous possédiez des machines d'essais servohydrauliques, électromécaniques ou vibrophores, nous vous proposons également à vos machines d'essai dynamiques grâce à nos paquets de modernisation modulaires. Les paquets modernisation contiennent les éléments suivants:

- Électronique de mesure, de pilotage et de régulation testControl II, puissante

- Logiciel d'essais testXpert

- Kits de modernisation spéciaux pour adaptation de capteurs existants (capteurs de force, extensomètres, etc.)

- Valves proportionnelles ou servovalve, tubes hydrauliques ou accumulateurs de pression

- Nouveau groupe hydraulique ou adaptation de composants hydrauliques existants

Clients satisfaits des modernisations dynamiques

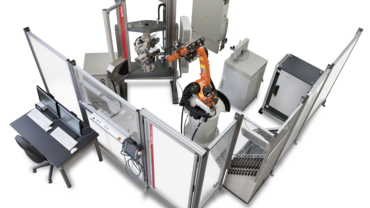

Modernisation de systèmes d'essais automatisés

Outre les machines d'essais statiques et dynamiques, les systèmes d'essais automatisés peuvent aussi être modernisés. La modernisation comprend:

- La mise à jour du logiciel d'automatisation autoEdition ou de testXpert de même que de la liaison aux bases de données spécifiques clients

- Intégration d’un nouvel ordinateur de pilotage incluant la mise à jour de Windows

- Remplacement du robot

- Électronique de pilotage et acquisition testControl II

- Remplacement de composants de commande mécaniques tels que l'îlot de vannes ou le coupleur de bus et de composants soumis à des contraintes mécaniques tels que les pinces à éprouvettes

Modernisation de fabricants tiers

Nous modernisons également les machines d’essais d’autres fabricants pour les adapter à la technologie d’essais ZwickRoell. Nous utilisons des composants et un niveau de qualité identiques à celui de nos propres machines d'essais. Nous avons déjà modernisé les machines de plus de 50 fabricants différents. Parmi celles-ci:

- Instron®

- Hegewald & Peschke

- Shimadzu

- MTS

- Tinius Olsen

- Schenck

- Rumul

- Walter+bai

- et bien d’autres encore

Modernisation servohydraulique de la machine d'essai MTS par ZwickRoell

Enercon fait partie des fournisseurs leaders d'installations éoliennes dans le monde. Pour consolider cette position, Enercon mise sur ZwickRoell et la modernisation de trois machines d'essais servohydrauliques de la société MTS.

Disponibilité des pièces de rechange prolongée de 10 années supplémentaires

En modernisant votre machine d'essai, nous vous promettons au moins 10 ans de pièces de rechange. Nous dépassons par conséquent nettement les exigences habituelles de l'industrie et veillons à ce que vous puissiez faire confiance à votre machine sur le long terme. Profitez ainsi des garanties d’une machine d'essai neuve, mais aussi de notre excellent service de pièces de rechange, de kits de pièces de rechange individuels et de l'envoi de pièces de rechange sous 24 heures.

Téléchargements

- Information produit: Sécurité de service et fourniture assurée de pièces de rechange PDF 541 KB

- Information produit: Paquets de modernisation pour les machines d'essais statiques et dynamiques - de plus de 50 fabricants PDF 1 MB

- Information produit: Modernisation Hegewald & Peschke PDF 304 KB

- Information produit: Modernisation Machines d’essais statiques PDF 1 MB

Questions fréquemment posées sur la modernisation de machines d’essais

Une machine d'essai universelle rétrofitée est une machine d'essai universelle qui a été mise au niveau le plus récent de la technologie, sous forme d'une modernisation. Qu'il s'agisse de machines d'essais statiques, dynamiques, automatisées ou autres, ZwickRoell modernise toutes les machines et appareils d'essais - même ceux d'autres fabricants.

La modernisation d'une machine d'essai comprend, outre le remplacement de l'électronique, l'entraînement AC, la dernière génération du logiciel d'essai testXpert, les capteurs les plus récents et également les accessoires.

Plus de 50 fabricants tiers ont déjà été modernisés par ZwickRoell. La machine d'essai et l'électronique sont alors mises au niveau le plus récent de la technologie. Que vous possédiez une machine d'essai Instron, MTS, Shimadzu, Hegelwald & Peschke, Galdabini, Schneck ou d'autres fabricants, nous la modernisons en profondeur afin que vous puissiez de nouveau effectuer vos essais, en toute sécurité et conformément aux normes pour les prochaines années.

Après la modernisation d'un modèle d'une autre marque par ZwickRoell, nous devenons votre interlocuteur unique. Qu'il s'agisse de pièces de rechange, d'adaptations de logiciels, d'extension d'accessoires ou de demandes d’étalonnage. Après la modernisation, vous disposez d'une machine d'essai en tout point similaire à une machine ZwickRoell neuve. Vous profitez ainsi de l’excellence de notre service.