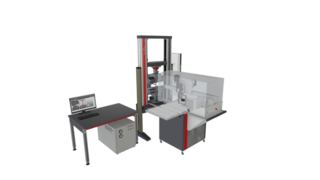

Robotic Testing System roboTest L

The automated testing machine for tensile tests and flexure tests Download- Plastics

- Metals

- Composites

- Rubber

- Medical

- Tensile

- Flexure

- Specimens up to 1 kg

- ISO 6892

- ASTM E8

- JIS Z2201

- ISO 527-2

- ASTM D790

- ISO 178

What is a roboTest L?

The roboTest L is a fully automated testing machine for metals and plastics. It can be used for tensile tests, flexure tests or tear growth tests (elastomers).

Depending on the specimen dimensions and specimen surface, up to 480 specimens can be tested autonomously.

The specimens to be tested are placed in a movable magazine table (X-axis). The gripper (Y-axis) removes the specimens from the magazine and conveys them to the testing machine where the fully automated test is run. Optional components including an ID scanner, cross-section measuring device, HOST connection, accept/reject feature, disposal gripper, and status indicator, complete the system.

Manual tests can be performed as required by moving the specimen feeding system out of the way.

Video: Automated Testing Machines (Standard Configuration)

Other roboTest L application examples

Advantages of the roboTest L

- Operator influences (hand temperature/moisture, off-center or angled specimen insertion, etc.) are eliminated resulting in high test-result reproducibility.

- Qualified laboratory staff are relieved of routine activities, allowing them to focus on more complex tasks.

- The automated testing machine can be used during idle times (lunch breaks and night shifts), which increases its full capacity and produces faster results.

- The testing system reduces the testing costs per specimen and typically pays for itself within one to two years.

- The system supports secure documentation and statistical long-term monitoring.

- Non-contact measurement of the extension and change in width with the videoXtens L (optional): The extension is measured on both sides of the specimen, since for a cold strip, for example, the material can flow unevenly on the two sides.

Components and accessories

autoEdition3 automation software

The autoEdition3 automation software is at the core of the robotic testing system. The software controls, regulates and monitors all automated processes, components and devices.

In combination with our testXpert testing software the autoEdition3 automation software delivers traceable and tamper-proof results. Immediately upon starting autoEdition3, the user experiences the benefits of intuitive operation from a look and feel that is consistent with the testXpert user interface.

SmartWizard configuration interface

A SmartWizard software assistant option is available for the roboTest L standard package for tensile tests on metals, which allows the operator to independently adapt the robotic testing system to changing specimen shapes or test sequences.

It offers the freedom and flexibility you need to be successful in a world of fast and continuously evolving requirements.

Your testing system is ready to learn!