Ultra-High Temperature Testing on CMCs up to +2,000 °C in Vacuum and Inert Gas Conditions

Ceramic and ultra-high temperature ceramic matrix composites (CMC and UHTCMC) are high-performance materials: they are extremely resistant to high temperatures up to +3,000 °C. These composite materials are used in safety related applications and must withstand high mechanical and corrosive stresses. ZwickRoell offers the perfect high-temperature testing solution for these requirements.

CMCs: high-temperature and break resistant

Ceramic fiber composites consist of fiber coatings and score high points for their high-temperature resistance and damage-tolerant behavior, which prevents crack propagation even under heavy mechanical loads and abrupt temperature changes. Due to their outstanding properties, CMCs are used in the aerospace, automotive and energy sectors, for example for:

- Heat protection systems for spacecrafts

- Gas turbines (turbine combustion chambers, guide vanes, turbine blades)

- Components for engine combustion chambers and gas ducts

- Brake discs for heavy duty disc brakes

- Plain bearings with high corrosion and wear loads

Ongoing development of CMCs under real-life application conditions

The mechanical load bearing capacity of ceramic fiber composites is tested at ultra-high temperatures up to 2,000 °C. This involves evaluating the suitability of CMCs for specific applications using tensile, compression, flexure, creep fatigue and shear tests. To ensure that CMCs are tested under real operating conditions, these destructive test methods are carried out in vacuum and inert gas conditions in a temperature range from 650 °C up to 2,000 °C.

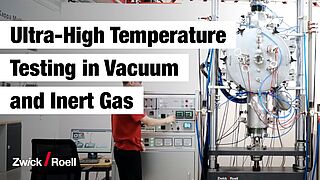

Customized high-temperature testing system with vacuum chamber

The customized high-temperature testing solution is based on the load frame of our Kappa SS-CF creep testing machine. The height- and width-adapted testing machine provides sufficient space for the vacuum and inert gas chamber. This chamber has graphite heating rods and ensures constant temperature distribution on the specimen up to 2,000 °C. At temperatures up to 1,700 °C, the temperature is measured and controlled with type D thermocouples; a two color pyrometer is used for temperatures above 1,700 °C.

Strict requirements on strain measurements up to +2,000 °C

Extreme application conditions such as ultra-high temperatures and diverse environmental conditions also place high demands on strain measurements. Both optical as well as contacting high-temperature extensometers can be used for vacuum and inert gas environments. The laserXtens is particularly suitable for precise non-contact strain measurement in vacuum conditions without having mechanical effects on the specimen.