- Universal

- 5kN - 250kN

- Tensile test

- Compression test

- Flexure test

- Universal testing applications in a medium force range

The perfect system for individual testing requirements and for all applications

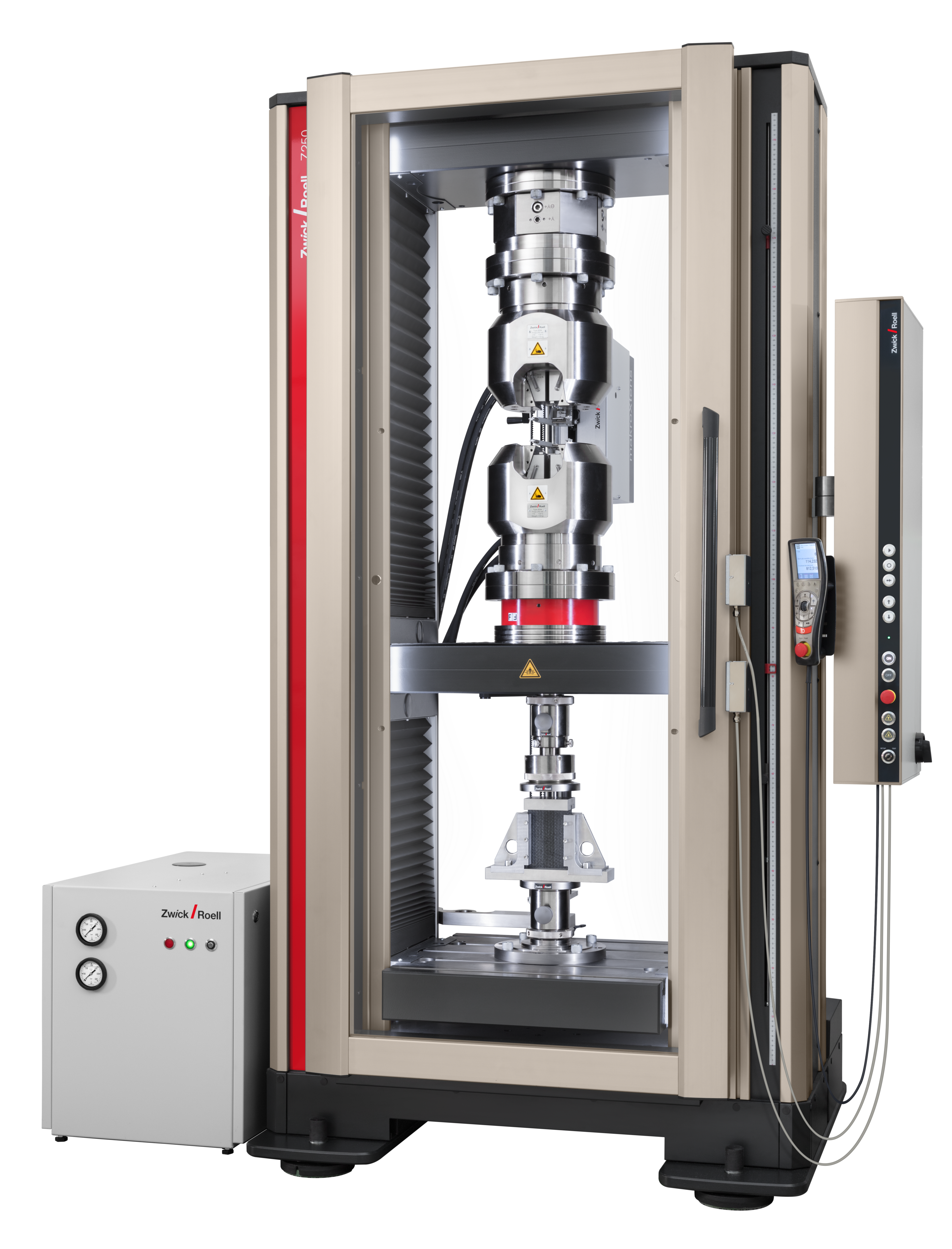

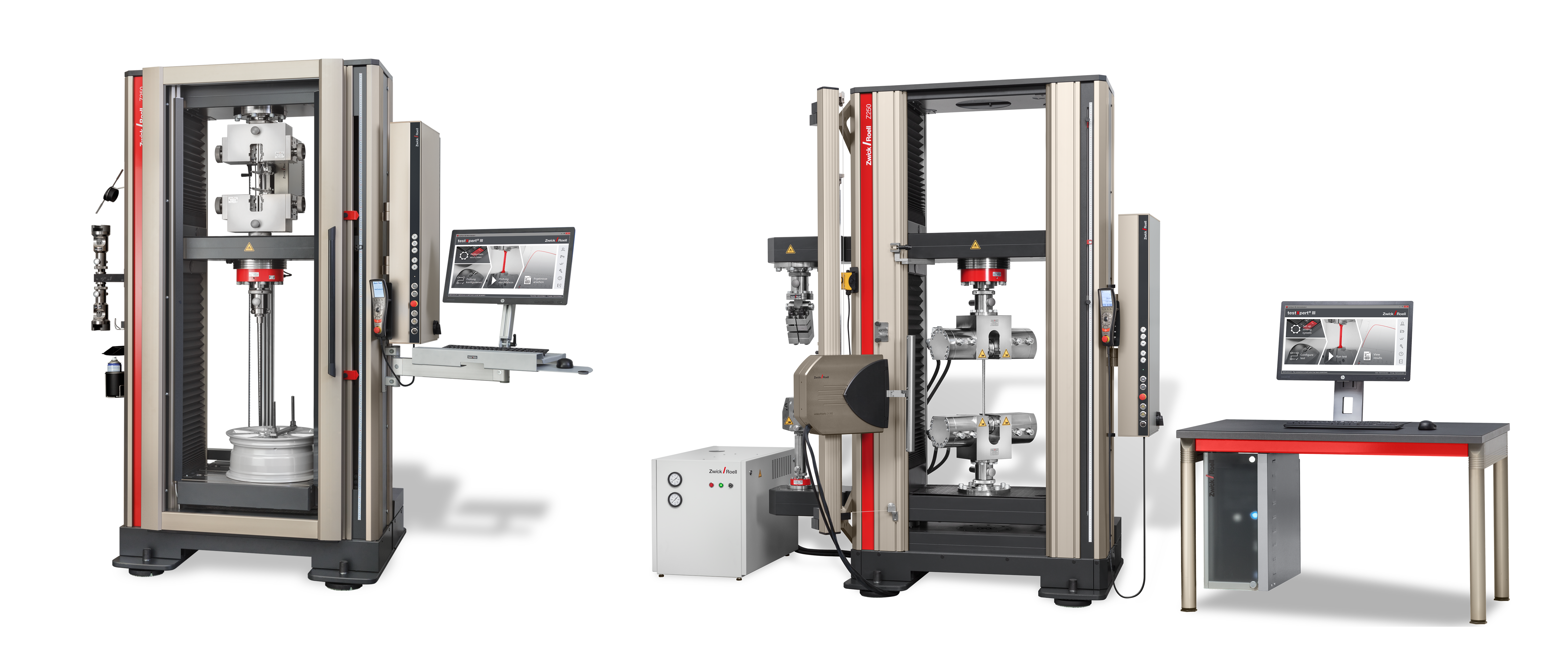

The AllroundLine is our customizable and highly versatile testing machine. It is available as a floor-standing testing machine (including models Z100, Z150 and Z250) and as a table-top testing machine (models Z010, Z020, Z030, Z050, Z100, Z150).

AllroundLine is suitable for applications in all fields. A proven operating concept combined with flexible, modular load-frame design makes the AllroundLine an optimal solution for demanding testing applications, whether for quality control or for research projects. Development and manufacture of AllroundLine, including all mechanical, electronic and software components, together with the comprehensive range of accessories, takes place at ZwickRoell's production facility in Germany, enabling optimum matching of all items.

- Selection of 39 different standard machine types for optimal processing of test tasks

- Available as a floor-standing testing machine and table-top testing machine

- Modular design for maximum flexibility and expansion options

- Wide selection of coordinated accessories

- The multi-area concept reduces operating and acquisition costs when many different tests have to be performed.

Technical overview

- AllroundLine is available with test speeds from 0.00005 to 3000 mm/min, depending on type. Testing machine speed is independent of the test load.

