Speira Performs Deformation Tests at a Constant Rate of Deformation

Speira is a global aluminum rolling and recycling company. The research & development department performs deformation tests at constant rate of deformation on nonferrous metals.

During a standard tensile test, the material is loaded in only one axis, thereby limiting the degree of deformation. To create flow curves in multiple axes and in a larger degree of deformation range, bulge tests (to ISO 16808) are performed. For this, corresponding tools are used in the sheet metal testing machines.The sheet is clamped between the blank holder and the drawing matrix and then formed by an oil reservoir until break. The resulting strain is measured from above by at least two cameras using Digital Image Correlation (DIC).Since the flow curve of many materials is dependent on the test speed or deformation rate, exact description of the plastic behavior is one of the most important requirements for accurate results and the basis for successful simulations.

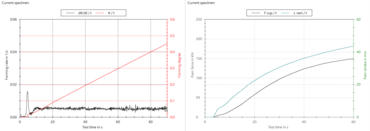

During forming, the material bulges and becomes thinner. The speed of the punch used determines the strain rate of the material. At a constant punch speed, the flow of the material during a test is not constant. However, since the flow curves should be determined at a constant strain rate for simulations, there is a requirement from the field of sheet metal forming to perform strain rate-controlled cupping tests.

In the above-described test, the strain rate in the area of the evaluation zone of the specimen is kept constant—the test begins with a high punch speed, which then continuously decreases.

Strain rate control with testXpert III

ZwickRoell offers the optional functionality of strain rate control for sheet metal testing machines with its testXpert III testing software.The first testing system was delivered this year to the Speira Research and Development Center in Bonn, Germany.

The target/set value is specified via the testXpert III software. The testing system receives the punch speed from the external camera system Aramis (GOM) and controls it accordingly. The measurement results are recorded in GOM and testXpert III.