ASTM E8 | ASTM E8M Standard Test Method for Tensile Testing of Metallic Materials

The ASTM E8 / ASTM E8M standard describes uniaxial tensile testing of metals at room temperature and the determination of characteristic values including yield strength, yield point, yield point elongation, tensile strength, strain at break and reduction of area.

The values can be used to make predictions about the strength and toughness of the material.

ASTM E8 vs. ASTM E8M Specimens & dimensions Video / running a test Test speeds & control methods Strain rate control Testing systems Other related standards FAQ's

Differences between ASTM E8 and ASTM E8M

Strictly speaking, this ASTM standard includes two standards, and therefore ASTM E8 must be differentiated from ASTM E8M. While ASTM E8 refers to inch and pound units of measurement, ASTM E8M uses SI units. This leads to the fact that characteristic values determined with one system of units are not exactly equal to those determined with the other system of units. In practice however, this usually does not present a problem, because there is no change between the units when determining and comparing characteristic values.

Within this context, it is however important to note that the initial gauge length for the determination of strain in ASTM E8 refers to 4D, or four times the diameter of the round specimens, while in ASTM E8M it refers to 5D, or five times the diameter of the round specimens. A mix-up or failure to observe this difference can lead to characteristic values that are no longer comparable.

ASTM E8 and ASTM E8M go into detail about the testing machine and the type of specimen grips and provide guidance on the proper use of specimen grips.

ASTM E8 specimens and dimensions

Important information is provided for specimen preparation, to ensure that the machining process and the subsequent specimen preparation do not influence the material, since this could in turn affect the results of the tensile test.

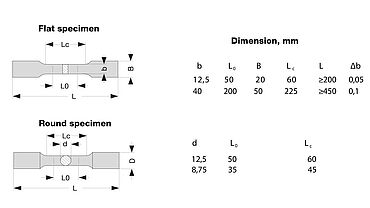

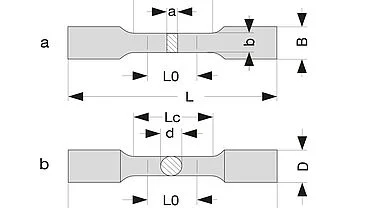

There can be a wide range of shapes for tensile specimens. ASTM E8/ASTM E8M lists standard flat specimens for sheet metals and thin sheet metals, for tubular products, for special specimen grips, and standard round specimens for other metal products, and specifies the corresponding initial gauge lengths to which all strain values refer. With a few exceptions, all dimensions that are needed for specimen preparation are specified, or else minimum dimensions are indicated.

Both the specimen shape and the specimen machining process are defined in the ASTM E8 test standard. Specimens must be prepared in such a way that the material properties are not influenced. All areas that were strain hardened through cutting or punching during the specimen machining process must be processed accordingly, if they have an effect on the specimen properties.

Products with a constant cross section (profiles, bars, wires, etc.) and cast specimens

(e.g. cast iron, nonferrous alloys) can be tested without processing. Preferred specimen shapes according to ASTM E8 are flat specimens (shouldered-end) and round specimens.

ASTM E8 test speeds and control methods

Particular focus is on the test speed. ASTM E8 and ASTM E8M support five different ways of specifying test speeds. They are designated as

- (a) Specimen strain rate,

- (b) Specimen stress rate,

- (c) Crosshead speed,

- (d) The elapsed time for completing part or all of the test, or

- (e) Free-running crosshead speed (rate of movement of the crosshead of the testing machine when not under load).

For determination of the so called yield properties, that is the yield strength, yield point elongation, and offset yield, in general all characteristic values related to the change of material behavior from elastic to plastic, it is important to define a suitable control of the test speed. Because in the case of metallic materials, these characteristic values can be significantly dependent on the actual test speed, and therefore the test speeds must be maintained within specified tolerances. ASTM E8 and ASTM E8M take this into account with three different control methods. They are designated as Method A, B and C.

All figures for the three methods described below are to be used unless product standards or standards for special applications specify other values.

If determination of the yield strength and offset yield have been completed (or do not have to be determined) and a specimen elongation of more than 5% is expected, the test speed can be increased to 0.05 up to 0.5 in./in./min (oder mm/mm/min*)). This specification refers to either the initial gauge length of the measuring extensometer or the initial parallel length of the specimen. The test speed is therefore indicated as a strain rate. At this test speed, all other characteristic values for the tensile test are then determined according to ASTM E8/ASTM E8M.

