Numune boyutu test sonuçlarını etkiler

Kesit ölçümü, metal, plastik, kompozit veya diğer malzemelerden yapılmış sağlam bir numunenin kalınlığını ve genişliğini belirlemektedir.

Malzemenin yük kapasitesini belirlemek için, numune daha sonra bir çekme testine veya bükme testine tabi tutulur. Gerilme veya eğilme gerginliğini doğru bir şekilde belirlemek için, kesit alanı için tam ölçüm yapılması gerekir.

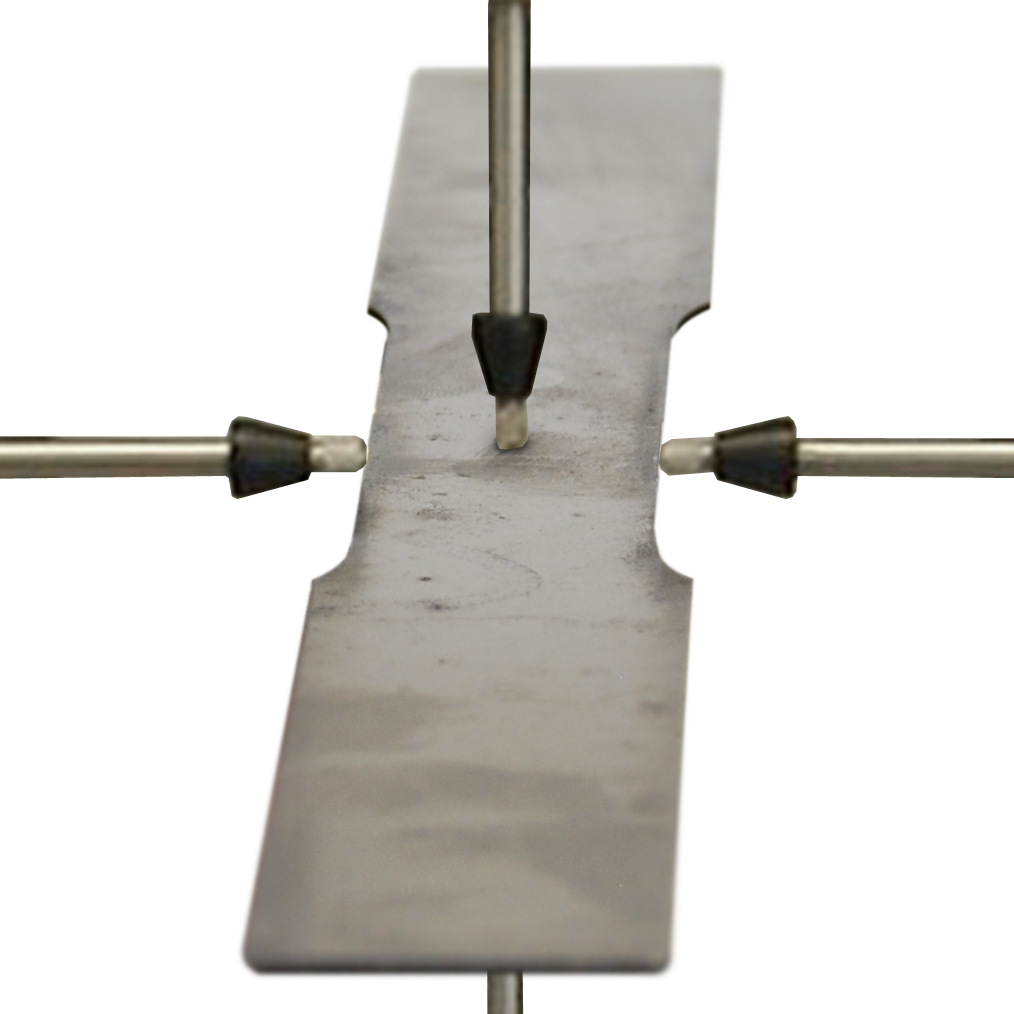

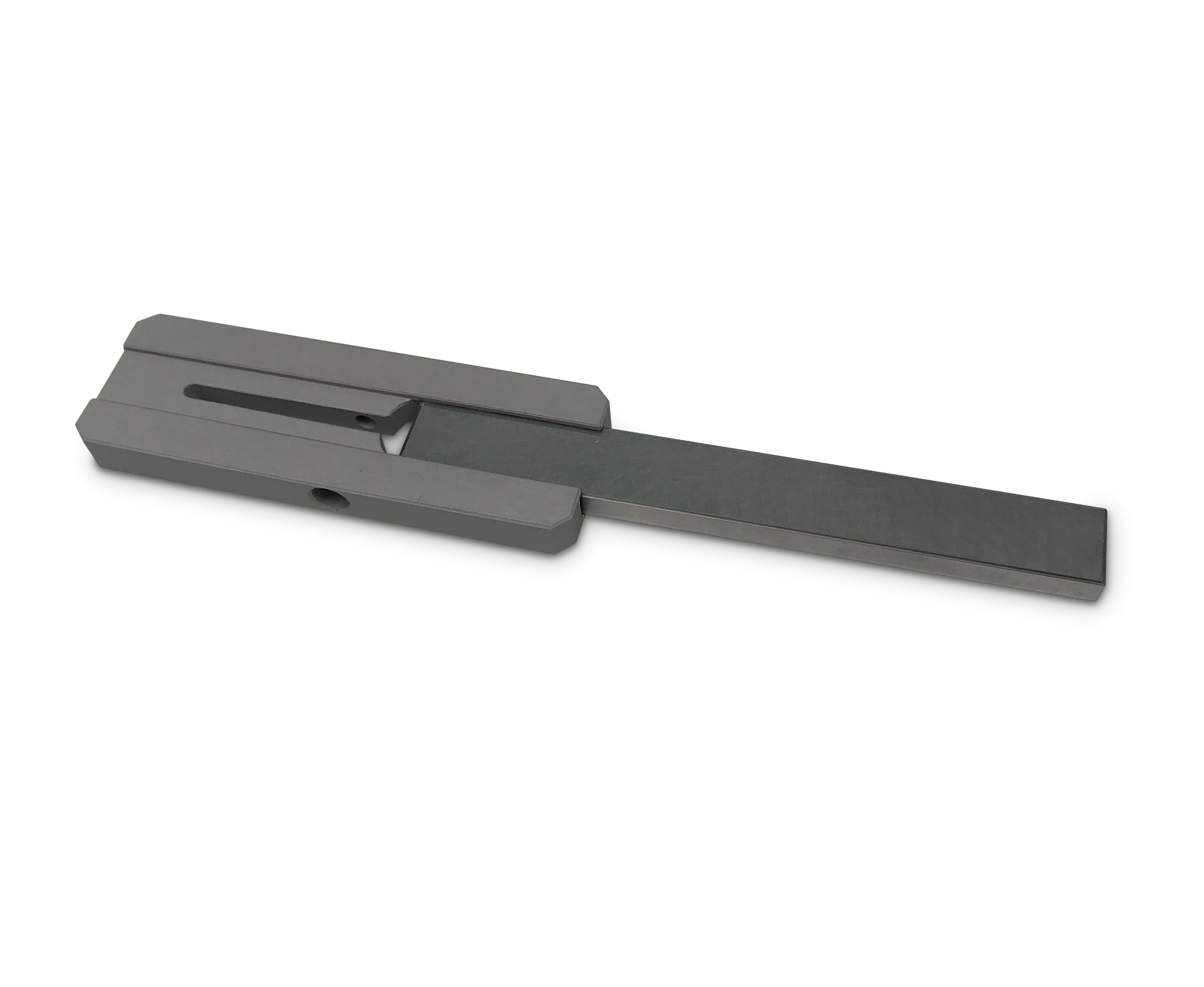

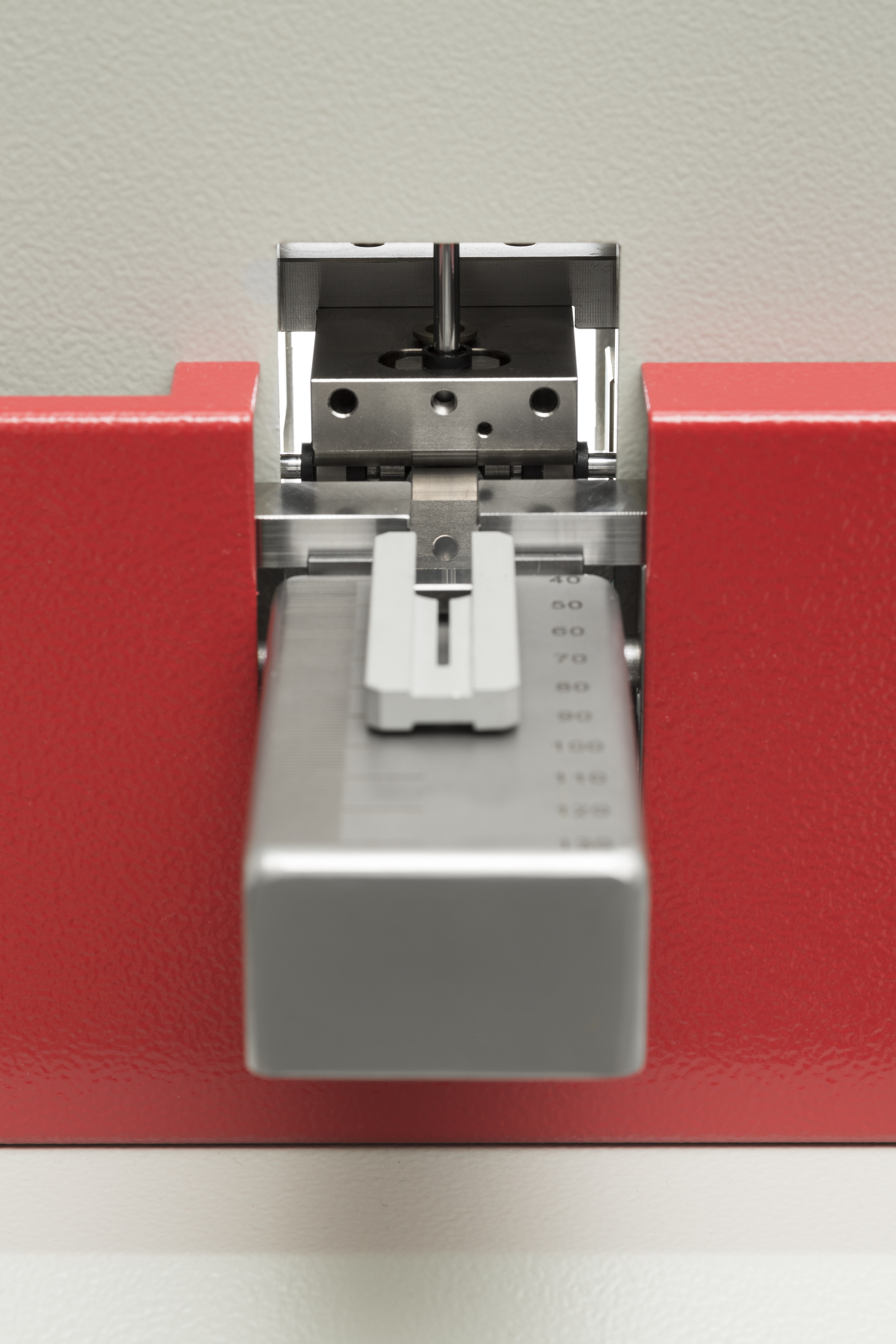

ZwickRoell, numune kalınlığının ve numune genişliğinin hassas bir şekilde belirlenmesi için enine kesit ölçüm cihazları sunar. Cihazın merkezinde, dört artımlı ölçüm duyargası,monte edildiğikapalı bir gövdede bulunur. Numunenin kalınlığı ve genişliği, iki tuş ile diferansiyel olarak ölçülür.

Sensörlerin değerleri elektronik bir sistem tarafından algılanır, bir PLC kontrol ve veri bağlantısı sağlar. Genişlikte ve kalınlık yönünde bir merkezleme, kesit ölçümü sırasında doğru hizalanmasını ve güvenli bir şekilde konumlanmasını sağlamaktadır. İşlem, ölçülen değerlerin okunabileceği renkli bir dokunmatik panel üzerinden gerçekleştirilir. Burada cihazın temel ayarlarını da yapılandırabilirsiniz.

