Automated Test Systems

Automated test systems assume the specimen handling task in the testing lab and carry out repeatable and reproducible tests according to standard requirements. Robot-based quality assurance testing ensures compliance with demanding test and system-operation requirements. Automated materials testing is especially useful for high throughput rates.

ZwickRoell offers various test systems for automated materials testing:

For metals For plastics For medical applications For textiles & film For components

Additional information on our automated testing systems:

Advantages Manual tests Automation software Why automate? ROI Calculator

Automated materials testing with ZwickRoell

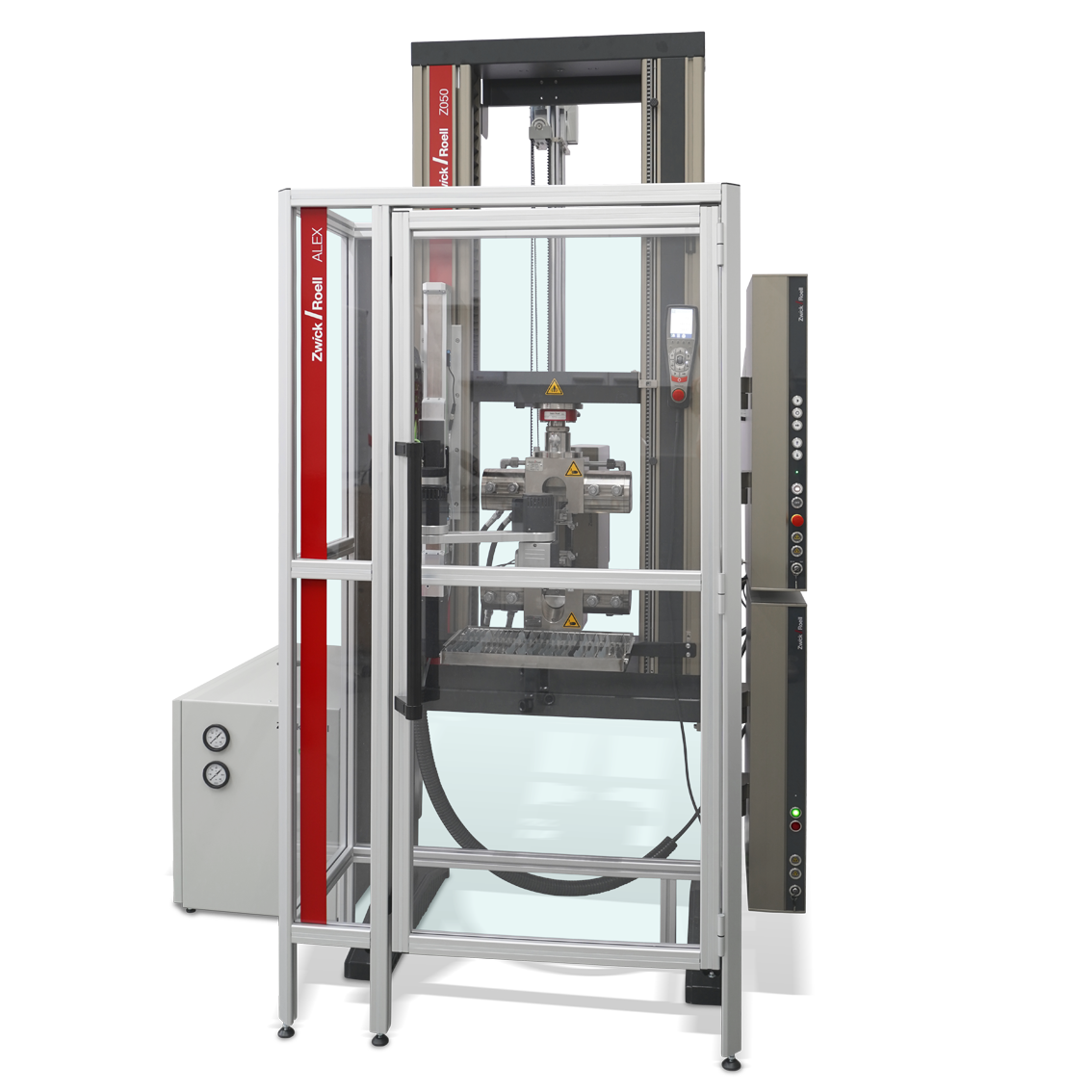

With ZwickRoell automation, specimens awaiting testing are manually sorted into magazines. From this point on, the testing system assumes the entire process from specimen transport, to automated testing and sorting of the specimen remains for verification, if necessary. This relieves qualified laboratory staff of routine activities, leaving them available for more demanding tasks.

