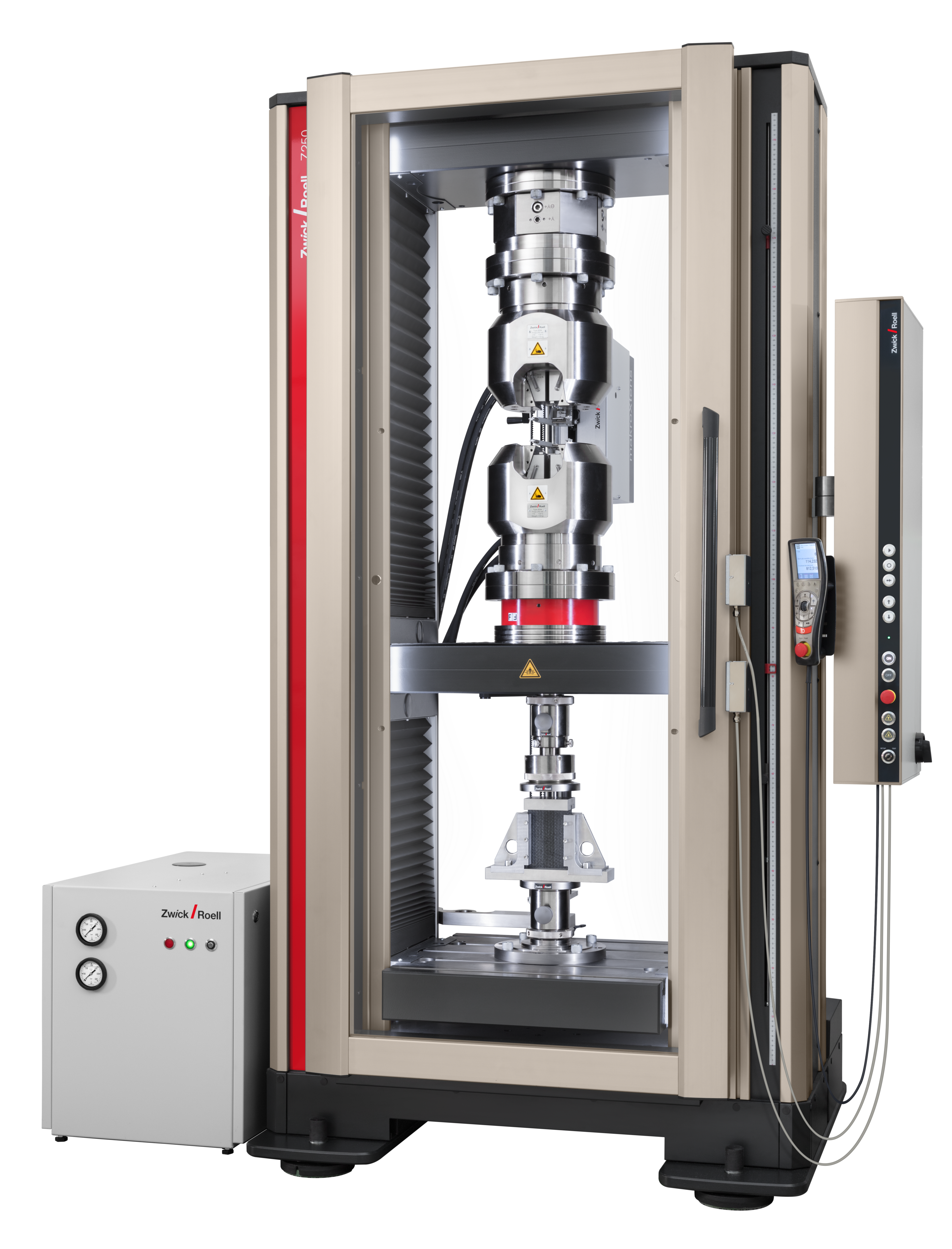

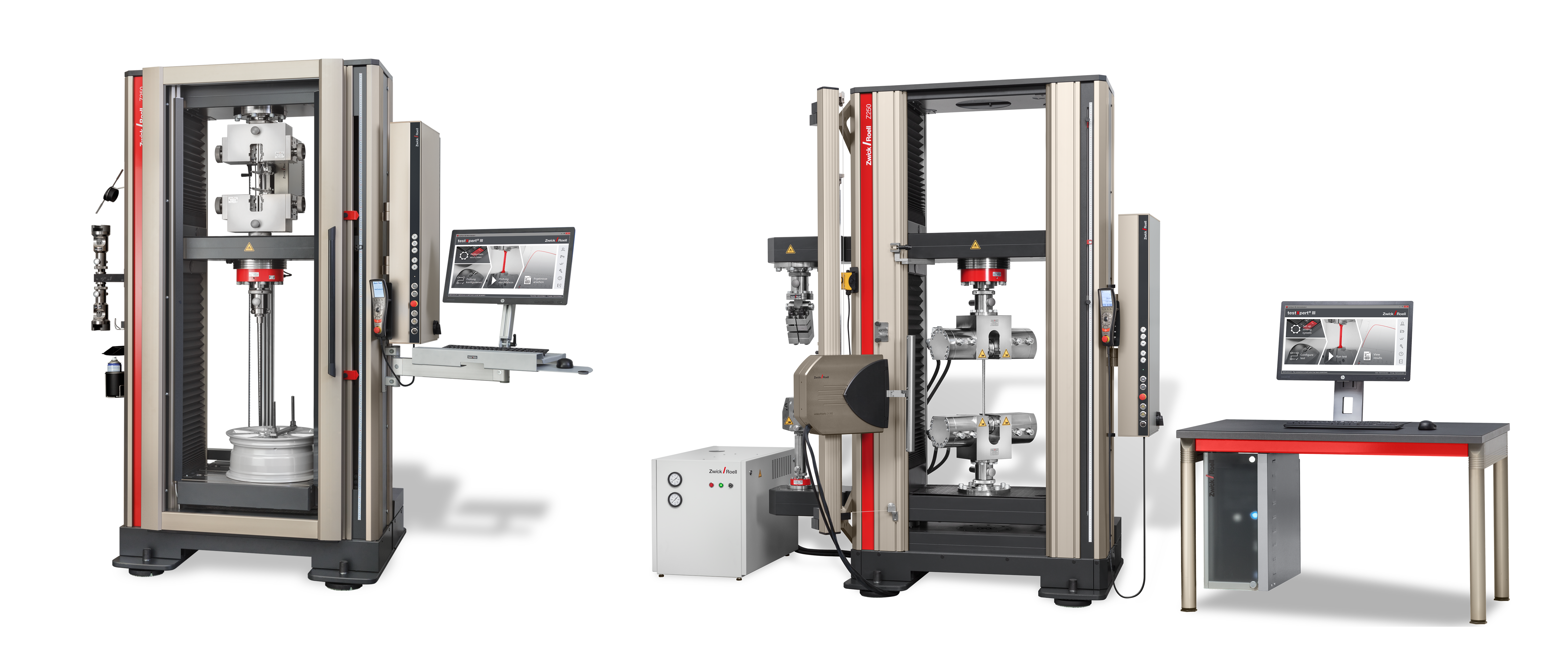

可以满足各种测试需求以及所有应用领域的完美系统

AllroundLine 是一款可定制且功能非常全面的试验机。它可用作立式试验机(包括型号 Z100、Z150、Z250)和台式试验机(型号 Z010、Z020、Z030、Z050、Z100、Z150)。

AllroundLine 试验机适合于所有领域的应用。久经验证的操作概念与灵活的模块化试验机机架设计相结合,使 AllroundLine 成为高要求测试应用(例如质量控制或研究项目)的理想解决方案。AllroundLine 的所有部件(包括机械部件、电子原件、测试软件以及其他配件)均在 ZwickRoell 德国工厂研发制造,因此能够无缝地配合使用。

- 可以选择39种不同的标准试验机型号,优化了测试任务的处理

- 有立式试验机和台式试验机可供选择

- 模块化设计提供最大的灵活性和扩展选项

- 多种配套附件可供选择

- 当必须进行许多不同的测试时,多区域概念降低了操作和购置成本。

根据试验力范围的特性

AllroundLine试验系统包括台式和立式试验机。

| 型号 | 电源输入规格 | 试验载荷 Fmax [kN] | 驱动 | 订货号 | |||

| 型号 [kW] | 满载功耗,约 [kVA] | 横梁速度vmin ... vmax [mm/min] | 横梁回程速度,最大值 [mm/min] | 驱动功率 | |||

