Sertlik testi ve sertlik testi yöntemleri

Sertlik testinin bir tanımı olarak Martens, 1900 civarında önerdi: “Sertlik, bir batıcının başka bir (daha sert) batıcı penetrasyonuna karşı koyduğu dirençtir.” Açık olduğu kadar basit olan bu tanım, teknik alanda kendini kanıtlamış ve bugüne kadar muhafaza edilmiştir. Teknik sertlik, bir malzeme veya malzeme durumunu tanımlamak için kullanılan mekanik bir parametredir.

Sertlik doğrudan ölçülemez, ancak birincil ölçülen değişkenlerden (örn. Test kuvveti, penetrasyon derinliği, girinti alanı) elde edilir. Sertlik testi yöntemine bağlı olarak, sertlik değeri belirlenir:

- test kuvvetinden ve sertlik ölçüsünü karakterize eden bir geometrik değişkenden (örn. penetrasyon derinliği)

- yalnızca sertlik izlenimini karakterize eden bir uzunluk aracılığıyla

- farklı bir malzeme tepkisi nedeniyle (ör. çizilebilirlik)

Sertliğin tanımı Sertlik neye bağlıdır? Sertliği ölçmek Sertlik testinin amacı Sertlik testi yöntemlerine genel bakış Statik ve dinamik sertlik testi yöntemleri Ortak normlar Yük aralıklarının sınıflandırılması Kuvvet uygulama çeşitleri Tarihçe

Hakkında detaylı bilgi:

Sertliğin Tanımı

Sertlik bir malzemenin (numune parçası) başka, daha sert bir cismin (batıcı uç) mekanik penetrasyonuna karşı gösterdiği mekanik dirençtir.

En sert doğal malzeme elmastır. Bu bir girinti (endüstriyel elmas) olarak kullanılır.

Sertliğin tanımı, bir malzemenin deformasyona ve ayrılmaya karşı direnci olan mukavemet tanımından farklıdır.

Sertlik neye bağlıdır?

Sertlik, bir malzemenin temel bir özelliği değildir. Bununla birlikte, belirli malzemelerin hareket ettiği sertlik aralıkları vardır. Sertlik ısı ile değiştirilebilir, yani bir iş parçası ısıl işlemden sonra farklı (daha yüksek) bir sertlik değeri alır.

Sertlik için sabit bir değer yoktur. Bir sertlik testinin parçası olarak belirlenen sertlik değeri şunlara bağlı olabilir:

- test yöntemlerin seçimi

- girintiye uygulanan test kuvveti

- girintinin malzemede kalma süresi

- girinti geometrisi

- iş parçasının geometrisi

Sertliği nasıl ölçersiniz?

Metalleri sertlik açısından test ederken, öncelikle statik kuvvete sahip yöntemler kullanılır. Ya penetrasyon derinliği ya da bir girintinin neden olduğu girintinin boyutu ölçülür. Sertlik testinin statik yöntemlerinde, derinlik ölçme yöntemleri ile optik ölçme yöntemleri arasında bir ayrım yapılır.

- Derinlik ölçüm yöntemleri, girintinin kalıcı penetrasyon derinliğini ölçer. Rockwell yöntemi, standartlaştırılmış tek derinlik ölçüm yöntemidir (bkz. ISO 6508, ASTM E18). Standart olmayan derinlik ölçüm yöntemleri de vardır: Brinell ve Vickers derinlemesine (HBT, HVT).

- Optik ölçüm yöntemi ile girintinin kalıcı girinti boyutu ölçülür. Standartlaştırılmış optik sertlik testi yöntemleri, Brinell sertlik testi (ISO 6506, ASTM E10), Knoop sertlik testi (ISO 4545, ASTM E92, ASTM E384) ve Vickers sertlik testidir (ISO 6507, ASTM E92, ASTM E384).

- Alternatif olarak, sertlik testi kapsamında dinamik kuvvet uygulayan yöntemler de kullanılabilir, örneğin Leeb geri tepme yöntemi / Leeb sertlik testi (ISO 16589, ASTM A965), burada bir topun geri tepme yüksekliği ölçülür.

Sertlik testinin amacı

Malzeme testinin bir parçası olarak sertlik test yöntemi`

- Sertlik testi, günümüzde özellikle metaller için en sık kullanılan mekanik malzeme testi yöntemlerinden biridir.