Depending on requirements, additional measuring devices can be integrated into this sequence, particularly ZwickRoell’s cross-section measuring device with four independent, automatically applied measuring transducers for precise determination of the cross-sectional area.

Graphic visualizations transmit system status in real time to mobile devices such as tablet PCs. This allows full process control via all current browser programs. Visualization increases the efficiency of the robotic testing system by reducing idle time.

The modular design of the automated testing system also allows you to run manual tests on the machine as required.

Automated materials testing: metals

Manufacturers of steel and metals must test their products for quality assurance, typically through tensile tests, among others. Robot-based quality assurance testing is typically used for high specimen throughput rates. ZwickRoell offers various testing systems for automated tensile tests on anything from sheet metals to heavy plate metals.

For sheet metals, in addition to determining characteristic values such as yield strength, tensile strength or offset yield, the r-value and n-value are also commonly measured. Prior to the tensile test, the robotic testing system measures the thickness and width of the specimen.

One advantage in the case of heavy plate in particular, is that the testing system takes over the task of handling the heavy specimens. Using a robotic testing system also eliminates hazards created by rough edges or falling specimens.

Our robotic testing system software solution consists of the higher-level autoEdition automation software and our testXpert testing software. While autoEdition assumes data management and control as well as process visualization, testXpert manages the results of the automated tensile test.

