Multifunctional Analysis on Electrodes for Electric Car Batteries – A Practical Look

While the transition to mobility has long been a reality, it also brings with it new challenges for battery cell production. Here, the focus is on the coated electrodes, i.e. the anode and cathode, which enable the flow of electricity in lithium-ion batteries. Even the smallest deviations in production or cell behavior can affect the performance and service life of the battery.

Electrode requirements

Production of these electrodes places high demands on processes, especially in series production:

- Precise layer thicknesses must be consistently maintained over long web lengths.

- Uniform coating is crucial for electrical performance.

- Mechanical stability must be ensured despite high energy density.

- Scalability of processes from the lab to mass production is often critical.

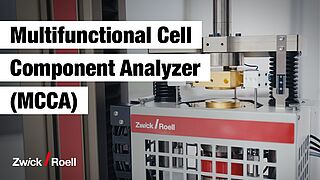

This complexity calls for innovative testing methods - and this is exactly where the Multifunctional Cell Component Analyzer (MCCA) comes into play.

What MCCA can do – and why it’s so important

In one test cycle, the MCCA simultaneously measures the change in thickness (TUC) and the electrical resistance (RUC). This is made possible by three high-resolution displacement sensors, a leveling unit for plane-parallel pressure build-up, and specially developed, gold-plated compression platens for reliable resistance measurement.

There is a well-known effect in battery operation: Battery Swelling – a periodic increase and decrease in cell volume during charging and discharging. This change in volume leads to mechanical stress on the individual layers, which can result in a loss of performance or even damage over many cycles. The MCCA makes it possible to precisely analyze this effect on the smallest cell components, for example coin cells. This is a significant advantage for material development and the optimization of cell structures.

Smarte software included

Thanks to its integration into the testXpert testing software, operating the MCCA is particularly user-friendly: All test sequences are already pre-programmed—one click is all it takes to start the analysis. This not only ensures highly reproducible results, but also saves time and simplifies everyday laboratory work.

Conclusion

The demands placed on modern batteries are constantly increasing – and consequently so is the need for precise measurement technology. The MCCA from ZwickRoell brings the necessary clarity to the analysis of coated electrodes and prototypical cell stacks. Whether in research or in production monitoring: If you want to produce high-performance and safe batteries in the long term, this type of multifunctional analysis is essential.

Know more. Test better. For the batteries of tomorrow.