Tork test cihazı

İndir- Plastik

- Metal

- Otomotiv

- Medikal teknoloji

- 2,5 - 250 kN

- 2 - 2.000 Nm

- tek eksenli veya çift eksenli burulma testi

Torsiyon testi nedir?

Burulma testi (aynı zamanda burulma testi), bir numunenin dönme nedeniyle oluşan deformasyonunu inceleyen mekanik bir test yöntemidir.

Basitleştirilmiş, burulma, bükülme işlemidir. Çeşitli endüstrilerde kullanılan birçok günlük malzeme, bileşen, bileşen düzeneği ve son kullanım ürünü, öncelikle bu hareket yönünü desteklemek için tasarlanmıştır. Buna vidalar, yaylar, şırınga bileşenleri, teller, borular ve çok daha fazlası dahildir.

Malzeme testi dünyasında, bu burulma hareketini simüle etmek için burulma testi cihazları kullanıyoruz ve üreticilerin aşağıdakiler dahil önemli malzeme özelliklerini belirlemesine yardımcı oluyoruz:

- Maksimum tork

Maksimum tork, numune arızalanmadan önce uygulanabilecek en büyük tork değeridir (burulma kuvveti). Örneğin, bir vida veya cıvata için maksimum tork belirlendikten sonra, bir güvenlik faktörü hesaplanabilir ve ürünün tork derecelendirme spesifikasyonlarına dahil edilebilir. - Burulma dayanımı

Burulma mukavemeti, bir numunenin kırılma mukavemetini ve bir numunenin arızalanmadan önce burulma yüküne dayanabileceği maksimum burulma gerilimini tanımlar. - Burulma kayma gerilimi

Burulma kayma gerilimi, burulma hareketi nedeniyle numunenin bir kesitine etki eden kayma gerilimidir. Burulma yükü, numunenin enine kesiti boyunca, merkezdeki sıfırdan numunenin kenarındaki maksimum burulma kayma gerilmesine kadar değişen, üniform olmayan bir gerilme dağılımı oluşturur. - Elastikiyetin kayma modülü

Elastik kayma sertliği, kayma geriliminin kayma gerilimine oranı olarak tanımlanır. Aynı ürünleri karşılaştırırken: Malzemenin elastisite modülü ne kadar yüksekse sertlik de o kadar fazladır. Bir yapının rijitliği ne kadar büyükse, deformasyona neden olmak için o kadar fazla kuvvet gerekir. - Numunenin kırılma açısı

Kırılma açısı, bir malzemenin burulma momentine maruz kaldığında deforme olabilirliğinin bir ölçüsüdür. Örneğin, ASTM F543-13'e göre, daha büyük bir kırılma açısına sahip bir tıbbi kemik vidası, cerraha maksimum burulma gücüne ulaştığına dair daha erken bir dokunsal uyarı verebilir.

Uygulamaya bağlı olarak, burulma test cihazları, malzeme numunelerini arızaya kadar veya belirli bir tork ve süreye göre test edecek şekilde ayarlanabilir. Uygun cihaz işlevini belirlemek için farmasötik otomatik enjektörler veya vidalı kapaklar gibi bitmiş ürün düzeneklerinde de kullanılabilirler.

Burulma testi için bir test makinesinin uygulama örnekleri

ZwickRoell burulma test cihazları

Burulma testi makinelerimiz ve burulma sürücülerimiz çok çeşitli burulma testlerini kapsar ve özelleştirilebilir.