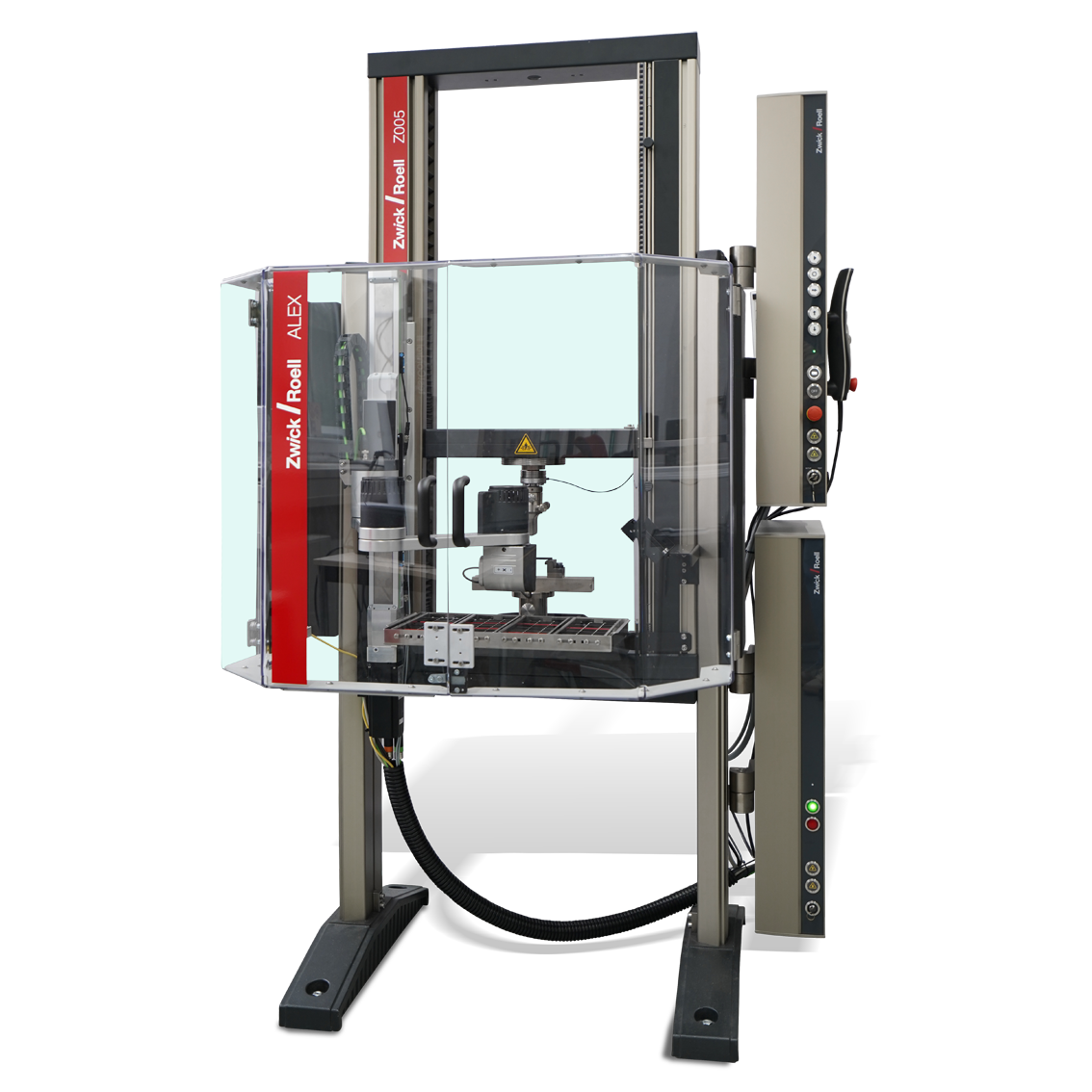

| ALEX | roboTest L | roboTest N | roboTest R | roboTest P | roboTest I | |

|---|---|---|---|---|---|---|

|  |  |  |  |  | |

| ALEX | roboTest L | roboTest N | roboTest R | roboTest P | roboTest I | |

| Applications |

|

|

|

|

|

|

| Type of test | Tensile | Tensile | Tensile | Tensile | Tensile | Impact (Charpy) |

| Number of specimens | Up to 30 specimens | Up to 160 specimens | Up to 80 specimens | Up to 400 specimens | Up to 300 specimens | 10 specimens (tempered); 90 specimens (untempered) |

| Specimen weight (max.) | 250 g | 1 kg | 500 g | 30 kg | 20 kg | - |

| Force/energy (max.) | 100 kN | 250 kN | 250 kN | 2,500 kN | 2,500 kN | 750 J |

| Test task | Simple | Simple | Simple | Complex | Complex | Simple |

| Equipment options and accessories | ||||||

| 2D-code/barcode scanner | • | • | • | • | • | • |

| Cross-section measurement | • | • | • | • | • | • |

| Multiple testing machines | - | - | • | • | • | - |

| Hardness measurement | - | - | • | • | • | - |

| Roughness measurement | - | - | • | • | • | - |

For hardness or roughness measurement only (without testing machine), the roboTest N can be used to feed the specimens into the hardness tester of roughness measuring device.