| Z100 SN | 4 | 6 | 100 | 0.00005 ...10001 | 15001 | 1035012 | |

| Z100 ST | 4 | 6 | 100 | 0.00005 ...10001 | 15001 | 1035013 | |

| Z100 SH | 4 | 6 | 100 | 0.00005 ...10001 | 15001 | 10350142 | |

| Z150 SN | 4 | 6 | 150 | 0.00005 ...9001 | 15001 | 4000 | 1035017 |

| Z150 ST | 4 | 6 | 150 | 0.00005 ...9001 | 15001 | 4000 | 1035020 |

| Z250 SN | 4 | 6 | 250 | 0.00005 ...600 | 10001 | 1031325 | |

| Z250 ST | 4 | 6 | 250 | 0.00005 ...600 | 10001 | 1035023 | |

| Z250 SR | 4 | 6 | 250 | 0.00005 ...600 | 10001 | 1035022 | |

| Z250 SH | 4 | 6 | 250 | 0.00005 ...600 | 10001 | 10350242 | |

| Z250 SE | 4 | 6 | 250 | 0.00005 ...600 | 10001 | 10329962 | |

| Z250 SNS | 4 | 6 | 250 | 0.00005 ...600 | 10001 | 1035025 | |

- 数值适用于自动模式下安全门关闭的试验机,以及没有安全装置的试验机。对于安全门打开的试验机,速度降低至600 mm/min。

- 必须使用随附的安装套件用螺栓将这些试验系统固定到地面上。

AllroundLine试验系统包括台式和立式试验机。

| 型号 | 电源输入规格 | 试验载荷 Fmax [kN] | 驱动 | 订货号 | |||

| 型号 [W] | 满载功耗,约 [kVA] | 横梁速度vmin ... vmax [mm/min] | 横梁回程速度,最大值 [mm/min] | 驱动功率 [W] | |||

| Z005 TN | 500 | 2 | 5 | 0.0005 ...30001 | 30001 | 500 | 1004473 |

| Z005 TNW | 500 | 2 | 5 | 0.0005 ...30001 | 30001 | 500 | 1004475 |

| Z005 TH | 500 | 2 | 5 | 0.0005 ...30001 | 30001 | 500 | 1004476 |

| Z005 THW | 500 | 2 | 5 | 0.0005 ...30001 | 30001 | 500 | 1004477 |

| Z005 TE | 500 | 2 | 5 | 0.0005 ...30001 | 30001 | 500 | 10044782 |

| Z010 TN | 500 | 2 | 10 | 0.0005 ...20001 | 30001 | 500 | 1004479 |

| Z010 TNW | 500 | 2 | 10 | 0.0005 ...20001 | 30001 | 500 | 1004480 |

| Z010 TH | 500 | 2 | 10 | 0.0005 ...20001 | 30001 | 500 | 1004481 |

| Z010 THW | 500 | 2 | 10 | 0.0005 ...20001 | 30001 | 500 | 1004482 |

| Z010 TE | 500 | 2 | 10 | 0.0005 ...20001 | 30001 | 500 | 10044832 |

| Z010 TEW | 500 | 2 | 10 | 0.0005 ...20001 | 30001 | 500 | 10044842 |

| Z020 TN | 1 | 2.3 | 20 | 0.0005 ...10001 | 15001 | 500 | 1004485 |

| Z020 TNW | 1 | 2.3 | 20 | 0.0005 ...10001 | 15001 | 500 | 1004486 |

| Z020 TH | 1 | 2.3 | 20 | 0.0005 ...10001 | 15001 | 500 | 1004487 |

| Z020 THW | 1 | 2.3 | 20 | 0.0005 ...10001 | 15001 | 500 | 1004488 |

| Z020 TE | 1 | 2.3 | 20 | 0.0005 ...10001 | 15001 | 500 | 10044892 |

| Z020 TEW | 1 | 2.3 | 20 | 0.0005 ...10001 | 15001 | 500 | 10044902 |

| Z030 TH | 1 | 2.3 | 30 | 0.0005 ...10001 | 15001 | 1000 | 1004491 |

| Z030 THW | 1 | 2.3 | 30 | 0.0005 ...10001 | 15001 | 1000 | 1004492 |

| Z030 TE | 1 | 2.3 | 30 | 0.0005 ...10001 | 15001 | 1000 | 10044932 |

| Z030 TEW | 1 | 2.3 | 30 | 0.0005 ...10001 | 15001 | 1000 | 10044942 |

| Z050 TH | 1 | 2.3 | 50 | 0.0005 ...600 | 10001 | 1000 | 1004495 |

| Z050 THW | 1 | 2.3 | 50 | 0.0005 ...600 | 10001 | 1000 | 1004496 |

| Z050 TE | 1 | 2.3 | 50 | 0.0005 ...600 | 10001 | 1000 | 10044982 |

| Z050 TEW | 1 | 2.3 | 50 | 0.0005 ...600 | 10001 | 1000 | 10044992 |

| Z100 THW | 4 | 6 | 100 | 0.0001 ...15001 | 25001 | 4000 | 1004500 |

| Z100 TEW | 4 | 6 | 100 | 0.0001 ...15001 | 25001 | 4000 | 10045012 |

| Z150 TL | 4 | 5.5 | 150 | 0.0001 ...9001 | 15001 | 4000 | 1004503 |

- 数值适用于自动模式下安全门关闭的试验机,以及没有安全装置的试验机。对于安全门打开的试验机,速度降低至600 mm/min。

- 支脚随试验系统一起交付。