Interlaminar shear strength (ILSS) to ASTM D2344

The interlaminar shear strength (ILSS) of fiber reinforced composites describes the shear strength between laminate planes of composites and is determined using the short beam shear test. Performance of the test is described in standards ASTM D2344, EN 2563 and EN ISO 14130.

Objective and performance Specimens & dimensions Calculation ILSS test fixture Related testing machines Downloads

Objective of the ILSS test and performance to ASTM D2344

The interlaminar shear strength of laminates with a brittle matrix, made of epoxy resin for example, is typically determined using a short beam shear test (SBS). This takes advantage of the fact that shear stresses always occur in a flexure test. If the support span is small compared to the specimen thickness, the shear stresses that occur are very large compared to the normal stresses generated by the bending moment. In this way, a shear stress fracture can be generated in brittle matrix materials, enabling measurement of the shear strength.

The shear strength of the matrix material or the quality of the fiber-matrix bonding can be characterized depending on the break type.

The short beam shear test can be performed according to different standards, including ASTM D2344, EN 2563 or EN ISO 14130. Specimen length, specimen width and support span for the nominal specimen geometry are defined in relation to the specimen thickness, whereby the defined ratios differ within the respective standards. The specifications for the diameter of the compression die and supports also differ in each case.

This test method is relatively simple to employ and requires a simple tool that has good alignment capabilities, as well as accurate centering of the die. For this reason, the method is often used in quality control and is suitable for comparing materials.

However, the method determines only in-plane shear properties, since compressive stress peaks usually arise near the upper anvil and can influence the measured results.

Specimens and dimensions for measurement of the interlaminar shear strength (ILSS)

Testing of standard laminates:

- In materials development, standard laminates with a thickness of 2 mm are tested. Depending on the standard used, the span is 8 or 10 mm and must be set to an accuracy of up to ±0.1 mm. EN 2563 defines a very small tolerance of ±0.02 mm for the flexure tup.

- ZwickRoell test tools simplify the tasks of specimen centering and setting the span, as well as precise parallel alignment of the supports.

Testing of laminates made of finished structures:

- Laminates made of profiles, plates, or components often have other thicknesses. In these cases, it is important that the relationship of the span to the laminate thickness is observed. The span must be able to be set accurately for each test series with minimum effort and the centering should have to be adjusted only once.

- ZwickRoell's ILSS test fixture is equipped with a counter lead screw for this purpose. The supports can be adjusted to the desired span while maintaining the center point. Defined measuring surfaces on the sides of the supports make it possible to accurately measure the span.

Test fixture for determination of the interlaminar shear strength (ILSS)

Applications: Determination of the interlaminar shear strength (ILSS) to ASTM D2344, EN 2563, ISO 14130, EN 2377

Function description: The fixture is a 3-point flexure test kit. ILSS tests represent a typical quality control method. They are suitable for comparing materials. In view of the small span it is particularly important for the die to be aligned exactly with the upper anvils. This is ensured by means of the die arm. The arm can be fixed for installation of the specimen. In addition, a temperature sensor can be attached to the die arm in close proximity to the specimen for tests in temperature chambers. At 10 mm, the anvil/thickness ratio is very short. As a consequence, high shear forces and relatively low bending moments arise in the specimen. The method provides only apparent shear properties, as stress peaks occur close to the upper anvil.

Advantages of the ILSS test fixture from ZwickRoell:

- Precise centering of upper anvil in relation to the die

- Easy adjustment of the upper anvils

- Clamping option for temperature sensor near the specimen

- Forces up to 20 kN possible

- Quick change upper anvils and dies

- With the optionally attainable lead screw adjuster, the upper anvils can be quickly and precisely adjusted for changing laminate thicknesses

Frequently asked questions about shear strength / interlaminar shear strength

The determination of the interlaminar shear strength of fiber-reinforced composites is used for quality monitoring of shear-stressed components. Interlaminar shear strength (ILSS) describes the shear strength between laminate planes of composites.

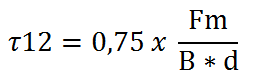

To calculate the interlaminar shear strength (ILSS), we use the following equation, where

Fm = maximum compressive force in Newton

B = measured specimen width

d = measured specimen thickness

Take advantage of the leading testing software in materials testing

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!