Comparing the test speed control methods according to ASTM E8

Recommended method |

|

|

|

|

|

|

|

|

Method A: stress speed

Method A is based on the increase in tensile stress during load application.

- In the linear elastic part of the tensile test, that is at the very beginning of the test, the rate of stress application must be between 1.15 and 11.5 MPa/sec (this corresponds to 10000 and 100000 psi/min).

- However, it is clearly stated in ASTM E8 and ASTM E8M that these specifications and method do not imply that the stress increase should be held constant up to the point of plastic behavior or that closed loop control of the force increase may be applied beyond the linear elastic range.

Method C: crosshead speed

Method C is based on constant speed of the crosshead.

- The crosshead speed shall be set and kept constant so that the initial parallel length of the specimen undergoes an elongation of 0.015 ± 0.003 in./in./min or mm/mm/min.

- This method is recommended if the material does not deform continuously.

Method B: closed loop strain rate

Method B is based on the control of the strain speed or strain rate (strain rate control) during the load application.

- The testing machine keeps the closed loop strain rate constant by using an extensometer to continuously provide strain values that are used to calculate the precise strain rate.

- The standard specifies a strain rate of 0.015 ± 0.006 in./in./min or mm/mm/min, which corresponds to a tolerance of 40% when setting the strain rate.

With our testXpert testing software, the strain rate is always traceable.

- The red line (1) shows the ASTM E8 defined tolerance range (40% of the set speed).

- The green dashed line represents the narrower tolerance range of 5%, which is the benchmark used by ZwickRoell testing systems to be on the safe side in the event of unforeseen events. Good strain rate control is characterized by (2) low inlet fluctuations and (3) stable speed control. An important requirement for this is an adaptive controller.

Why closed loop strain rate is recommended

Strain rate control increases the reliability of test results and ensures reproducibility. The characteristic values of metallic materials are largely dependent on the strain rate. Usually, the higher the strain rate, the higher the strength values. Alloys and other product features also influence the strain rate dependence.

Special benefits are provided by closed loop strain rate control for which an adaptive controller is used to automatically maintain the correct strain speed:

- Time savings: the system automatically sets the correct strain rate, without user intervention.

- Simply reliable: this also eliminates errors when setting parameters

- Precision: an adaptive controller prevents overshooting of strain rates, keeping them constant and well within the tolerance range so that the strain rate also remains within tolerance limits in case of unforeseen events.

This method requires a control-technology-equipped testing system, which however significantly simplifies the test operation.

ASTM E8 with testXpert testing software – efficient and reliable testing

With testXpert, you increase efficiency for tests to ASTM E8. And testXpert delivers reliable test results, the foundation for decisions you can count on.

- Regardless of the method you select, all the parameters specified by ASTM E8 are included in test program with 100% standard-compliance. In a preconfigured layout, you see the true achieved strain rate within the tolerances specified by the standard.

- Don’t spend unnecessary time on pre-tests and manual calculations for the strain rates according to ASTM E8. testXpert takes on automatic setting of all control parameters. Target positions and strain values are approached with pinpoint accuracy. Changes in specimen properties are compensated on line.

- testXpert ensures repeatable test results through identical test conditions via a predefined machine configuration.

- For reproducible test results, operator influence is reduced to a minimum, for example through our user management feature.

Frequently asked questions regarding ASTM E8

The ASTM E8 / ASTM E8M standard describes uniaxial tensile testing of metals at room temperature and the determination of characteristic values including yield strength, yield point, yield point elongation, tensile strength, strain at break and reduction of area. The values can be used to make predictions about the strength and toughness of the material.

While ASTM E8 refers to units of measurement “inch” and “pound”, ASTM E8M uses SI units. Because of this, values determined with one system of units are not exactly equal to those determined with the other system of units. The initial gauge length for the determination of strain in ASTM E8 refers to 4D, or four times the diameter of the round specimens, while in ASTM E8M it refers to 5D, or five times the diameter of the round specimens. A mix-up or failure to observe this difference can lead to characteristic values that are no longer comparable.

The ASTM E8 / ASTM E8M standard describes uniaxial tensile testing of metals at room temperature and the determination of characteristic values including yield strength, yield point, yield point elongation, tensile strength, strain at break and reduction of area. The values can be used to make predictions about the strength and toughness of the material.

Other common ASTM standards for tensile tests are ASTM D638 for plastics, ASTM D412 for rubber and elastomers and ASTM D3039 for fiber composites