- The high test-speed range can be used without restriction. In addition, test loads up to 110% of machine nominal load are permissible to compensate for heavy combinations of test fixtures, accessories etc.

- AllroundLine is available for test loads up to 250 kN and with test-area heights from 1030 mm to 2560 mm.

- AllroundLine can be operated with standard commercial PCs or laptops and requires no special expansion cards.

Properties according to force range

The AllroundLine testing systems include table top and floor-standing testing machines.

| Type | Test load Fmax [kN] | Drive system | Power input specifications | Item No. | ||

| Crosshead speed vmin ... vmax [mm/min] | Crosshead return speed, max. [mm/min] | Driving power | Power consumption (full load), approx. [kVA] | |||

| Z100 SN | 100 | 0.00005 ... 10001 | 15001 | 6 | 1035012 | |

| Z100 ST | 100 | 0.00005 ... 10001 | 15001 | 6 | 1035013 | |

| Z100 SH | 100 | 0.00005 ... 10001 | 15001 | 6 | 10350142 | |

| Z150 SN | 150 | 0.00005 ... 9001 | 15001 | 4000 | 6 | 1035017 |

| Z150 ST | 150 | 0.00005 ... 9001 | 15001 | 4000 | 6 | 1035020 |

| Z250 SN | 250 | 0.00005 ... 600 | 10001 | 6 | 1031325 | |

| Z250 ST | 250 | 0.00005 ... 600 | 10001 | 6 | 1035023 | |

| Z250 SR | 250 | 0.00005 ... 600 | 10001 | 6 | 1035022 | |

| Z250 SH | 250 | 0.00005 ... 600 | 10001 | 6 | 10350242 | |

| Z250 SE | 250 | 0.00005 ... 600 | 10001 | 6 | 10329962 | |

| Z250 SNS | 250 | 0.00005 ... 600 | 10001 | 6 | 1035025 | |

- Values apply to machines with the safety doors closed in automatic mode and to machines without safety devices. For machines with the safety door open, the speed is reduced to 600 mm/min.

