Compression Tests and Compression Testing Machines

A Compression test uses compression testing machines to determine material behavior under constantly increasing compressive loading. Compression tests examine the safety, durability, and integrity of materials and components. Typical applications include compression tests on plastic tubes and plastic pipes, compression tests on flexible cellular foam material, compression/crush tests on paper and cardboard, compression spring testing in the metals industry, compression tests in the medical/pharmaceutical field including compression testing of medical implants, stents, syringes or medical packaging, compression and notched compression tests on composites.

A compression testing machine is a universal testing machine (UTM) equipped with application-specific compression test tools or compression platens. The tools are selected and installed in the machine based on criteria such as test type, specimen material and dimensions, test temperature and maximum force values expected.

Compression test definition Compression testing machines Accessories for compression tests Videos

We would also be happy to inform you about our test solutions for standardized compression tests according to ISO, ASTM and others in the various industries:

Overview of standards for compression tests

Definition of compression test

- Compression tests are performed to characterize the behavior of a material under compressive loading.

- During the test, pressure is applied to a specimen using compression platens or special tools mounted on a universal testing machine to determine various properties of the material being tested.

- The test data delivers results in the form of a stress-strain diagram that displays among other things, the elastic limit, the proportionality limit, the yield point and, in some cases, the compressive strength.

A compression test, in which the specimen is pressed together is basically the opposite of the tensile test, which pulls the specimen apart. Tests can be performed on machined material specimens or on full-size or scale models of actual components. Common types of compression tests include the top-load (crush) test, flexure (bend) test and spring test.

Which standards are used when performing compression tests?

Compression tests examine the safety, durability, and integrity of a wide range of materials and components. An excerpt of important ISO standards and ASTM standards for compression tests can be found in the following table.

We are also ready to discuss your individual testing requirements.

Important standardized compression tests

| Short description | Standards |

|---|---|

| Composites & plastics | Compression test (end loading) |

|

| Cardboard | Corrugated board | Flat crush test (FCT) |

|

| Cardboard | Corrugated board | Edge crush test (ECT) |

|

| Cardboard | Corrugated board | Box crush and stacking crush test |

|

| Plastics | Pipes | Ring stiffness / ring flexibility |

|

| Compression test with shear loading |

|

| Composites | Compression test (combined loading) |

|

| Composites| Notched compression test (OHC, FHC) |

|

| Paper | Flat crush resistance / corrugated medium test (CMT) |

|

| Paper & cardboard | Ring crush test (RCT) |

|

| Paper & cardboard | Compressive strength / short clamping test (SCT) |

|

| Plastics | Flexible foam | Compression stress value |

|

| Plastics | Flexible foam | Indentation hardness |

|

| Composites | Compression after impact (CAI) |

|

| Medical | Stents | Radial compression test |

|

| Medical | Syringes | Plunger glide force |

|

| Plastics | Flexible foam | Constant-load pounding test |

|

| Plastics | Rigid foam | Compression test |

|

Compression testing machines

A compression testing machine is a universal testing machine (UTM) specially configured to determine a material’s strength and deformation behavior under compressive (pressing) load. A typical machine for compression tests consists of a load cell, a crosshead(s), compression test tools, electronics, and a drive system. It is controlled by testing software that defines machine and safety settings and stores test parameters specified by ASTM standards and ISO standards. To choose the right compression test equipment, it is important to consider the material to be tested and the standard(s) that must be followed. Measuring the force until a specified load or distance has been reached, or until the specimen cracks or breaks, helps designers and manufacturers predict how a material will perform when implemented for its intended purpose.

