- Universal

- 0.5 kN - 5 kN

- Tensile test

- Compression test

- Flexure test

- Cyclic tests

- Universal testing applications in a small force range

- Materials testing in clean rooms

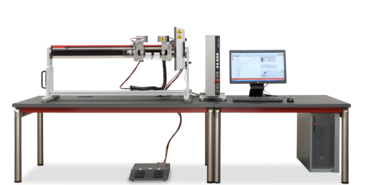

The table-top testing machine for high-performance, flexible and cost-effective testing solutions

The zwickiLine table-top testing machine is equally ideal for research and development as for routine quality assurance testing. Development and manufacture of zwickiLine, including all mechanical, electronic and software components—together with the comprehensive range of accessories—take place at ZwickRoell's production facility in Germany, so all components work together seamlessly.

- The zwickiLine is an easy-to-use, transportable single-column materials testing machine

- It is a high-quality, cost-effective and space-saving testing system

- Because it is lightweight and has a small footprint, this modular system fits easily on any laboratory table.

- Despite the fact that it is small in size and is lightweight, the zwickiLine is an extremely powerful and efficient machine

- For materials testing in class 5 and class 6 cleanrooms, all requirements are met in a force range of 0.5 to 2.5 kN.

Intuitive and workflow-based touch operation

The zwickiLine can be controlled either via a PC or a modern touchscreen. Operating testXpert III is just as easy. Thanks to the intuitive and workflow-based operation, the operator always finds their way around easily - whether they are experienced testers or new employees.

Interested? Contact us now to schedule a demonstration.

Table-top testing machine technical overview

- Depending on type, the zwickiLine table-top testing machine is available with test speeds from 0.0005 to 3000 mm/min. Testing machine speed is independent of test load. Position, force or strain control can be selected as required.

- The high test-speed range can be used without restriction. In addition, test loads up to 110% of machine nominal load are permissible to compensate for heavy combinations of test fixtures, accessories etc.

- zwickiLine is available for test loads from 500N to 5kN and with test-area heights from 565 mm to 1365 mm.

- zwickiLine can be operated with standard commercial PCs or laptops and requires no special expansion cards.

- Low weight, a small footprint and space-saving design allow this modular system to fit easily on to any laboratory table.

Properties according to force range

| Type | Z0.5 TS | Z0.5 TN | Z0.5 TH | Z0.5 TN | Z0.5 TH | |

| Item No. | 1080950 | 1080951 | 1080952 | 1123065 | 1123066 | |

| Test load Fmax | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | kN |

| Test area | ||||||

| Height, Pmin…Pmax (each without mounting stud) | ||||||

| Moving crosshead mounted with angle up | 235 ... 5651 | 235 ... 10651 | 235 ... 13651 | 235 ... 10651 | 235 ... 13651 | mm |

| Moving crosshead mounted with angle down | 90 ... 420 | 90 ... 920 | 90 ... 1220 | 90 ... 920 | 90 ... 1220 | mm |

| Depth | 105 | 105 | 105 | 105 | 105 | mm |

| Width | No limitation | No limitation | No limitation | No limitation | No limitation | |

| Load frame | ||||||

| Dimensions | ||||||

| Height without top crosshead | 7892 | 12892 | 15892 | 12892 | 15892 | mm |

| Width | 4083 | 4083 | 4083 | 4083 | 4083 | mm |

| Width with machine electronics | 4113 | 4113 | 4113 | 4113 | 4113 | mm |

| Depth | 4803 | 4803 | 4803 | 4803 | 4803 | mm |

| Depth with machine electronics | 6223 | 6223 | 6223 | 6223 | 6223 | mm |

| Weight | ||||||

| With machine electronics, approx. | 68 | 76 | 81 | 76 | 81 | kg |

| Average noise level at vmax measured at 1 m distance from the front of the machine | 56 | 56 | 56 | 61 | 61 | dB(A) |

| Drive | ||||||

| Crosshead speed vmin ... vmax | 0.0005 ... 20004 | 0.0005 ... 20004 | 0.0005 ... 20004 | 0.0005 ... 30004 | 0.0005 ... 30004 | mm/min |

| Deviation from the set drive speed, max. | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | % of vactual |

| Drive travel resolution | 0.0554 | 0.0554 | 0.0554 | 0.0830 | 0.0830 | μm |

- Height of the test area without accessories

- The dimension increases by 9 mm with the additional crosshead option (top crosshead)

- With “large base” option: width 583 mm, width with machine electronics 585 mm, depth 565 mm, depth with machine electronics 707 mm.