Kesit ölçümümüz güvenilir test sonuçları sağlar

Kesit ölçüm cihazlarının ölçüm aralığı ve doğruluğu

| Açıklama | Fiyat | |

| Açıklama | CMU30 | |

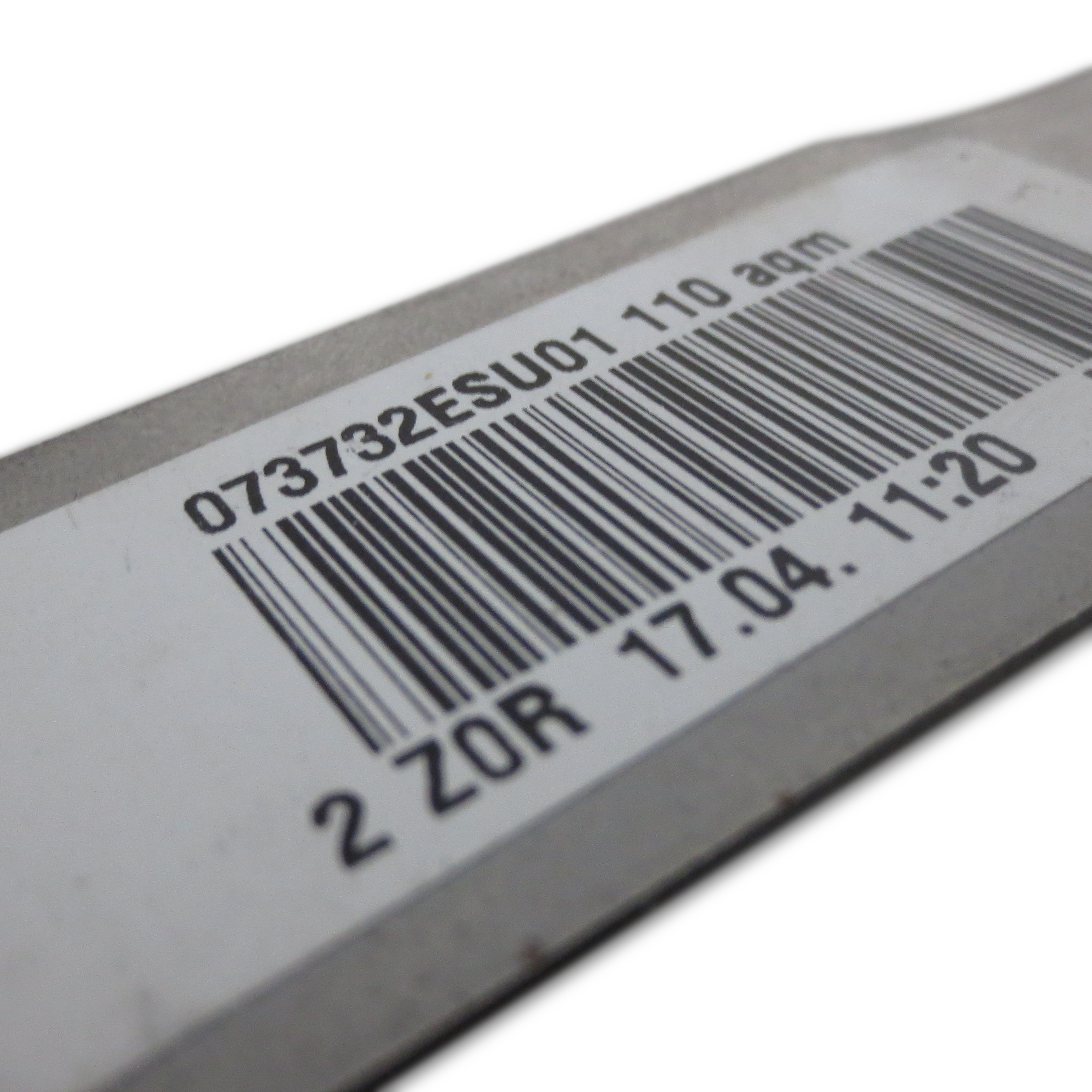

| Ürün No. | 1007665 | |

| Kapsama/Doğruluk | ||

| Kapsama kalınlığı | 0,2 ... 30 | mm |

| Kapsama genişliği | 6 ... 40 | mm |

| Çözünürlük | < 0,01 | µm |

| Tekrarlama doğruluğu1 | ±1 | µm |

| Ağırlık | 37 | kg |

- ölçü bloğunda

| Açıklama | Fiyat | |

| Açıklama | CMU80 | |

| Ürün No. | 1014919 | |

| Kapsama/Doğruluk | ||

| Kapsama kalınlığı | 5 ... 80 | mm |

| Kapsama genişliği | 10 ... 60 | mm |

| Çözünürlük | < 0,01 | µm |

| Tekrarlama doğruluğu1 | ±2 | µm |

| Ağırlık | 97 | kg |

- ölçü bloğunda

| Açıklama | Fiyat | |

| Açıklama | CMU30 | |

| Numuneler | ||

| Form | Düz numuneler | |

| Kalınlık, maks. | 30 | mm |

| Genişlik, maks. | 40 | mm |

| Paralel uzunluk, min. | 60 | mm |

| Tüm uzunluk, min. | 100 | mm |

| Açıklama | Fiyat | |

| Açıklama | CMU80 | |

| Numuneler | ||

| Form | Yuvarlak ve düz numuneler | |

| Kalınlık, maks. | 80 | mm |

| Genişlik, maks. | 70 | mm |

| Paralel uzunluk, min. | 60 | mm |

| Tüm uzunluk, min. | 320 | mm |