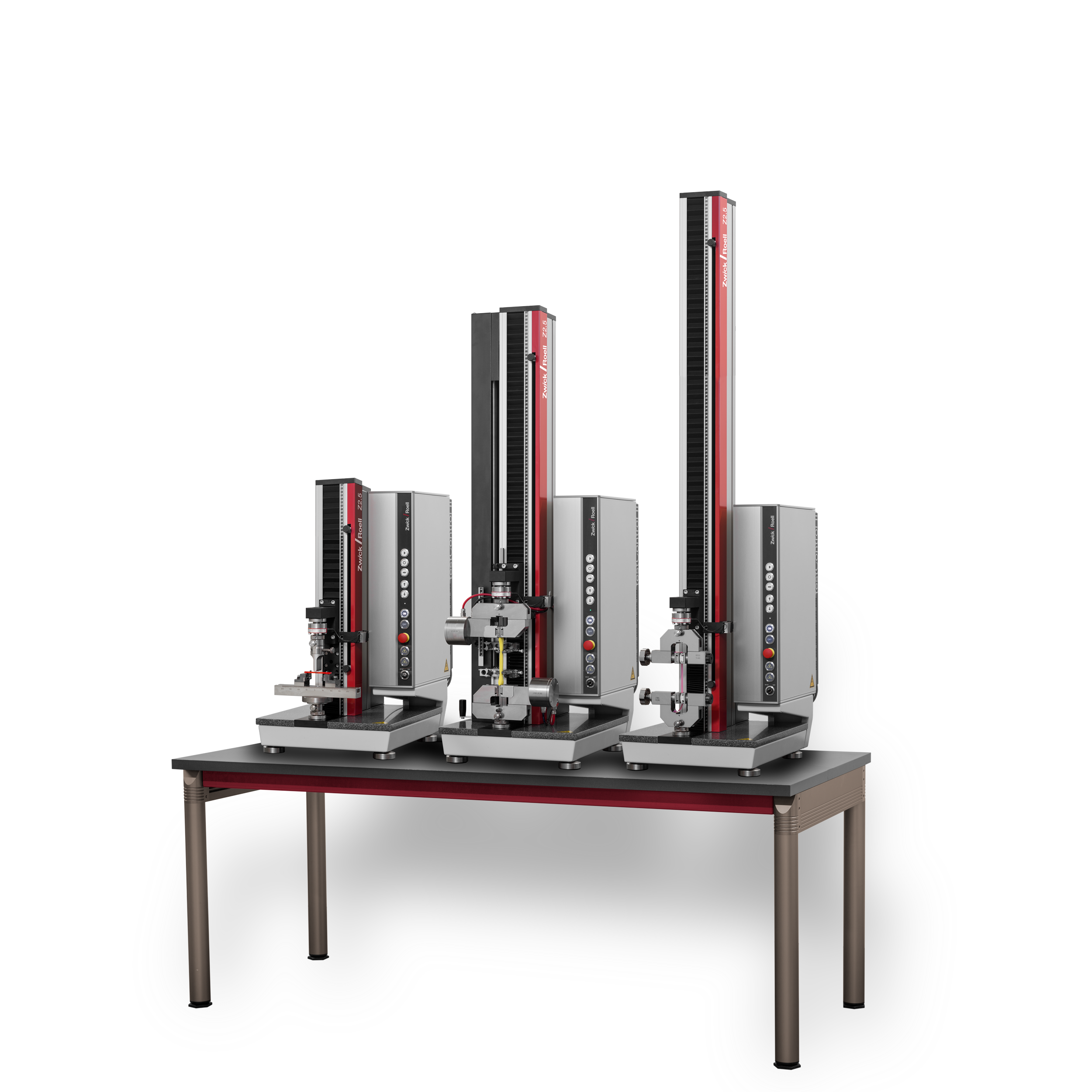

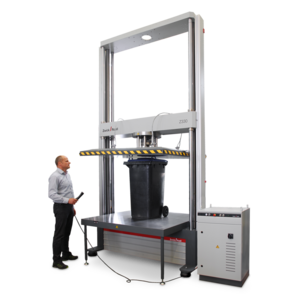

ZwickRoell compression testing machines, including the zwickiLine, ProLine, AllroundLine, and drop weight testers, are specifically designed to meet customer requirements based on testing capacity, types of material, applications, and industry standards. In addition to overall system safety and reliability, ZwickRoell designs and builds every part of our machines with a focus on providing:

- A high level of flexibility through ease of operation

- Simple adaptations to customer- and standard-specific requirements

- Future-proof expansion capabilities to grow with your needs

Comparison of ZwickRoell compression testing machines

| Model | zwickiLine | ProLine | AllroundLine | Drop weight testers | High-capacity machines |

|  |  |  |  | |

| Type | Electromechanical table-top testing machine | Electromechanical table-top testing machine | Electromechanical table-top testing machine (5 kN – 150 kN) Floor testing machine (50 kN – 250 kN) | Drop weight tester | Electromechanical |

| Load range | 0.5 kN – 5 kN | 5 kN – 100 kN | 5 kN – 250 kN | Up to 2,000 J | 330 kN - 2,500 kN |

| Application examples for compression tests, indentation tests, puncture tests |

|

|

|

|

|

You can find more information on these and other application examples in the sections that follow.

Compression platens and test tools for compression testing

The compression tools used are in direct contact with the materials to be tested. Therefore they have to be precisely aligned and adapted to the respective applications and requirements. A wide variety of compression test kits are available for all types of tests. These compression tools can be individually adapted to the specific application according to the respective requirements.

Compression test kits normally consist of tow primary components, the upper and lower test tool.compression tool. To use the test tools for as many different tests as possible and with a high level of flexibility, we assembled a comprehensive, interchangeable and combinable tool portfolio.

The different requirements for the individual compression fixtures are essentially the result of:

- The specifications defined in international standards

- The large number of different specimens, materials and components

- The wide variety of specimen shapes and dimensions

- The many different types of environmental conditions (temperature, humidity, ...)

Below you will find an excerpt of our comprehensive compression test tool portfolio, which is tailored to the requirements of the various industries we serve.

Compression platens Plastics/foam Composites Medical/pharma Paper/Cardboard

Compression platens

Compression platens must be selected with the specific test criteria in accordance with the application in question. Knowing the specimen dimensions and the maximum forces to be expected for the test is critical.

Compression platens can be used for tests up to 250 kN. A distinction is made between round and rectangular platens. All compression platens can be used in a temperature range of -70 ... +250°C. The different dimensions of the compression platens are stated as a leading selection criterion for each individual platen.

Specimen sizes required at defined test loads:

| Test load | Min. specimen surface area required with permissible surface pressure of | Typical sizes: Square specimen at | Typical sizes: Round specimen at | |||

| 300 N/mm2 | 90 N/mm2 | 300 N/mm2 | 90 N/mm2 | 300 N/mm2 | 90 N/mm2 | |

| 10 kN | 30 mm2 | 110 mm2 | Approx. 6 mm | Approx. 11 mm | Approx. Ø 7 mm | Approx. Ø 12 mm |

| 20 kN | 70 mm2 | 220 mm2 | Approx. 8 mm | Approx. 15 mm | Approx. Ø 9 mm | Approx. Ø 17 mm |

| 50 kN | 170 mm2 | 550 mm2 | Approx. 13 mm | Approx. 24 mm | Approx. Ø 15 mm | Approx. Ø 27 mm |

| 100 kN | 330 mm2 | 1100 mm2 | Approx. 18 mm | Approx. 34 mm | Approx. Ø 20 mm | Approx. Ø 36 mm |

| 150 kN | 500 mm2 | 1700 mm2 | Approx. 23 mm | Approx. 41 mm | Approx. Ø 25 mm | Approx. Ø 46 mm |

| 250 kN | 830 mm2 | 2800 mm2 | Approx. 29 mm | Approx. 53 mm | Approx. Ø 33 mm | Approx. Ø 60 mm |

Videos on compression tests performed in various applications

Calibrating your compression testing machine

ZwickRoell is your first stop for materials testing machine services. With a worldwide service network, hundreds of service employees, and numerous international accreditations according to EN ISO/IEC 17025 for our calibration laboratories, you are in good hands with ZwickRoell.

ZwickRoell has multiple accreditations. Our calibrations are verifiably independent, efficient and precise.

More information about ZwickRoell calibrations:

Frequently asked questions

A compression testing machine is a universal testing machine (UTM) specially configured to determine a material’s strength and deformation behavior under compressive (pressing) load.

The specimen or component is placed between two compression platens installed in the materials testing machine. The machine crossheads move the platens together with a specified force, speed and/or crosshead travel distance. The required values are measured and recorded.