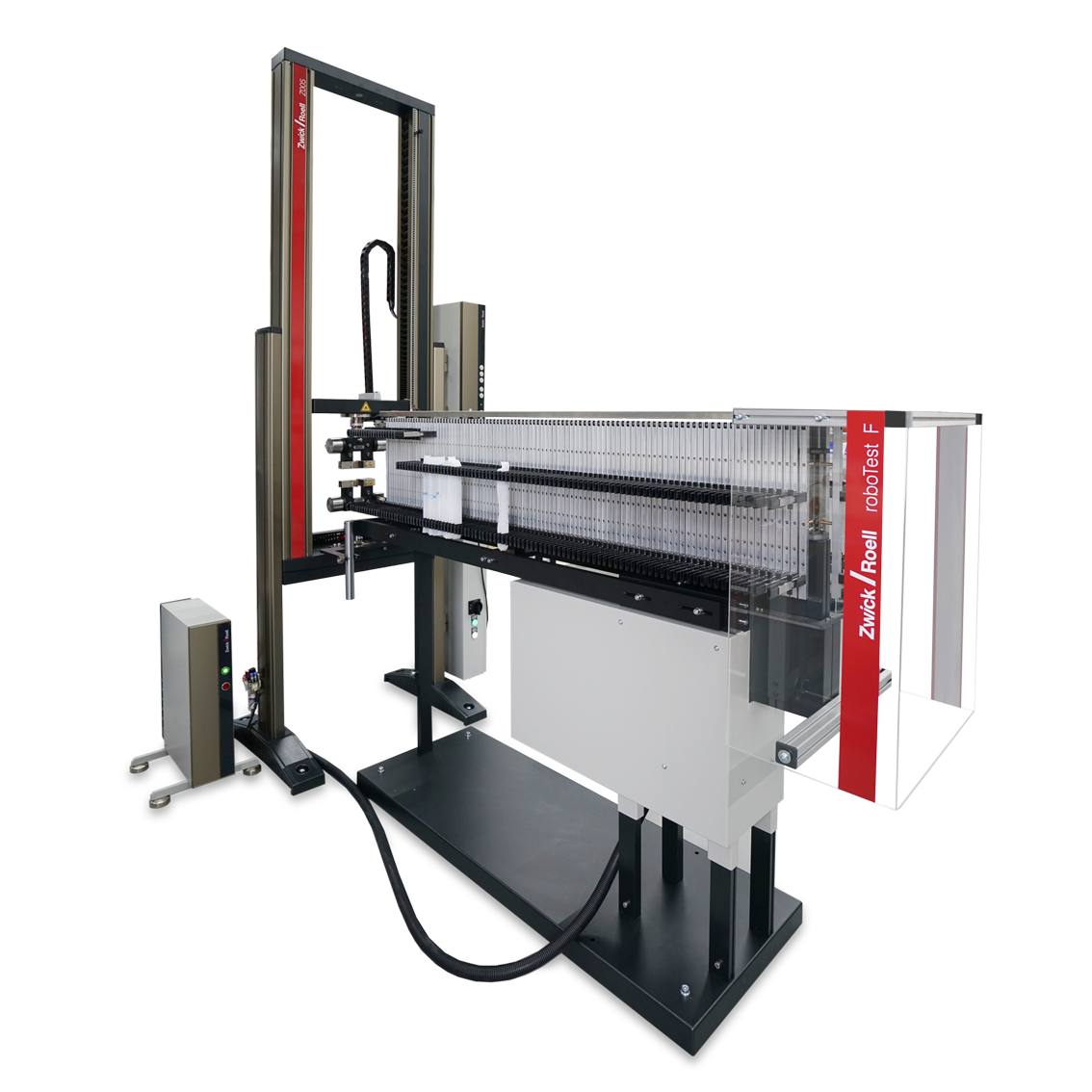

- Aluminum foil can be automatically tested with the roboTest F. A clamping system securely holds the specimen and properly positions it in the specimen grips.

- For smaller specimen series with heavy specimens, the roboTest C is the ideal robotic testing system.

Automated materials testing: plastics

Thermoplastics and thermosetting molding materials, polymer foams, elastomers and composites are tested in terms of quality assurance and for research and development purposes. When it comes to large volumes of specimens in particular, these tests tie up a lot of personnel.

A testing system for automated tests on plastics relieves qualified laboratory personnel of these routine tasks, allowing them to take on more complex tasks, such as resulting data interpretation and assessment, evaluation of the new materials or other research activities.

Small specimen dimensions, or—especially in the case of elastomers—somewhat unstable specimens are often more difficult to grip. By using the robotic testing system to position the specimen, user safety is increased and operator influence on the specimen results is minimized, making test results more reproducible and statistically more reliable.

Our robotic testing system software solution consists of the higher-level autoEdition automation software and our testXpert testing software. While autoEdition assumes data management and control as well as process visualization, testXpert manages the results of the automated tensile test.

