Coil Spring Testing in the Automotive Industry

In conjunction with shock absorbers, suspension springs, also known as coil springs, act as damping elements between the chassis and the body and are crucial for the ride comfort and driving safety of modern vehicles. A suspension spring plays an important role in absorbing road-related shocks and vibrations. It must also provide traction at the wheels.

Coil springs – also known as helical compression springs – are central elements of modern suspension systems. They serve to dampen uneven road surfaces, contribute to driving safety and traction and enable comfortable handling. Their compact design and the possibility of combining them with shock absorbers make them the preferred solution in many vehicle models.

In use, coil springs are loaded axially in the direction of tension or compression. During design, the springs are optimized for the application and vehicle type and must function very precisely according to their specifications and therefore be tested in detail. The total weight of modern electric vehicles is generally even higher than that of vehicles with conventional drive systems, meaning that the springs are exposed to even greater forces. Reliable testing of the springs is therefore extremely important. ZwickRoell’s spring testing system for coil springs is characterized by a unique multi-axial measuring platform with up to nine load cells , which record axial forces as well as transverse forces and lines of force with high precision and determine all spring characteristics. In addition, these lines and points of action can be displayed virtually in real time in the testXpert software test program developed for this purpose.

Typical spring characterisitcs Load vector of coil springs Multi-channel spring system Multi-axial strut testing Spring testing system requirements Request a consultation References

Coil springs – the preferred solution in numerous vehicle models

Helical compression springs (usually referred to as coil springs or sometimes as cylindrical springs) are the best choice for automotive applications because:

- They reliably ensure the ground clearance of the car body,

- They work reliably in harsh environments and their production is economical.

- Their compact design allows for space-saving installation in subframes or on control arms.

- They can be combined with the damper into a single unit (simple strut and McPherson strut).

- They have a linear or even progressive characteristic curve.

DIN EN 15800 Typical characteristic values in coil spring testing

This European standard DIN EN 15800 (replaces DIN 2095) specifies the quality requirements for cylindrical helical compression springs made of spring-hard round wires. Cold-formed compression springs can be manufactured up to a wire diameter of approx. 16 mm. (See also EN 13906-1.)

The most important measurements of a standard coil spring are:

- Spring length [Lo] – nominal length of the coil spring in unloaded state

- Spring forces [F] and spring length [L] are spring characteristics in the work range

- Block length [Lc] – at full compression

- Block force [Fc] – force that occurs on contact with the coils (block length)

- Spring rate [R] – increase in spring characteristics (force per displacement) in N/mm (also known as spring constant, spring stiffness, or spring hardness)

- Transverse forces [Fx, Fy] – for evaluating friction and wear

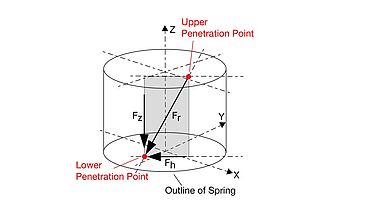

- Penetration points – define the line of action of the resulting force

- Enveloping circle radius [De] – radius of a spring coil in loaded state

- Center dimension – calculates the penetration point at which the force vector penetrates the supporting plane of the spring

Why is it so important to measure the load vector for coil springs?

With coil springs, the load vector never runs along the geometric center axis, since the ends of the spring are not loaded uniformly due to the coil shape and complex multiaxial loads occur. The resulting forces generate transverse forces, tilting moments, and torques that occur in the strut mounting surface and can lead to friction and premature wear of adjacent components – such as struts or valves.

It is therefore crucial to precisely measure the load vector, its penetration points and the horizontal forces and moments/torques in addition to the standard measurements, ideally with a multi-axial spring testing system. This can also be displayed in real time in the respective test program in ZwickRoell’s testXpert testing software.

Multi-channel spring testing system from ZwickRoell

ZwickRoell offers a globally unique multi-channel spring testing system for precise, standard-compliant, and safe testing of coil springs, which works with nine load cells and can therefore also determine the relevant moments:

- 6 vertical sensors (top & bottom)

- 3 horizontal sensors (base platform)

This enables simultaneous measurement of axial and lateral forces, determination of the force centers and calculation of all relevant characteristic values in a fully automatic test sequence. Above all, it makes it possible to determine the penetration points, which are never in the center of the axis of such a spring and therefore have a major influence.

Advantages of the ZwickRoell coil spring testing system at a glance:

- Determination of all relevant spring parameters

- Automated measurement cycle

- 3D display of the resulting forces

- Maximum repeatability

- Freely definable test reports

- Optional enveloping circle measurement

The system tests all types of designs such as cylindrical springs, barrel springs, conical springs, hourglass springs, and beehive springs. Each type of spring comes with specific requirements regarding buckling resistance, lateral stability, space requirements, and vibration behavior – all of which can be reliably analyzed using this system.

Spring testing machine for multi-axial testing of spring struts, i.e. spring-damper units

This spring testing system is equipped with three test axes to measure the damping characteristics of the hydraulic shock absorbers. The vertical force (wheel load) is applied by the testing machine axis. Horizontal forces and torsional moments that occur when maneuvering curves, when starting or braking, etc., are generated by a horizontally mounted electromechanical actuator and a torsion drive. The test axes can be individually and independently controlled from one another. This way you can determine the characteristics (damping friction, viscosity) at different axial speeds with and without lateral forces and torque.

What requirements must the spring testing system meet?

To obtain reliable test results, there are additional requirements for the testing system:

- The machine must have high repeatability, which can be determined using reference springs.

- The compression plates must exhibit high parallelism in an unloaded state.

- Off-center force application along the test axis must not affect the force measurement by more than 1%.

The EN ISO 7500-1 standard, which defines calibration requirements for the verification of static uniaxial testing machines, must be observed. ISO 7500-1 Supplement 2 summarizes the calibration requirements for spring testing machines. In general, force calibration must comply with Class 0.5.