Stöckli Swiss Sports AG: Materials testing to improve the quality of ski models

Case Study

- Customer: Stöckli Swiss Sports AG

- Location: Malters, Switzerland

- Industry: Lifestyle & Sport

- Topic: Materials testing in ski construction

December 2025

When developing new ski models, Stöckli faced the challenge of reliably testing the adhesion and load-bearing capacity of newly introduced materials. With the Z020 from ZwickRoell, all relevant materials testing – from climbing drum peel tests to flexure and tear-out tests – are efficiently performed in our own laboratory. The result: an accelerated development process and long-term quality assurance.

Tradition and precision in ski construction since 1935

Stöckli Swiss Sports AG is a Swiss company based in Malters that has specialized in the development and manufacture of skis since 1935. The company produces around 75,000 pairs of skis annually, which are distributed to over 30 countries worldwide. In addition to models for recreational use, Stöckli also manufactures high-performance racing skis for alpine skiing and ski cross. All production takes place in Switzerland, combining modern technologies with precise craftsmanship.

The task

Quality assurance during the production process.

A reliable compound between the materials used is a key aspect of ski manufacturing. To assess the adhesion of newly introduced materials within the overall structure, an in-house testing solution was required to deliver precise and reproducible results. The testing method used allows for quantitative assessments of material adhesion and simultaneously supports continuous quality assurance during the production process.

The ZwickRoell solution

In-house solution for quantitative adhesion tests.

A reliable compound between the materials used is a key aspect of ski manufacturing. To assess the adhesion of newly introduced materials within the overall structure, an in-house testing solution was required to deliver precise and reproducible results. With the Z020 AllroundLine from ZwickRoell, all relevant materials testing – from climbing drum peel tests to flexure and tear-out tests – are efficiently performed in our own laboratory.

“Thanks to the extensive testing possibilities in our own laboratory, we ensure that every Stöckli ski meets the highest standards. And this applies to both our athletes and recreational skiers.”

Mathieu Fauve, Head of Research and Development, Stöckli Swiss Sports AG

The result

Fast and reliable development.

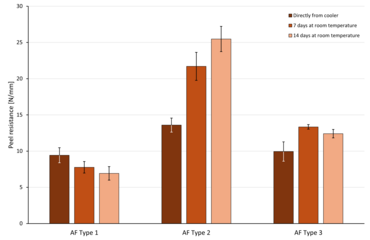

The solution provided by ZwickRoell enables the efficient performance and analysis of important tests in our own laboratory. The testing method used allows for quantitative assessments of material adhesion and simultaneously supports continuous quality assurance during the production process. The following diagram shows where the durability of various adhesive fleece types was tested at ambient temperature.