Vallourec Uses ZwickRoell Materials Testing Machine Z250 for Tribological Testing

Vallourec is a world leader in premium tubular solutions for the energy markets and for demanding industrial applications such as oil & gas wells in harsh environments, carbon capture, utilization and storage, hydrogen transport and storage, new generation power plants, challenging architectural projects, and high-performance mechanical equipment. Vallourec’s pioneering spirit and cutting-edge R&D open new technological frontiers. With close to 17,000 dedicated and passionate employees in more than 20 countries, Vallourec works hand-in-hand with its customers to offer more than just tubes: Vallourec delivers innovative, safe, competitive and smart tubular solutions, to make every project possible.

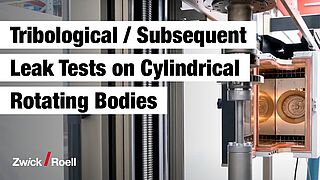

Vallourec continuously develops new tubular connections for specific applications, which in combination with new lubricants, have to withstand a wide range of temperature influences and pressures. In order to test new connections, tribological tests are carried out at the customer site on metallic material pairings using a wide variety of lubricants and a variety of in-service conditions.

Tribology refers to the science of friction, wear and lubrication, and encompasses how interacting surfaces behave in relative motion.

Test procedure

The test is broken down into three different phases. In the first phase, a selected material pair is tribologically loaded. By applying a targeted compressive load up to max. 100 kN and simultaneous rotation of the specimen up to 100 rpm, the screwing-in process of the connections is simulated. The selected lubricant for this process has a significant influence on the friction surface.

To simulate the behavior of a lubricant at drilling depths up to several thousand meters, the second phase of the test involves tempering the ZwickRoell temperature chamber up to 180 °C for 12 hours.

In the last phase, the tightness of the joint is checked under high pressure, for which a hole is drilled in the test specimen. The pin-size cavity between the two metal pairings is then pressurized with a nitrogen/helium mixture at up to 2,000 bar. A sniffer device mounted around the test specimens can identify the leakage from the specimen.