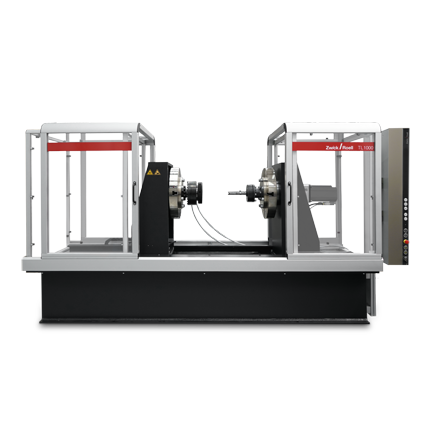

- TorsionLine

Yatay burulma eksenine, bakım gerektirmeyen AC servo sürücüye ve 20 Nm ila 500 Nm veya 1.000 Nm ila 2.000 Nm tork aralığına sahip burulma test cihazı tek eksenli burulma testleri. - zwickiLine

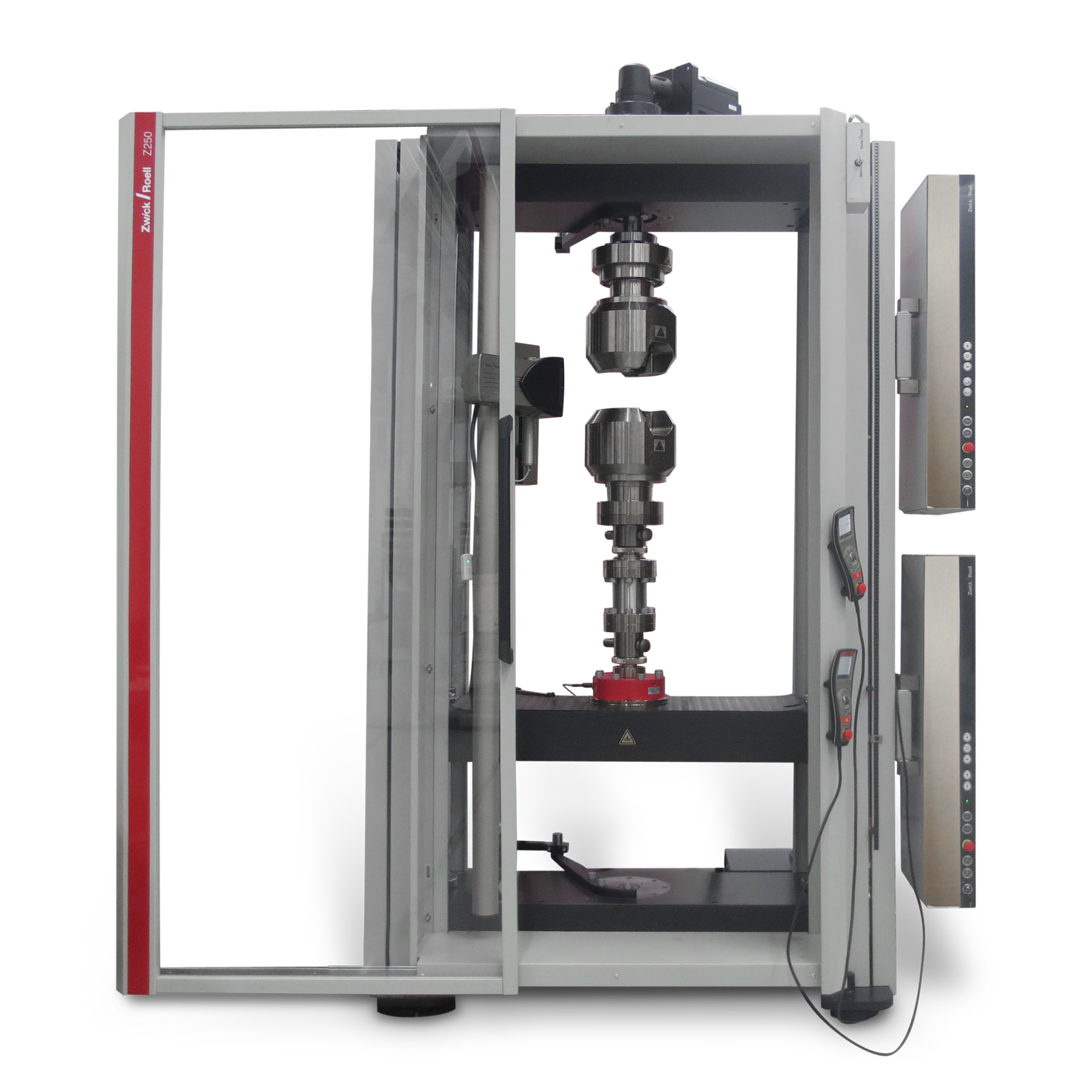

5 kN'ye kadar test kuvvetleri için 2 Nm veya 20 Nm torsiyon sürücüsü ile donatılmıştır tek eksenli veya çift eksenli testler (Burulma ile birlikte gerilim veya sıkıştırma) - AllroundLine