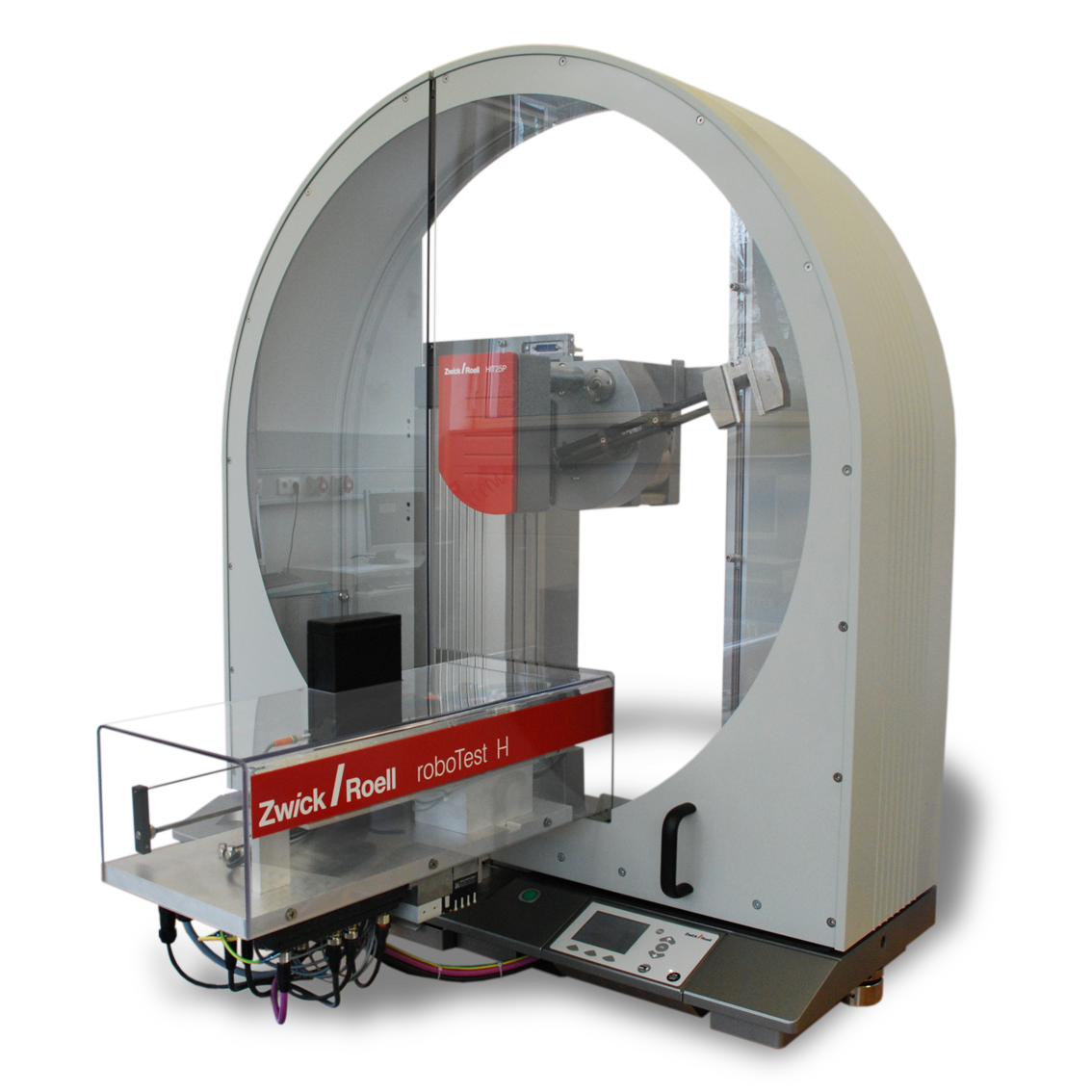

| ALEX | roboTest N | roboTest L | roboTest R | roboTest F | roboTest H | |

|---|---|---|---|---|---|---|

|  |  |  |  |  | |

| ALEX | roboTest N | roboTest L | roboTest R | roboTest F | roboTest H | |

| Applications |

|

|

|

|

|

|

| Type of test |

|

|

|

|

|

|

| Number of specimens (max.) | 60 Specimens | 80 Specimens | 450 Specimens | 400 Specimens | 200 Specimens | 80 Specimens |

| Test task | Simple | Simple | Simple | Complex | Simple | Simple |

| Equipment options and accessories | ||||||

| 2D-code/barcode scanner | • | • | • | • | • | • |

| Cross-section measurement | • | • | • | • | • | |

| Scale | - | • | • | • | - | - |

| Multiple testing machines | - | - | - | • | - | - |

| Hardness measurement | - | - | - | • | - | - |

| Temperature chamber | - | • | - | • | - | Specimens are pre-tempered externally |

- The roboTest I can be used for impact tests (Charpy or Izod) with active specimen tempering. Here, plastic can be tested in a temperature range of -80 °C to +100 °C.

