夹持式引伸计:功能齐全,高度准确

夹持式引伸计是初始标距长度恒定的持续应用以及测量次数有限情况下的高性价比解决方案。夹持式引伸计的分辨率高,即使是最小的变形,也可以在试验期间测得。

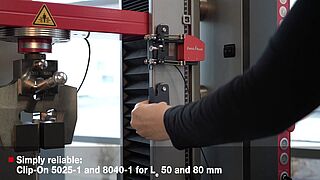

用户手动将夹持式引伸计连接到试样上,这就是引伸计被称为夹持式引伸计的原因。由于它们直接夹在试样上,因此重量轻且易于操作至关重要。

ZwickRoell提供基于应变片的夹持式引伸计,因此称为应变片引伸计或增量夹持式引伸计。

应用

- 根据ISO 527-1/-2 /-4标准测定塑料和纤维增强复合材料的拉伸模量

- 根据ISO 527-1/-2 /-4标准测定塑料和复合材料的泊松比

- 在纤维增强复合材料的±45°剪切试验(面内剪切,IPS)中测定面内剪切性能长度

- 根据ASTM E517和ISO 10113标准测定金属的r值。

- 根据ISO 6892-1方法A1/ASTM E8方法B进行闭环应变速率控制

- 测定塑料的抗压强度或金属压缩方面的杨氏模量

夹持式引伸计常见问题解答

夹持式引伸计通过直接连接到试样上进行应变测量,因此被称为夹持式引伸计。严格来说,它们测量位移变化,该变化由测试软件转换为应变值。

由于夹持式引伸计的分辨率较高,即使变形最小,也能在试验中测得。夹持式引伸计由用户手动连接到试样上,无法自动化。

因为夹持式引伸计由用户直接连接到试样上,因此引伸计必须易于操作。此外,还有多种方式可以将用户的影响降至最小,例如,在连接时锁定初始标距长度,以便初始标距长度设定精确。这大大提高了测试结果的可再现性。

通常,夹持式引伸计限于一个初始标距长度,但有一些变化允许调整或转换为替代标距长度。

重量也很重要,因为夹持式引伸计直接连接到试样上,应将对试样的任何影响均降至最低。

夹持式引伸计用于初始标距长度恒定的标准应用以及次数有限的试验。如果是这种情况,夹持式引伸计就是高性价比解决方案。

应变片位移传感器是一种基于应变片测量材料试样在载荷作用下变形的仪器。

这也包括基于应变片进行测量的夹持式应变片引伸计。位移传感器内的应变片会记录试验期间的机械变形,并将其转换为可测量的电信号。其他引伸计以增量、感应或光学方式进行测量 - 我们随时为您提供建议。

还有应变片位移传感器,它们可以连接到试样的外部,例如用于弯曲试验、压缩试验或部件测试。有关用于压缩、弯曲和部件测试的位移传感器详细信息可以在这里找到。

应变片夹持式引伸计,基于应变片进行测量,具有高精度和高分辨率。这就是为什么即使变形最小,应变片夹持式引伸计也可以在试验期间测得该变形。但是,温度变化也会影响测量,尤其是在环境试验箱中测量时。因此,补偿温度相关的偏差很重要。

根据设计,应变片夹持式引伸计的初始标距长度通常不可调节。设计紧凑、轻巧的应变片夹持式引伸计即使直接放在试样上,对试样的影响也很小。

使用增量夹持式引伸计时,增量刻度已实现最小化。由于设计原因,轻型测量系统非常靠近试样,从而使施加到试样上的载荷降至最低。初始标距长度也可以进行调整或转换,使增量夹持式引伸计的应用范围更加灵活。

它们对温度也不敏感,在整个标距长度范围内的精度一致。

夹持式引伸计是用于持续应用和测量次数有限情况下的高性价比测量系统。