250 kN'ye kadar test kuvvetleri için 200 Nm veya 2.000 Nm torsiyon sürücülü masa veya ayakta duran cihaz tek eksenli veya çift eksenli testler (Burulma ile birlikte gerilim veya sıkıştırma) - Burulma sürücüleri

2 Nm ila 2.000 Nm torklu modüler torsiyonlu tahrikler kolay güçlendirme için mevcut zwickiLine veya AllroundLine malzeme test makineniz.

Test Yazılımı testXpert

Tek eksenli testler ve ZDT testleri (çekme-basma-burulma) için ZwickRoell burulma test cihazları, test araçlarımız ve aksesuarlarımız, testXpert test yazılımımız ve testControl ölçüm ve kontrol elektroniğimizle sorunsuz çalışır.

testXpert III, standartlarla uyumlu bir ana test programına sahiptir, çeşitli test eksenleri için önceden yapılandırılmıştır ve basit fonksiyon blokları ile serbestçe programlanabilen test dizileri için grafik dizi düzenleyicimizi içerir.

Burulma test cihazları nasıl çalışır?

Bir malzeme test cihazının burulma tahriki, dönme hareketinin torkunu ve hızını kontrol eder. Burulma testleri için test cihazları ile test gereksinimlerine bağlı olarak tek eksenli ve çok eksenli yük testleri (çekme-basma-burulma testleri) yapılabilmektedir. .

Bir test gerçekleştirmek için, numune burulma test cihazının çenelerine sıkıştırılır ve numunenin bir ucu, uygulamaya ve test amacına bağlı olarak belirli sayıda devir, belirli bir süre veya arızaya kadar uzunlamasına eksen etrafında bükülür.

Numuneye uygulanan tork veya burulma kuvveti, numunenin bükülmesine neden olur, bu da numunenin enine kesit alanı boyunca bir gerilme dağılımına (kayma gerilmesi) neden olur. Bu, numunenin enine kesiti boyunca tek biçimli gerilim oluşturan çekme veya sıkıştırma yüklerinden farklıdır.

Burulma testinin ortak standartları

- ASTM A938-18 – Standard Test Method for Torsion Testing of Wire

Tel belirli bir hızda bükülür ve kopmaya kadar toplam dönüş sayısı belirlenir. Dönüş sayısı belirlendiğinde, numunenin testi geçtiği kabul edilir. - ASTM F543 – Standard Specification and Test Methods for Metallic Medical Bone Screws

Bu standart, kemiğe implante edilen metalik kemik vidaları için geçerlidir. Vidanın takma veya çıkarma sırasında kırılmamasını sağlamak için burulma dayanımı test edilir. Ölçülen özellikler, standart koşullar altında burulma akma dayanımı, maksimum tork ve kırılma açısını içerir. - ISO 7800 – Metalik malzemeler - Tel - Basit burulma testi

Bu test, çapı veya karakteristik boyutu 0,1 mm ila 14 mm olan metal telin tek yönde basit burulmada plastik olarak deforme olma yeteneğini belirlemek için kullanılır. Test, numune kırılana veya belirli bir dönüş sayısına ulaşılana kadar devam eder. - ISO 7206-8 Cerrahi implantlar - Kısmi ve tam kalça protezi - Bölüm 8:Burulma gerilimli protez soketlerinin yük kapasitesi

Protez soketleri kullanıma hazır durumda test edilir ve standartta belirtilen döngü sayısı ve test kuvveti sırasında kırılmamalıdır.