- These testing systems must be bolted to the floor using the mounting kit supplied.

The AllroundLine testing systems include table top and floor-standing testing machines.

| Type | Test load Fmax [kN] | Drive system | Power input specifications | Item No. | ||

| Crosshead speed vmin ... vmax [mm/min] | Crosshead return speed, max. [mm/min] | Driving power [W] | Power consumption (full load), approx. [kVA] | |||

| Z005 TN | 5 | 0.0005 ... 30001 | 30001 | 500 | 2 | 1004473 |

| Z005 TNW | 5 | 0.0005 ... 30001 | 30001 | 500 | 2 | 1004475 |

| Z005 TH | 5 | 0.0005 ... 30001 | 30001 | 500 | 2 | 1004476 |

| Z005 THW | 5 | 0.0005 ... 30001 | 30001 | 500 | 2 | 1004477 |

| Z005 TE | 5 | 0.0005 ... 30001 | 30001 | 500 | 2 | 10044782 |

| Z010 TN | 10 | 0.0005 ... 20001 | 30001 | 500 | 2 | 1004479 |

| Z010 TNW | 10 | 0.0005 ... 20001 | 30001 | 500 | 2 | 1004480 |

| Z010 TH | 10 | 0.0005 ... 20001 | 30001 | 500 | 2 | 1004481 |

| Z010 THW | 10 | 0.0005 ... 20001 | 30001 | 500 | 2 | 1004482 |

| Z010 TE | 10 | 0.0005 ... 20001 | 30001 | 500 | 2 | 10044832 |

| Z010 TEW | 10 | 0.0005 ... 20001 | 30001 | 500 | 2 | 10044842 |

| Z020 TN | 20 | 0.0005 ... 10001 | 15001 | 500 | 2.3 | 1004485 |

| Z020 TNW | 20 | 0.0005 ... 10001 | 15001 | 500 | 2.3 | 1004486 |

| Z020 TH | 20 | 0.0005 ... 10001 | 15001 | 500 | 2.3 | 1004487 |

| Z020 THW | 20 | 0.0005 ... 10001 | 15001 | 500 | 2.3 | 1004488 |

| Z020 TE | 20 | 0.0005 ... 10001 | 15001 | 500 | 2.3 | 10044892 |

| Z020 TEW | 20 | 0.0005 ... 10001 | 15001 | 500 | 2.3 | 10044902 |

| Z030 TH | 30 | 0.0005 ... 10001 | 15001 | 1000 | 2.3 | 1004491 |

| Z030 THW | 30 | 0.0005 ... 10001 | 15001 | 1000 | 2.3 | 1004492 |

| Z030 TE | 30 | 0.0005 ... 10001 | 15001 | 1000 | 2.3 | 10044932 |

| Z030 TEW | 30 | 0.0005 ... 10001 | 15001 | 1000 | 2.3 | 10044942 |

| Z050 TH | 50 | 0.0005 ... 600 | 10001 | 1000 | 2.3 | 1004495 |

| Z050 THW | 50 | 0.0005 ... 600 | 10001 | 1000 | 2.3 | 1004496 |

| Z050 TE | 50 | 0.0005 ... 600 | 10001 | 1000 | 2.3 | 10044982 |

| Z050 TEW | 50 | 0.0005 ... 600 | 10001 | 1000 | 2.3 | 10044992 |

| Z100 THW | 100 | 0.0001 ... 15001 | 25001 | 4000 | 6 | 1004500 |

| Z100 TEW | 100 | 0.0001 ... 15001 | 25001 | 4000 | 6 | 10045012 |

| Z150 TL | 150 | 0.0001 ... 9001 | 15001 | 4000 | 5.5 | 1004503 |

- Values apply to machines with the safety doors closed in automatic mode and to machines without safety devices. For machines with the safety door open, the speed is reduced to 600 mm/min.

- Support legs are included in the delivery of this testing system.

Downloads

- Product information: AllroundLine, Fmax 5-100 kN PDF 1 MB

- Product Information: AllroundLine, Fmax 100-150 kN PDF 2 MB

- Product information: AllroundLine, Fmax 150 kN PDF 719 KB

- Product information: AllroundLine, Fmax 250 kN PDF 2 MB

- Product information: Floor-standing AllroundLine testing machine with side test area PDF 514 KB