Automated materials testing: medical industry

Especially in the medical and pharmaceutical industry, the safety requirements for products are more pronounced than in most other industries. The test sequence for products such as autoinjectors, pen injectors, Luer lock connections or syringes is precisely defined in industry standards. A test often consists of different steps and can teak several minutes to complete.

Automated test systems especially support quality testing by relieving laboratory personnel. The robotic testing system assumes performance of the test, which leaves employees free focus to on more complex testing and analysis tasks.

By eliminating user influences, automated testing of medical applications is reliable and repeatable.

Our robotic testing system software solution consists of the higher-level autoEdition automation software and our testXpert testing software. While autoEdition assumes data management and control as well as process visualization, testXpert manages the results of the automated tensile test.

| roboTest N | roboTest L | roboTest R | |

|---|---|---|---|

|  |  | |

| roboTest N | roboTest L | roboTest R | |

| Applications |

|

|

|

| Type of test |

|

|

|

| Number of specimens (max.) | 40 Specimens | 80 Specimens | 200 Specimens |

| Test task | Simple | Simple | Complex |

| Equipment options and accessories | |||

| 2D-code/barcode scanner | • | • | • |

| Cross-section measurement | • | • | • |

| Multiple testing machines | - | - | • |

| DQ/IQ/OQ | • | • | • |

Automated materials testing: films, foils & textiles

Quality assurance is imperative in the manufacturing of plastic film and aluminum foil. Because of the lack of stability of film and foil materials and textiles, automated tests present a particular challenge. In order to make materials testing in the manufacturing process efficient and safe, ZwickRoell developed a robotic testing systems specifically for these types of specimens.

With the special clamping system of the roboTest F, textiles can be precisely gripped in the magazine, securely positioned in the testing machine, and then automatically tested.

Automated materials testing: components & special automations

The robotic testing systems can be used for tensile tests, compression tests or function tests on components . Robotic testing systems can also be used for customized applications, such as for testing of iron ore pellets, testing in the hot cell, roughness testing or hardness testing.

Due to the modular design of the robotic testing systems, the required tests can be carried out efficiently and reproducibly. Standard components can be used to build customized solutions.

Advantages of automation

ZwickRoell has an extremely large range of automated testing systems with a wide variety of features to suit all applications.

- Thanks to parallel processing of specimens, ZwickRoell automated systems deliver test results significantly faster than automated systems with a conventional software architecture.

- Graphic visualization transmits the system status in real time to mobile devices such as iPads.

- Eliminating operator influence delivers high reproducibility of the test results.

- Qualified laboratory staff are relieved of routine activities, making them available for more complex tasks.

- Unsupervised 24/7 system operation ensures consistently high efficiency in the testing laboratory.

- Main objectives of robot based testing systems: improve test quality, increase productivity, maintain flexibility.

Amortization of an automated testing system

Your investment in a materials testing machine with automated specimen feeding is an investment in the future of your testing lab. Many users are not sure at what point a robotic testing system becomes a worthwhile investment.

In our experience, we haver found that an automated testing system typically pays for itself within two to three years. This is not just dependent on the number of specimens tested per day, but other factors including material composition and the complexity of the test must also be considered.

You can use our ROI calculator to help determine if an automated testing systems makes sense for you. We would be happy to send you more information for a detailed and comprehensive analysis of your data.

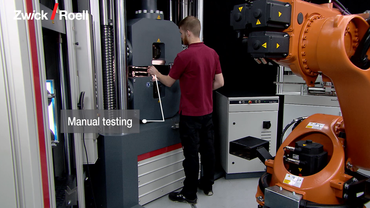

Manual testing with automated testing systems

With an automated testing system, the operator can also perform manual tests as needed.

For manual specimen testing, the robot is moved to a safe parked position or the testing system is uncoupled from the machine. The operator manually inserts the specimen and starts the test from the testXpert screen.