Short-span compressive strength of a specimen gripped in an S-shape (S-test) to DIN 5014 & ISO 7763

DIN 5014 and ISO 7763 define a test method for determining the strip crush resistance of an S-shaped clamped specimen in the machine direction and have been developed for testing corrugated paper.

They are recommended for paper with a mass per unit area of 80 g/m2 to 220 g/m2.

The compressive strength of an S-shaped gripped specimen is determined similarly to the SCT-Test Paper (Short Span Compression Test) to ISO 9895 / Tappi T826, measuring the maximum compressive force parallel to the paper plane that the specimen can withstand. Thus, the test leads to double flexure loading of the test strip which takes the form of the letter “S”. This is why the test is called an “S-test”. Compared to the short-span compression test, the grips have an offset and a greater distance between them.

The flexure loading of the S-test is comparable to the load that the fluting is subjected to when compressed in a CMT for paper to ISO 7263 corrugated medium test (CMT). In contrast to the CMT, the S-test is carried out directly on the specimen strip and thus prevents fluting in a laboratory fluter, the subsequent sticking on an adhesive tape strip, and the post-conditioning of the paper heated during fluting, and is therefore the faster method.

Test procedure & test tools Materials testing machines Downloads Request a consultation

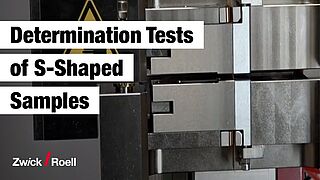

ISO 7763 & DIN 5014: Short-span compression test of a specimen gripped in an S-shape (S-test) with ZwickRoell

- The specimen is secured between two grips with a 1-mm offset from the sheet plane. A compressive load is then applied parallel to the paper plane. This results in a double flexure load at a test length of 4 mm. At maximum load, failure of the structure occurs in the form of buckling

- The ZwickRoell S-test grips to DIN 5014 and ISO 7763 have a pair of jaws with precision vertical and horizontal guidance. The gripping force is applied pneumatically.