Participation in round robin tests plays a central role in quality assurance and validation of test methods. Round robin tests are proficiency tests, in which different test centers or laboratories perform identical tests to evaluate the accuracy and reproducibility of their test results. They serve to ensure the accuracy of the test results according to international standards.

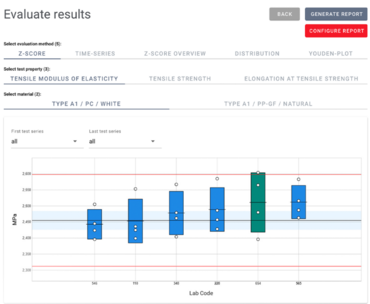

The organization and performance of these round robin tests has often posed considerable challenges for laboratories: The use of manual processes and external providers is not only time-consuming but also cost-intensive and error-prone.LabXplore, a service from ZwickRoell, is the first cloud-based platform that optimizes the planning, performance and evaluation of round robin tests in the field of mechanical test methods and offers laboratories more flexibility, transparency and safety in quality assurance processes.

Use the ZwickRoell platform labXplore for round robin tests to optimize your test processes, check the suitability of your laboratory and ensure maximum accuracy and quality in materials testing!

How can I participate? Which tests are possible? Advantages of labXplore Video Who must perform round robin tests? Definition of Terms

Would you like to find out more about our digital platform for round robin tests - labXplore or setup a date for a demo?

More about labXplore Register free of charge Request a consultation