Teknik Genel Bakış

| TorsionLine 20/200/500 | TorsionLine 1000/2000 | zwickiLine | AllroundLine | AllroundLine | |

|---|---|---|---|---|---|

|  |  |  |  | |

| Model | Stant test cihazları | Stant test cihazları | Masa test cihazları | Masa test cihazları | Stant test cihazları |

| Test tipi | Tork testi | Tork testi | Çekme-Basma-Tork | Çekme-Basma-Tork | Çekme-Basma-Tork |

| Test Ekseni | yatay | yatay | dikey | dikey | dikey |

| Maks. eksenel kuvvet | - | - | 2,5 kN 5 kN | 50 kN | 250 kN |

| Torsiyon Sürücüsü | 20 Nm 200 Nm 500 Nm | 1.000 Nm 2.000 Nm | 2 Nm 20 Nm | 2 Nm 20 Nm 100 Nm 200 Nm | 200 Nm 2000 Nm |

| Torsiyon sürücüsü sonradan takılabilir | - | - | ✓ | ✓ | ✓ |

| Kullanım örnekleri |

|

|

|

|

|

| Ürün No. | 1020233 | 1023835 | ||

| Mümkün olan eksenel kuvvet | 2,5 | 5 | kN | |

| Sürücü | ||||

| Dönme hızı | 0,01...801 0,01...202 | 0,01 ... 20 | 0,01...801 0,01...202 | U/dk |

| Kısmi daire bağlantı flanşı Ø | 40/753 | 40/753 | mm | |

| Güç tüketimi | 0,5 | 0,8 | kVA | |

| Elektriksel bağlantı değerleri | 230 V AC, 50/60 Hz, 1Ph/PE/N | 230 V AC, 50/60 Hz, 1Ph/PE/N | ||

- Maksimum hız. Yalnızca koruyucu bir cihazla bağlantılı olarak

- Koruyucu cihaz olmadan çalışırken düşük hız

- Ø 20 mm bağlantı cıvatalı ilave adaptör flanşları teslimat kapsamına dahildir.

| Ürün No. | 1020233 | 1023835 | 1027734 | 1027737 | 3005980 | |||

| Mümkün olan eksenel kuvvet | 2,5 | 5 | 5 | 50 | 50 | kN | ||

| Sürücü | ||||||||

| Dönme hızı | 0,01...801 0,01...202 | 0,01 ... 20 | 0,01...801 0,01...202 | 0,002 ... 20 | 0,002...601 0,002...202 | 0,002...20 | 0,005...501 0,005...202 | U/dk |

| Kısmi daire bağlantı flanşı Ø | 40/753 | 40/753 | 75 | 75/115 | 75/115 | mm | ||

| Elektriksel bağlantı değerleri | 230 V AC, 50/60 Hz, 1Ph/PE/N | 230 V AC, 50/60 Hz, 1Ph/PE/N | 230 V AC, 50/60 Hz, 1Ph/PE/N | 230 V AC, 50/60 Hz, 1Ph/PE/N | 400 V AC, 50/60 Hz, 3Ph/PE/N | |||

| Güç tüketimi | 0,5 | 0,8 | 2,3 | 2,3 | 5 | kVA | ||

- Maksimum hız. Yalnızca koruyucu bir cihazla bağlantılı olarak

- Koruyucu cihaz olmadan çalışırken düşük hız

- Ø 20 mm bağlantı cıvatalı ilave adaptör flanşları teslimat kapsamına dahildir.

