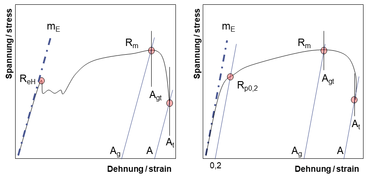

Yield strength Re and offset yield Rp 0.2

The yield strength Re is a material characteristic value and is determined using tensile testing (e.g. ISO 6892 standard series for metallic materials or ISO 527 standard series for plastics and composites). The yield strength Re denotes the stress during a tensile test up to which a material can be elastically deformed. The yield strength is specified in MPa (megapascal) or N/mm².

What is yield strength? Upper yield strength Lower yield strength Minimum yield strength Offset yield Testing machines Tensile test Tensile strength

What describes the yield point?

It is often possible to determine both an upper yield strength ReH value and a lower yield strength ReL value.

The upper yield point designates the stress up to which no permanent plastic deformation occurs in a material under tensile loading. The material does undergo deformation, however after withdrawal of the tensile stress it returns to its original form. If the upper yield point is exceeded, the plastic or permanent deformation begins; in tensile testing the specimen is irreversibly elongated.

The yield strength Re and tensile strength Rm values can be used to calculate the yield strength ratio:

Re / Rm

The yield strength ratio is a measurement of strain hardening up to the tensile strength. The yield strength ratio thus indicates how much tensile stress margin is available in a design/construction until the failure of the material clearly sets in.

Often the yield point of materials is not pronounced and therefore cannot be clearly determined in the tensile test. In these cases, the offset yield is determined. As a rule, the offset yield is determined at 0.2% plastic elongation, hence the designation of the characteristic value with Rp 0,2.

Upper Yield Point ReH

The highest stress value before its significant first drop is designated as the upper yield strength ReH. At this point the material undergoes plastic deformation. If the yield strength is very pronounced, the material begins to flow, whereby the stress decreases slightly, but the elongation continues to increase. The lowest tensile stress during flow corresponds to the lower yield strength ReL. This effect occurs exclusively on steel with little or no alloy.

The upper yield strength is the highest tensile stress before flow and is defined by the metals tensile standard ISO 6892-1 as follows: After reaching the stress maximum, there must be a stress reduction of at least 0.5% and a subsequent flow of at least 0.05% without the tensile stress exceeding the upper yield strength again.

Lower Yield Point ReL

The lower yield strength ReL is the lowest stress value in the flow range of the material following the upper yield strength ReH, whereby transient oscillation occurrences (e.g. due to a change in force) may not be taken into account.

In a case where the upper yield strength is not recognized (the reduction in force is less than 0.5%) or yielding occurs at a fairly constant force over a larger range, this stress value is generally referred to as just yield strength Re.

What is the Minimum Yield Strength?

The minimum yield strength is, on one hand, the value for the minimum yield strength which is stably reached or exceeded for a specific material with the appropriate heat treatment. On the other hand, it is a maximum tensile stress value which must be taken as a basis for the design of components and supporting structures so that permanent deformation in the intended use of the components and supporting structures can be safely avoided.

For the material supplier, the minimum yield strength therefore becomes the minimum value that must be achieved, and for the material user the maximum value that must not be exceeded during design.

How Does the Yield Point Apply to Steel?

The yield point indicates the end of the elastic behavior of the material and the start of the plastic behavior. This means that if the yield point is exceeded, the material is irreversibly, or in other words permanently, plastically deformed.

As a rule, components and constructions can no longer be used safely if the yield point is exceeded even locally or partially.

Offset yield

The offset yield is an arbitrary point on the stress-strain curve. It is mainly used for materials that do not have a pronounced yield strength. With a continuous transition between the material’s elastic and plastic range, the yield strength cannot be clearly defined. Often an offset yield of 0.2% is used.

What is the Offset Yield Rp0.2?

The offset yield Rp0.2 is the tensile stress in a uniaxial tensile test, at which the plastic elongation corresponds to a percentage of 0.2% of the extensometer gauge length. Based on the initial length, the specimen was elongated by 0.2% in the plastic range.

Cold-rolled or cold formed materials do not have a pronounced yield point. Generally for these materials an offset yield of 0.2 % (Rp0,2) is determined and specified. This 0.2 % offset yield can always be clearly determined from the stress-strain diagram (which is not always the case for an upper yield point).