Extensometers

An extensometer is a strain measurement device used to measure the extension of a specimen under load. Extension measurement is one of ZwickRoell’s core competencies.

Overview Contact extensometers Optical extensometers Selection criteria Request a consultation

There are essentially two main categories of extensometers: contact and non-contact or optical extensometers. Contact extensometers can be further categorized into clip-on and sensor arm extensometers. Non-contact, or optical extensometers include the video extensometer and laser extensometer.

| Clip-on extensometers | Sensor arm extensometers | Video extensometers | Laser extensometers | |

|---|---|---|---|---|

| Application | Cost-effective solution for standard applications with set initial gauge length and low specimen throughput | Easily adaptable for different testing applications | Easily adaptable for different testing applications Camera-based: the images can be used for additional evaluation purposes, such as 2D DIC | Special technology for measurement under high temperature |

| Specimen material | Inherently stiff specimens | All | All; including highly sensitive specimens and specimens with high break energy | Metals, ceramics, refractory materials, graphite, glass |

| Temperature | Up to max. 200 °C | Up to max. 360 °C | Up to max. 360 °C | Up to max. 2000 °C |

| Operation | Manual | Configurable from manual to automatic | Automatic: no operator influence, high reproducibility of test results | Automatic: no operator influence, high reproducibility of test results |

What is an extensometer?

An extensometer is a strain measurement device used to measure the extension of a material under load.

- The extension of a material is a physical deformation that occurs when it is subjected to a load such as the pulling force associated with tensile testing. In addition to strain caused by tensile loads, extensometers also help determine compressive deformation or deflection under different types of load applications, including cyclic tests (incl. fatigue tests), compression tests and flexure tests.

- Extensometers measure strain directly on the specimen. This eliminates measurement influences from other testing components and increases accuracy.

- Strain measurement is required in the determination of characteristic values of a material. The tensile modulus, Young's modulus, yield point, strain at break, r-value and Poisson’s ratio are typical values determined with an extensometer. This information is essential when comparing materials, and helps manufacturers determine whether they are able to withstand the loads to which they are subjected when used for their intended purpose.

- Extensometers are used in a wide variety of industries and an even wider range of materials. Examples include metals, plastics, fiber-reinforced composites, elastomers, films, textiles, ropes, paper and wood.

Sensor arm extensometers

Sensor arm extensometers are attached directly to the specimen via knife edges mounted on the sensor arms. Strain is measured through evaluation of the change in angle or travel distance of the sensor arms. Sensor arm extensometer technology is proven and easy to understand. These extensometers offer a high level of modularity, which allows them to be easily adapted and handled for different test tasks: From cost-efficient, manual extensometers to fully automatic systems, completely without operator influence and with maximum reproducibility of test results.

Clip-on extensometers

Clip-on extensometers are a cost-effective solution for standard test tasks with low specimen throughput. They are attached directly to the specimen. The measurement value transmission from the specimen to the sensor is short and rigid, resulting in high measurement accuracy.

These extensometers, however, lack in flexibility: From a design perspective, most of them have a set initial gauge length and limited travel distance.

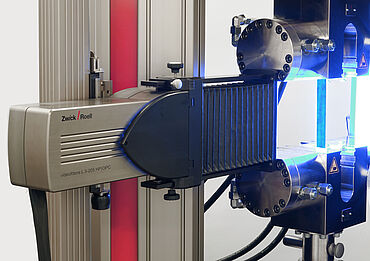

Optical / non-contact extensometers

The videoXtens and laserXtens optical extensometers are camera-based and therefore contactless. They therefore have no influence on the determination of the material characteristics. An additional advantage provided by non-contact strain gauges is that they can also be used on critical specimens up to the point of break without the risk of damage. The initial gauge length of optical extensometers is indicated by gauge marks. ZwickRoell video and laser extensometers can also be used without the need to manually add gauge marks.

The optical lightXtens extensometer operates on the basis of light diodes. This extensometer is specially designed for fully automatic measurement on highly ductile materials (elastomers, ropes, foils) or specimens with a large initial gauge length (steel ropes and stranded wire)

Why choose an extensometer from ZwickRoell?

- Extensometers are one of our core competencies resulting from decades of application technology experience.

- Our extensometers are developed and manufactured in-house alongside our other testing components, guaranteeing full testing system compatibility.

- ZwickRoell extensometers are designed to exceed standard requirements, since extensometer accuracy is essential for reproducible and reliable test results.

Selection criteria

Almost all tensile testing standards such as ASTM and ISO require strain measurement. The best suited extensometer for an application depends on the requirements set forth by the standard as well as the material properties of the specimen.

Determination of the ideal extensometer is based on six main criteria. These include properties that must be met, such as extensometer accuracy, resolution, measurement range, required measured values and the test temperature at which the extensometer will be used. But the key added value is provided by features such as easy handling, reduced learning curve, the scope of functionality, cost per test and further information provided by added options.