| Ürün No. | 1024998 | 1025005 | ||

| Mümkün olan eksenel kuvvet | 250 | 250 | kN | |

| Sürücü | ||||

| Dönme hızı | 0,001 ... 10 | 0,001 ... 10 | 0,002 ... 10 | U/dk |

| Kısmi daire bağlantı flanşı Ø | 115/2201 | 115/2201 | mm | |

| Elektriksel bağlantı değerleri | 230 V AC, 50/60 Hz, 1Ph/PE/N | 400 V AC, 50/60 Hz, 3Ph/PE/N | V | |

| Güç tüketimi | 2,2 | 5 | kVA | |

- Ek adaptör flanşları ile birlikte gelir

| Tip | TL 020 | TL 200 | TL 500 | |

| Ürün No. | 1026875 | 1026878 | 1026879 | |

| Cihaz gövdesi | ||||

| Test Momenti (sol/sağ) | 20 | 200 | 500 | Nm |

| Koruyucu cihazla toplam yükseklik | 1775 | 1775 | 1775 | mm |

| Koruyucu kapaklı toplam genişlik | 1475 | 1475 | 1475 | mm |

| Toplam derinlik | 650 | 650 | 650 | mm |

| Test ekseninin miktarı | ayarlamak | ayarlamak | ayarlamak | |

| Koruma ünitesi | elektrik kilitli | elektrik kilitli | elektrik kilitli | |

| Tork dönüştürücünün burulma koruması | manuel işletilen, elektrikle izlenen | manuel işletilen, elektrikle izlenen | manuel işletilen, elektrikle izlenen | |

| Elektronik üniteli ağırlık, koruyucu kapak, tork dönüştürücü | 185 | 188 | 188 | kg |

| 4 Çene Tertibatı ile Sıkma Aralığı, maks. | 510 | 510 | 510 | mm |

| Üniversal flanşlı sıkma uzunluğu (çene olmadan), maks. | 680 | 680 | 680 | mm |

| Numunelerin/Numune tutucuların çapı, maks. | 200 | 200 | 200 | mm |

| Cilalama | RAL 7011 ve RAL 7038 | RAL 7011 ve RAL 7038 | RAL 7011 ve RAL 7038 | |

| Ortam sıcaklığı | +10 ... +35 | +10 ... +35 | +10 ... +35 | °C |

| bağıl nem (yoğuşmasız) | 20 ... 90 | 20 ... 90 | 20 ... 90 | % |

| Gürültü düzeyi | 70 | 70 | 70 | dB(A) |

| Burulma direnci | > 1000 | > 1000 | > 1000 | Nm/° |

| Taşıyıcıyı hareket ettirirken eksenel sürtünme kuvveti (burulma yükü olmadan), yakl. | 4 | 4 | 4 | N |

| Sürücü | ||||

| Dönme hızı | ||||

| devir sayısı | 0,0005 ... 180 | 0,0005 ... 90 | 0,0005 ... 50 | U/dk |

| derece olarak | 0,072 ... 64800 | 0,036 ... 32400 | 0,036 ... 18000 | °/dk |

| Sürücünün açısal çözünürlüğü | 3,29 | 1,89 | 0,92 | Açı/Digit |

| Konumlandırma-Tekrarlanabilirlik (ters yön hariç) | ||||

| 1000 °/dak’da | ≤ 20 | ≤ 10 | ≤ 10 | Açı saniye |

| Şu anki geçişi | < 1 | < 1 | < 1 | Açı dakika |

| Bağlantı değerleri | ||||

| Elektrik bağlantısı | 230 | 400 | 400 | V, 1 Ph/N/PE |

| Güç tüketimi | 2,2 | 5 | 5 | kVA |

| Frekans | 50/60 | 50/60 | 50/60 | Hz |

| Tip | TL 1000 | TL 2000 | |

| Ürün No. | 1026880 | 1026881 | |

| Cihaz gövdesi | |||

| Test Momenti (sol/sağ) | 1000 | 2000 | Nm |

| Koruyucu cihazla toplam yükseklik | 1450 | 1650 | mm |

| Koruyucu kapaklı toplam genişlik | 2358 | 2580 | mm |

| Toplam derinlik | 860 | 843 | mm |

| Test ekseninin yerden yüksekliği | 935 | 958 | mm |

| Koruma ünitesi | elektrik kilitli | elektrik kilitli | |

| Elektronik üniteli ağırlık, koruyucu kapak, tork dönüştürücü | 1500 | 1400 | kg |

