Purpose of the test

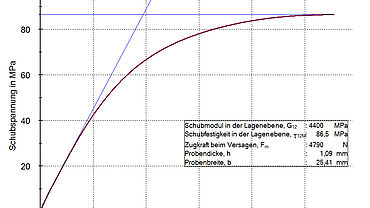

- In-plane shear can be produced by performing a tensile or compression test at ±45° to the fiber direction. The specimens are cut from plates at 45° to the fiber direction.

- In addition to tensile and compression tests used to determine the stress, strain, and modulus values in the principle stress direction, measurement of in-plane shear characteristics play a significant role in the characterization of composites.

- Measured values are in-plane strain γ 12, in-plane stress τ 12, and shear modulus G 12.

- Since this method has strict requirements for specimen preparation, and can be carried out on a testing machine like a tensile test, it can be used for material characterization in research and development as well as in mass testing for quality assurance purposes.

The test method

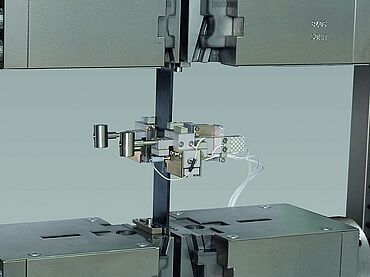

Shear deformation occurs along the fiber direction, since fibers with an angle less than 45° end on the side edge of the specimen in a tensile specimen. This shear deformation can be determined using two strain gauges at 0° and 90°, or using a biaxial extensometer.

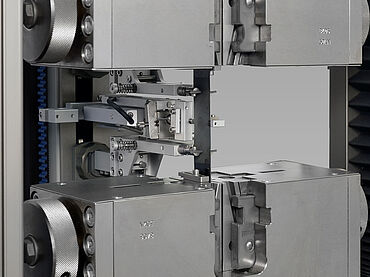

Since deformation takes place within the matrix and the break lies in the matrix or in the interface to the fibers, the shear stress to be measured is relatively low. Tensile forces of 10 kN are rarely exceeded in tests on standard specimens.

Take advantage of the leading testing software in materials testing

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!