- Bir yandan, bu test yöntemi, diğer malzeme özellikleriyle (örneğin, mukavemet, sertlik, yoğunluk) veya malzemelerin belirli baskılar altındaki davranışıyla (örneğin, aşınma direnci) niteliksel ilişkiler kurmak için kullanılabilir.

- Öte yandan, sertlik testi, nispeten tahribatsız, nispeten basit ve gerçekleştirmesi hızlı bir süreçtir, yani numune yüzeyinde yalnızca küçük yüzeysel yaralanmalar kalır.

- Aynı zamanda kalite kontrol (gelen ve giden malzeme denetimi) için basit bir seçenek sunar. Sertlik testi işlemi, çok çeşitli geometrileri test etmek için de kullanılabilir.

Sertlik testinin görevleri ve hedefleri

- Sertlik testi, malzemeleri ayırt etmek ve temel araştırma (malzeme bilimi, malzeme mühendisliği, malzeme teşhisi) bağlamında malzeme ve teknolojilerin analizi, geliştirilmesi ve iyileştirilmesi için temel bir araçtır.

- Karakteristik değerler (sertlik değerleri), malzemelerin endüstride kullanımı (bir malzemenin teknik olarak ilgili bir bileşen için uygunluğu), kalite güvence kontrolleri sırasında kabulü (gelen ve giden malzeme testi), malzemeler arasında ayrım yapılması (örn. malzemelerin karışması olayı) ve hasar durumlarının aydınlatılması (hasar analizi) için çok önemlidir.

Bir bakışta sertlik testi yöntemleri

| Sertlik testi yöntemi | |||

| Statik kuvvet eylemi | Dinamik kuvvet eylemi | ||

| Sert bir metal bilya veya elmas koni/piramit içeren bir uç, katı bir taban üzerinde duran test numunesinin yüzeyine dikey olarak bastırılır. Test kuvveti, tanımlanmış uygulama ve etki süresi ile darbe yapmadan uygulanır. | Dinamik kuvvete sahip yöntemler, özellikle büyük bileşenler üzerindeki sertlik testleri için kullanılır. | ||

Ölçünün optik ölçümü Girinti, test kuvveti geri çekildikten sonra ölçülür. Ölçülen uzunluk değerleri (köşegen, çap) sertlik değerini hesaplamak için kullanılır. | Derinlik ölçüm yöntemi Penetrasyon derinliği, test yükü altında veya ek test yükü kaldırıldıktan sonra ölçülür. | Enerji ölçümü Darbe ve geri tepme hızı (veya yüksekliği) ölçülür. | |

Sabit test kuvveti altında ölçüm

| Ek test kuvveti kaldırıldıktan sonra ön kuvvet altında ölçüm

|

| |

Statik ve dinamik sertlik testi yöntemleri arasındaki ayrım

Prensip olarak, teknolojide yaygın olarak kullanılan sertlik testi yöntemleri arasında statik ve dinamik kuvvetli yöntemlerde bir ayrım yapılır.

- Öncelikle metallerin sertliğini test etmek için kullanılan statik yöntemlerde, test kuvveti yavaş yavaş artırılır, yani standartlarda belirtilen minimum süre içinde darbesiz uygulanır (grafiğe bakınız).

- Dinamik yöntemde ise test kuvveti aniden uygulanır ve böylece test parçası bir darbe yüküne maruz kalır.

Metaller üzerinde statik sertlik testi yöntemleri için ayırt edici kriterler

Metallerin sertlik testinde, öncelikle aşağıdaki kriterler kullanılarak ayırt edilebilen statik kuvvete sahip yöntemler kullanılır:

- Girinti şekli (bilya, piramit veya koni)

- Girinti malzemesi (sertleştirilmiş çelik, karbür veya elmas)

- Test parçasına uygulanan test kuvvetinin boyutu

- Değerlendirme türü: Girinti tarafından oluşturulan girinti derinliğini (derinlik ölçüm yöntemi) veya girinti boyutunu (optik ölçüm yöntemi) ölçmek.

