Adhesion strength of electrode coatings

Whether in an electric car, smartphone, or solar battery in the basement – batteries have become an integral part of our everyday lives. But how do you ensure that these energy storage devices are reliable, durable, and safe? The adhesion strength of electrode coatings plays an often underestimated but crucial role.

Why is adhesive strength so important in electrode coatings?

In lithium-ion batteries – currently the dominant battery type – the electrodes consist of active materials that are applied to metal foils (copper for the anode, aluminum for the cathode). These layers must adhere permanently and firmly, since mechanical stresses occur during the charging and discharging process: The materials expand, contract, and are subjected to thermal stress.

If the adhesion is insufficient, the coating is at risk of coming loose, with consequences such as a loss of power, a drop in capacity or, in the worst case, a short circuit. Adhesion tests therefore not only help to ensure quality, but also prevent potential safety risks.

How is adhesion strength tested?

Two methods have become established in practice:

1. Peel test :

An adhesive tape is applied to the coating and peeled off at a defined angle (usually 90 or 180 degrees). The force required to peel it off shows how strongly the coating adheres. This method is simple and fast, but also susceptible to operator influence.

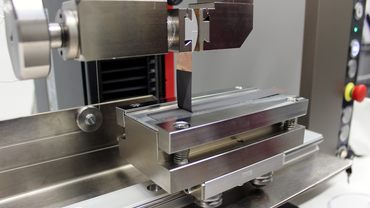

2.Tensile test in the Z-direction:

The adhesive tape is pulled off perpendicular to the surface , which is referred to as the Z-direction.

This method is more reproducible, less dependent on the angle, and is particularly suitable for research and quality control. Modern devices even make it possible to test several specimens at the same time.

Both methods have their merits – manufacturers often use a combination to obtain a more complete picture of the adhesion quality.

What influences the test results?

As is so often the case, the devil is in the details. Even small deviations in specimen preparation can falsify the results:

- Cleanliness and alignment: Residue or uneven sticking will affect adhesion.

- Tape quality: Differences in thickness, composition, or adhesion strength can change the values.

- Environmental conditions: Temperature and humidity also have an effect. Testing should therefore be performed under constant conditions wherever possible – in some cases even in a protective atmosphere.

Practical challenges

A central issue: There are still no uniform standards for adhesion tests on batteries. While other sectors such as the adhesives industry can draw on established standards, battery technologies often lack binding guidelines. Different manufacturers use different methods, which makes comparability difficult.

There is also a need for optimization in specimen preparation. Automated tools that standardize alignment, for example, can help to increase repeatability here, especially with high quantities in series production.

New technologies, new requirements

As battery technology advances, so do the requirements for adhesion:

- Solid-state batteries: They do not use liquid electrolytes, which changes the balance of forces in the cell. A particularly stable connection between the layers is required.

- Silicon anodes: These can expand by up to 300% during charging – a real stress test for any coating. Without sufficient adhesion, there is a risk of delamination and thus loss of function of the cell.

Early adhesion tests during the development phase allow such problems to be identified and solved before they occur in the field.

The path to standards and best practices

As long as there are no global standards, it is up to manufacturers to establish internal standards and clean processes. These include:

- Uniform specimen preparation

- Use of the same adhesive materials

- Testing under stable environmental conditions

At the same time, many companies and test equipment manufacturers are working together to develop reliable testing protocols - a step towards comparability and quality assurance at the industry level.

Conclusion: Small test, big impact

Measuring the adhesion strength of electrode coatings may seem like a minor detail at first glance, but it actually has a huge impact on the safety, efficiency, and service life of modern batteries.

With the increasing use of new cell chemistries and construction methods, this test is becoming even more important. Advances in testing technology, from the Z-direction tensile test to the integration of mechanical, thermal, and electrical measurements, are helping to provide a more comprehensive picture of the behavior of electrodes under real conditions.

The message is clear: If you have adhesion under control, you have the battery under control – today and in the future.