Flexible integration

The flexibility of testXpert allows it to easily integrate into your testing processes and optimize your workflow. With a single testing software solution you can operate various testing machines, testing instruments and applications. This reduces the time required for training and allows you to centrally record and evaluate all test results with uniform and standardized interfaces.

Optimal integration One software solution for everything testXpert building blocks

For a more effective workflow: optimal integration in your processes

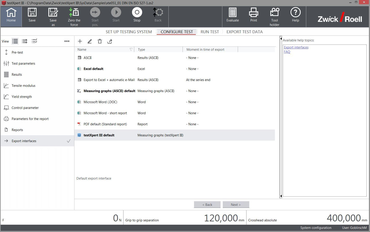

testXpert fits perfectly into your processes and optimally integrates in your IT environment. This is ensured by a wide range of import and export interfaces. Data is automatically read and written, saving you a lot of time and preventing incorrect entries. Effective optimization of your processes!

testXpert can also be flexibly expanded with interfaces and functions at a later date. And even with this high level of flexibility, testXpert remains simple to operate and clearly laid out.

- Import: Thanks to the flexible interfaces, testXpert can read data from ERP or LIM systems. This saves time and prevents incorrect entries.

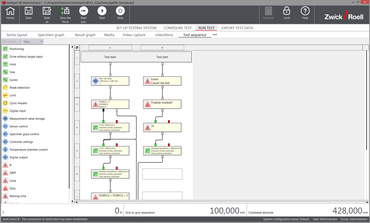

- Test: You can adapt testXpert to your testing process—from the layout of the interface down to every detail of your test sequence.

- Export: testXpert offers additional possibilities after the test is completed, including test reports, test data output or data management.

Data import

- Data from LIMS, QA, CAQ and ERP systems, such as material data, specimen batch and client data is automatically imported— speeding up your processes.

- Barcode scanning: Automatically read in specimen information—such as specimen dimensions that were measured during the specimen preparation stage—before the test. This again, saves you valuable test time.

- Specimen dimension measuring instruments transfer the measured values directly to testXpert. Data is transferred at the push of a button, and number errors caused by manual entry are a thing of the past.

- testXpert detects and automatically controls all sensors and devices, something the user no longer needs to worry about. Whether an additional load cell, strain gauge or external measurement amplifier, testXpert takes care of everything.

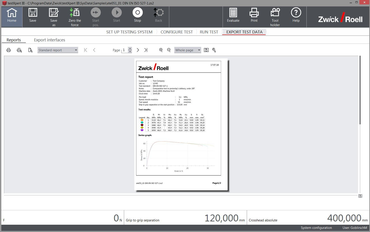

Data export

- Restoring test results in LIMS, QA, CAQ and ERP systems

- Output of test data into the usual applications, e.g. MS Office, qs-STAT, in CSV or ASCII format or into customized solutions

- Automatic test report in Word or PDF format, including output of multiple, different test reports for different target groups (lab manager, customer)

- Test Data Management for centralized evaluation of all tests (testXpert Analytics option)

- Trend Analysis for long-term statistics (testXpert Analytics option)

- Fatigue Data Evaluation (FDE)

With the multi-user license, you can conveniently evaluate test results from other workplaces. testXpert can be installed on any number of computers.

“Redundant data input costs time, is error-prone and frustrates users in the lab. We cannot afford, nor do we want to deal with these issues! With testXpert, we have streamlined and significantly optimized our processes.”

Daniel Carmine Manocchio, Manager Material Technology, Alfred Kärcher SE & Co. KG

>>> Read our customer case study addressing the topic of data integration

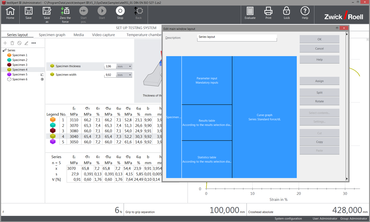

Report per individual requirements and specifications

Whether you need simple or very specific reports, the Report Editor option offers virtually unlimited possibilities. Any change made to the report is updated directly in the preview. Multiple reports can also be defined and saved with the test program.

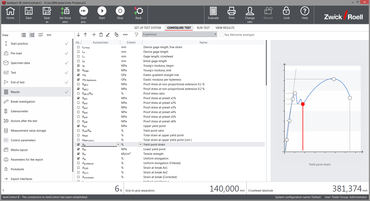

Flexible testing and evaluation

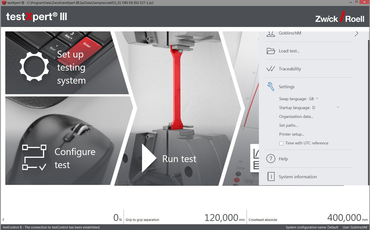

testXpert’s workflow is based on the typical processes of a testing laboratory and takes all requirements and specifications into account.

Adaptation of the interface is flexible, so that it can be perfectly suited for your specific mode of operation. Information that is important for your processes is visualized in every test phase. You can choose from different visualization elements, from the current test force to statistical tables or histograms. You can also select the arrangement and size of the elements according to your liking.

A single software solution for every application and requirement

testXpert is the software solution that fits—100%. This testing software solution incorporates decades of application experience and knowhow covering more than 20 industries. With a single solution, you address all of your requirements, while operation remains clear and simple. This significantly reduces the time required to train employees.

- A single software solution for all testing instruments and testing machines, both static and dynamic. The results from all of your machines can be centrally recorded and evaluated.

- One software solution for the widest range of applications—regardless of material, industry or standard.

- One software solution for every user:

- For the quick learner up to the highest level of flexibility in the field of research,

- For tests according to standard up to fully customized test sequences.

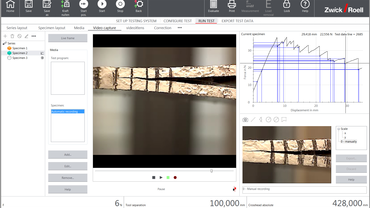

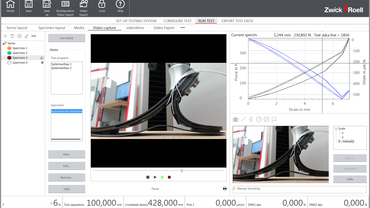

Synchronous Video Capturing for visualization of the test sequence

With the Video Capturing option, a video is recorded in parallel to the test using a webcam or camcorder. Integrated hardware synchronization allows frame-accurate synchronization of testXpert test data and video. During playback of the videos the correlative test data are shown in the curve graph via cross-hairs; alternatively the cross-hairs are used to select any desired line of measured values and the corresponding video image is automatically obtained. This allows accurate retrospective visual assessment of the course of the test, e.g. when, how and where necking, buckling, delamination or change in color of the specimen occurred.