Ortak sertlik testi standartları

Metallerin sertlik testi, aşağıda listelenen standartlarda (ISO ve ASTM) tanımlanan aşağıdaki yaygın statik yöntemleri kullanır:

| TEST YÖNTEMLERİ | ISO | ASTM |

| Brinell | ISO 6506 | ASTM E10 |

| Vickers | ISO 6507 | ASTM E92, ASTM E384 |

| Rockwell | ISO 6508 DIN 50103 | ASTM E18 |

| Rockwell yönteminde | ISO 642 | ASTM A255 |

| Knoop | ISO 4545 | ASTM E92, ASTM E384 |

| Leeb Sertlik testi (Geri tepme yöntemi) | ISO 16589 | ASTM A965 |

Kauçuk elastik Polimerler ve Elastomerler üzerinde sertlik testinde aşağıdaki yöntemler kullanılır:

| Shore | ISO 7619-1 | ASTM D2240 |

| Bilya batma sertliği | ISO 2039-1 | |

| Rockwell | ISO 2039-2 | ASTM D785 |

| Aletli sertlik testi | ISO 19278 (Tasarım) |

Yük aralıklarına göre sertlik testi sınıflandırması

Sertlik testinde uygulama alanına bağlı olarak farklı ana yükler (test kuvvetleri) kullanılmaktadır. Sertlik testi sırasında bir test parçasına uygulanan ana yükün ne kadar yüksek olduğuna bağlı olarak, ISO'da mikro, düşük yük veya makro sertlik testleri arasında bir ayrım yapılır.

- Makro aralıkta (geleneksel sertlik aralığı), test için büyük test yükleri ≥ 5kgf kullanılır, bu da test parçalarında buna karşılık gelen büyük sertlik girintilerine yol açar. Makro düzeyde sertlik testi yöntemleri arasında Brinell, Vickers ve Rockwell bulunur.

- Düşük yük aralığında bir sertlik testi, test yükünün 0,2 kgf ile 5 kgf arasında olduğu zamandır (test yükü ≥ 0,2 kgf ve < 5 kgf). En yaygın küçük yük yöntemi Vickers'tır. Düşük yük sertlik testi esas olarak küçük parçaları, kalın katmanları ve düşük sertliğe sahip malzemeleri test etmek için kullanılır.

- Mikrosertlik testinde, test parçalarında < 0,2 kgf yalnızca çok küçük girintiler oluşturan düşük test yükleri kullanılır (en yaygın yöntem: Vickers). Bu nedenle, ince tabakaların sertliği veya örneğin bireysel kristalitlerin veya inklüzyonların sertliği, mikro aralıktaki sertlik testi ile belirlenebilir.

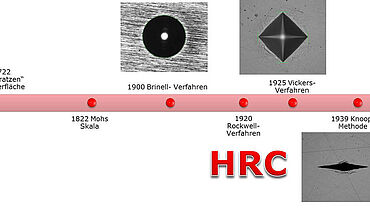

Sertlik Testinin Tarihçesi

- 1722: R. A. Réaumur, minerallerin yüzeyinin çelikle sözde "çizilmesini" geliştirdi.

- 1822: Mohs Kaya testi ölçeği icat edildi. Her malzemenin bir sonraki (daha sert) malzeme ile çizilebildiği, mineraller için on puanlık bir çizilme sertlik ölçeğidir. Mohs sertlik değerleri

- bugün hala mineralojide kullanılmaktadır, ancak teknik malzemelerin (metallerin) sertliğini belirlemek için uygun değildir. Bireysel sertlik seviyeleri nispeten büyüktür ve aralarında farklı mesafeler vardır.

| Mohs'a göre sertlik | Mineral türü | Vickers'e göre Sertlik (HV) |

1 | Konuşmak | 2 HV |

2 | Çene | 35 HV |

3 | Kalkspat | 100 HV |

4 | Fluorspar | 200 HV |

5 | Apatit | 540 HV |

6 | Ortoklas | 800 HV |

7 | Kuvars | 1100 HV |

8 | Topaz | 1400 HV |

9 | Korindon | 2000 HV |

10 | Elmas | 10000 HV |

- 1900: J.A. Brinell, daha sonra Brinell yöntemi haline gelen bir bilya girinti testi geliştirdi.

- 1920: S. R. Rockwell, gemilerini test etmek için kendi adını taşıyan ön kuvvet yöntemini geliştirdi.

- 1925: Vickers yöntemi, İngiltere'de R. Smith ve G. Sandland tarafından icat edildi. Mikrosertlik testini mümkün kıldı.

- 1939: F. Knoop, C. G. Peters ve W. B. E. Emerson, National Bureau of Standards (ABD) Knoop yöntemini geliştirdi.