| Yüz plakalı sıkıştırma uzunluğu, çene olmadan, maks. | 1000 | 1000 | mm |

| Numunelerin/Numune tutucuların çapı, maks. | 600 | 600 | mm |

| Cilalama | RAL 7011 ve RAL 7038 | RAL 7011 ve RAL 7038 | |

| Ortam sıcaklığı | +10 ... +35 | +10 ... +35 | °C |

| bağıl nem (yoğuşmasız) | 20 ... 90 | 20 ... 90 | % |

| Gürültü düzeyi | 62 | 62 | dB(A) |

| Burulma direnci | > 11.500 | > 11.500 | Nm/° |

| Numune hazneleri | |||

| Ön panel yük çerçevesine (dişli kutusu, tork transdüseri) bağlantı | |||

| Çap numune flanşı, sürücü tarafı | 400 | 400 | mm |

| Sürücü | |||

| Dönme hızı | |||

| devir sayısı | 0,0005 ... 20 | 0,0005 ... 10 | U/dk |

| derece olarak | 0,18 ... 7200 | 0,18 ... 3600 | °/dk |

| Sürücünün açısal çözünürlüğü | 0,5 | 0,2397 | Açı/Digit |

| Konumlandırma-Tekrarlanabilirlik (ters yön hariç) | |||

| 1000 °/dak’da | ≤ 5 | ≤ 5 | Açı saniye |

| Şu anki geçişi | < 5 | < 5 | Açı dakika |

| Bağlantı değerleri | |||

| Elektrik bağlantısı | 400 | 400 | V, 3 Ph/N/PE |

| Güç tüketimi | 5 | 5 | kVA |

| Frekans | 50/60 | 50/60 | Hz |

Dokümanlar

- Ürün bilgisi: burulma testleri için zwicki-Line PDF 226 KB

- Ürün bilgileri: Burulma testleri için tezgah test cihazı PDF 449 KB

- Ürün bilgileri: Burulma testleri için stant test cihazı PDF 248 KB

- Ürün bilgileri: TorsionLine 20 - 500 Nm PDF 263 KB

- Ürün bilgileri: TorsionLine 1000 - 2000 Nm PDF 338 KB

Torsiypn test cihazları hakkında sık sorulan sorular

Burulma testi (aynı zamanda burulma testi), bir numunenin büküldüğü mekanik bir test yöntemidir.

Burulma testi, malzeme üreticilerinin önemli özellikleri belirlemesine yardımcı olmak için burulma hareketini simüle eder. Bunlar arasında maksimum tork (burulma kuvveti), burulma mukavemeti (burulma yükü altında kırılma mukavemeti), burulma kayma gerilmesi, elastik kayma sertliği (esneklik kayma modülü) ve numunenin kırılma açısı (deformabilite) yer alır.

Burulma test cihazları, malzemelerin, bileşenlerin veya son ürünlerin burulma hareketini simüle eder. Bir malzeme test cihazının burulma tahriki, dönme hareketinin torkunu ve hızını kontrol eder. Bir testi gerçekleştirmek için numune, burulma test cihazının numune tutucusuna sıkıştırılır. Uygulamaya ve testin amacına bağlı olarak, numunenin bir ucu uzunlamasına eksen etrafında belirli sayıda devir için, belirli bir süre veya kopana kadar döndürülür.

Malzeme testi dünyasında, burulma hareketini (bükülmeyi) simüle etmek ve günlük malzeme, bileşen veya son kullanım ürünü üreticilerine temel malzeme özelliklerini belirlemede yardımcı olmak için burulma test cihazları kullanıyoruz. Uygulama örnekleri çok çeşitlidir ve ilaç ve medikal endüstrisindeki kemik vidaları, Luer-Lock bağlantıları, ilaç kalemleri, vidalı kapaklar üzerinde burulma testlerinden eksantrik milleri üzerindeki burulma yüklerine ve bağlantı elemanları, vidalar, teller gibi metalik malzemeler üzerinde burulma testlerine kadar uzanır.