Innovative Testing Solution for Implantable Neuroelectrodes

CorTec is a young innovative company based in Freiburg im Breisgau, Germany. CorTec is a leading manufacturer of electrode arrays made from traditional implant materials using state-of-the-art laser micromachining, and implantable cables made of biocompatible wires and silicone tubing. For quality assurance and product development the company relies on a testing solution from ZwickRoell.

Neuroelectrodes act as direct interfaces to the brain or nerves. To protect this sensitive tissue as much as possible, the materials cannot be too thick or stiff. At the same time it has to be ensured that the products stand up to a certain amount of strain in the body.

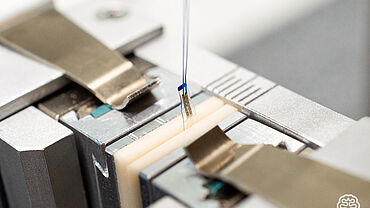

CorTec opted for a zwickiLine testing machine (Fmax 2.5 kN) to perform the testing. Highly sensitive silicone tubing used to coat the electrodes and connections have to be tested in the tensile direction. Wires made of biocompatible metals such as gold, platinum-iridium and coated copper (70µm - 500 µm) must also be tested in the tensile direction. The requirements for both scenarios included the ability to hold the specimens safely and reliably without causing any damage.

Pneumatic grips (200 N) with aluminum convex/Vulkollan jaw inserts were used to hold the silicone tubing. To ensure secure fastening of the very thin wires, screw grips with ceramic inserts were used.

The tests were performed using the Master Test Program for tensile tests, and the measured tensile forces were transfered to testXpert III. With the traceability option available in testXpert III, the specific traceability and documentation demands of these safety-critical tests are fully met. All production steps are performed in qualified and constantly monitored environments (ISO 14644-1, Class 6-9 clean rooms). CorTec has a worldwide research and industry customer base, involved in fundamental research and development of innovative treatments for neurological diseases. The company works closely with a number of university hospitals and research institutes focused in these areas, as well as others with a broader area of interest. The experience in both the academic and medical fields convinced CorTec that ZwickRoell is the right supplier.

Images © CorTec