Clip-on extensometers

Simply reliable: Strain gauge extensometers and incremental clip-on extensometers Download- 40 mm

- -70 ... +200°C

- tensile test

- Compression test

- Metals

- Plastics

- Fiber composite materials

- Other

Clip-on extensometer: versatile and highly accurate

Clip-on extensometers are the cost-effective solution for consistent applications with a constant initial gauge length and when a limited number of measurements are taken. The high resolution of the clip-on extensometers allows even the smallest deformations to be measured during the test.

The user manually attaches the clip-on extensometer to the specimen, which is why they are referred to as clip-ons. Since they clamp directly onto the specimen, low weight and easy handling are crucial.

ZwickRoell offers clip-on extensometer based on strain gauges, and therefore they are also referred to as strain gauge extensometers, or incremental clip-on extensometers.

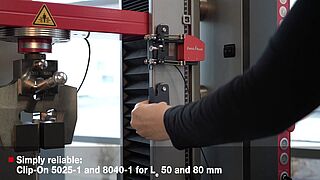

The clip-on extensometers 5025-1, 8040-1 and 7537-1

The clip-on extensometers 5025-1, 8040-1, and 7537-1 are manual clip-on extensometers based on strain gauges that can be attached to the specimen quickly and securely with one hand. These lightweight instruments are highly accurate, yet cost efficient solutions for tests with 50, 75 and 80 mm initial gauge lengths. The strain gauge displacement transducers stand out from other clip-on extensometers:

- Reproducible results through the exact and lockable setting of the initial gauge length

- Very large measurement travel distance of 50% of the initial gauge length

- High accuracy in temperature chambers through compensation of temperature-related deviations

- Optimal gripping even of round specimens with prismatic counter rollers

Clip-on extensometer: easy and accurate strain measurement for tensile tests on metals according to ISO 6892-1 / ASTM E8

The clip-on extensometers 5025-1 / 8040-1 are easily clipped on the specimen using one hand. The typical gauge lengths specified by the metals standard are preset and the initial gauge length is applied to the specimen in a reproducible manner.

Additional advantages & features of the strain gauge clip-on extensometer

- Accuracy class 0.5 according to EN ISO 9513 up to 60% of the measurement travel

- Closed loop strain rate control to ISO 6892-1 method A1 / ASTM E8 method B

- Meets the strict requirements for determination of the tensile modulus to ISO 527-1 Annex C

- Ergonomic one-handed operation: quick and easy to attach and detach

- Excellent linearity, and therefore reliable test results

- Lightweight construction, low weight

- Practical magnetic holder which always keeps the clip-on extensometers easily accessible

Other strain gauge displacement transducers

We offer other strain gauge clip-on extensometers in various designs to suit your applications:

- for axial, transverse or biaxial measurement

- with different gauge lengths and measurement travel distances

- for one-sided or double-sided measurement, and

- for different temperature ranges.

The selected portfolio also includes specialists, such as:

- For determining the Young's modulus on metals in accordance with ISO 6892-1 Annex G, we offer strain gauge displacement transducers with measurement on both sides and separate acquisition of the signals.

- The 2501-2 biaxial strain gauge displacement transducer was designed to determine the shear modulus in the in-plane shear (IPS) and to determine the Poisson's ratio on composites, providing highly accurate results even under temperature.

digiClip – the proven, incremental clip-on extensometers from ZwickRoell

These clip-on extensometers are extremely powerful and offer advantages in terms of measuring range, accuracy and signal processing compared to strain gauge systems.

This digital system delivers uniform accuracy over the entire gauge length. The miniaturization of the incremental scale enables the compact design of the digiClip. The lightweight measuring system is positioned very close to the specimen. Thus, the loading of the specimen is minimized.

The range of application of the digiClip clip-on extensometer is expanded even further by the number of different initial gauge lengths available and through the flexible change in measurement travel that can be switched from "Tensile only" to "Tensile and compression" at extension.

Applications

- Determination of the tensile modulus on plastics and fiber-reinforced composites according to ISO 527-1/-2 /-4

- Determination of the Poisson’s ratio for plastics and composites according to ISO 527-1/-2 /-4

- Determination of the in-plane shear behavior length in ±45°-shear test (in-plane shear, IPS) on fiber-reinforced composites

- r-value determination on metals according to ASTM E517 and ISO 10113.

- Closed loop strain rate control to ISO 6892-1 method A1 / ASTM E8 method B

- Determination of the compressive strength of plastics or determining Young's modulus for compression on metals

Advantages and features

- Very high resolution and accuracy over the entire measuring range. Low weight and compact design minimize the load on the specimen.

- These measuring systems are insensitive to temperature.

- The initial gauge length is automatically locked when it is attached and unlocked when it is released.

- The initial gauge length can be adjusted or converted.

- Their low height also allows them to be used for small clamping lengths.

- Adjustable depth-stop with scales for common specimen widths helps to ensure that the clip-on extensometer is always attached centrally to the specimen.

- The clip-on extensometer includes additional knife edges for notch-sensitive specimens.

- A magnetic holder and fall protection are also included.

Clip-on extensometer FAQs

Clip-on extensometers measure strain by being attached directly onto the specimen, which is why they are referred to as clip-ons. Strictly speaking, they measure a change in displacement, which is converted into a strain value by the testing software.

As clip-on extensometers have a high resolution, they measure even the smallest deformations in the test. Clip-on extensometers are manually attached to the specimen by the user and cannot be automated.

Because clip-on extensometers are directly attached to the specimen by the user, they must be easy to handle. In addition, there are ways to minimize influence by the user, for example, by locking the initial gauge length upon attachment, so that the initial gauge length remains accurately set. This significantly increases the reproducibility of test results.

Generally, clip-on extensometers are limited to one initial gauge length, but there are variations, which allow adjustment or conversion to an alternative gauge length.

Weight is also important, since clip-on extensometers are attached directly to the specimen and should keep any influence on the specimen to a minimum.

Clip-on extensometers are used for standard applications with constant initial gauge lengths and for a limited number of tests. If this is the case, clip-on extensometers are a cost-efficient solution.

The strain gauge displacement transducer is an instrument used to measure the deformation of a material specimen under load on the basis of a strain gauge.

This also includes clip-on strain gauge extensometers, which measure on the basis of strain gauges. The strain gauge inside the displacement transducer records the mechanical deformation during the test and converts it into a measurable electrical signal. Other extensometers measure incrementally, inductively or optically - we are here to advise you.

There are also strain gauge displacement transducers that are attached on the outside of the specimen, for example for flexure tests, compression tests or component testing. More information on displacement transducers for compression, flexure and component testing can be found here.

Strain gauge clip-on extensometers, which measure on the basis of strain gauges, present high precision and resolution. This is why strain gauge clip-on extensometers measure even the smallest deformations during a test. However, temperature changes also have an influence on the measurement, especially when measuring in temperature chambers. Compensation for temperature-related deviations is therefore important.

Based on their design, the initial gauge length of strain gauge clip-on extensometers is generally not adjustable. Strain gauge clip-on extensometers with a compact, lightweight design have little influence on the specimen, even though they are placed directly on it.

With incremental clip-on extensometers, the incremental scale has been miniaturized. Due to the design, the lightweight measuring system sits very close to the specimen, which minimizes the load on to which it is subjected. The initial gauge length can also be adjusted or converted, making the range of applications for incremental clip-on extensometers more flexible.

They are also insensitive to temperature and have consistent accuracy over the entire gauge length.

Clip-on extensometers are cost-effective measuring systems for consistent applications and for a limited number of measurements.