- Values apply to machines with closed safety door and closed safety guard in automatic mode and to machines without safety device and/or without safety guard. For machines with the safety door and/or safety guard open, the speed is reduced to 600 mm/min.

| Type | Z1.0 TS | Z1.0 TN | Z1.0 TH | |

| Item No. | 058997 | 058998 | 058999 | |

| Test load Fmax | 1 | 1 | 1 | kN |

| Test area | ||||

| Height, Pmin…Pmax (each without mounting stud) | ||||

| Moving crosshead mounted with angle up | 235 ... 5651 | 235 ... 10651 | 235 ... 13651 | mm |

| Moving crosshead mounted with angle down | 90 ... 420 | 90 ... 920 | 90 ... 1220 | mm |

| Depth | 105 | 105 | 105 | mm |

| Width | No limitation | No limitation | No limitation | |

| Load frame | ||||

| Dimensions | ||||

| Height without top crosshead | 7892 | 12892 | 15892 | mm |

| Width | 4083 | 4083 | 4083 | mm |

| Width with machine electronics | 4113 | 4113 | 4113 | mm |

| Depth | 4803 | 4803 | 4803 | mm |

| Depth with machine electronics | 6223 | 6223 | 6223 | mm |

| Weight | ||||

| With machine electronics, approx. | 68 | 76 | 81 | kg |

| Average noise level at vmax measured at 1 m distance from the front of the machine | 55 | 55 | 55 | dB(A) |

| Drive | ||||

| Crosshead speed vmin ... vmax | 0.0005 ... 20004 | 0.0005 ... 20004 | 0.0005 ... 20004 | mm/min |

| Deviation from the set drive speed, max. | 0.05 | 0.05 | 0.05 | % of vactual |

| Drive travel resolution | 0.0554 | 0.0554 | 0.0554 | μm |

- Height of the test area without accessories

- The dimension increases by 9 mm with the additional crosshead option (top crosshead)

- With “large base” option: width 583 mm, width with machine electronics 585 mm, depth 565 mm, depth with machine electronics 707 mm.

- Values apply to machines with closed safety door and closed safety guard in automatic mode and to machines without safety device and/or without safety guard. For machines with the safety door and/or safety guard open, the speed is reduced to 600 mm/min.

| Type | Z2.5 TS | Z2.5 TN | Z2.5 TH | |

| Item No. | 059001 | 059003 | 059004 | |

| Test load Fmax | 2.5 | 2.5 | 2.5 | kN |

| Test area | ||||

| Height, Pmin…Pmax (each without mounting stud) | ||||

| Moving crosshead mounted with angle up | 235 ... 5651 | 235 ... 10651 | 235 ... 13651 | mm |

| Moving crosshead mounted with angle down | 90 ... 420 | 90 ... 920 | 90 ... 1220 | mm |

| Depth | 105 | 105 | 105 | mm |

| Width | No limitation | No limitation | No limitation | |

| Load frame | ||||

| Dimensions | ||||

| Height without top crosshead | 7892 | 12892 | 15892 | mm |

| Width | 4083 | 4083 | 4083 | mm |

| Width with machine electronics | 4113 | 4113 | 4113 | mm |

| Depth | 4803 | 4803 | 4803 | mm |

| Depth with machine electronics | 6223 | 6223 | 6223 | mm |

| Weight | ||||

| With machine electronics, approx. | 68 | 76 | 81 | kg |

| Average noise level at vmax measured at 1 m distance from the front of the machine | 55 | 55 | 55 | dB(A) |

| Drive | ||||

| Crosshead speed vmin ... vmax | 0.0005 ... 10004 | 0.0005 ... 10004 | 0.0005 ... 10004 | mm/min |

| Deviation from the set drive speed, max. | 0.05 | 0.05 | 0.05 | % of vactual |

| Drive travel resolution | 0.0277 | 0.0277 | 0.0277 | μm |

- Height of the test area without accessories

- The dimension increases by 9 mm with the additional crosshead option (top crosshead)

- With “large base” option: width 583 mm, width with machine electronics 585 mm, depth 565 mm, depth with machine electronics 707 mm.

- Values apply to machines with closed safety door and closed safety guard in automatic mode and to machines without safety device and/or without safety guard. For machines with the safety door and/or safety guard open, the speed is reduced to 600 mm/min.

| Description | Value | |

| Type | Z2.5 TN+ | |

| Item No. | 1039527 | |

| Test load Fmax | 2.5 | kN |

| Test area | ||

| Height, Pmin…Pmax (each without mounting stud) | ||

| Moving crosshead mounted with angle up | 365 ... 1040 | mm |

| Moving crosshead mounted with angle down | 125 ... 800 | mm |

| Depth | 105 | mm |

| Width | No limitation | |

| Travel s of the moving crosshead, max. | E = Sum of the installation dimensions of all accessories (load cell, specimen grips/test fixture/test tool, mounting stud) | |

| If E < Pmin | Pmax - Pmin | |

| If E > Pmin | Pmax - E | |

| Load frame | ||

| Dimensions | ||

| Height | 12891 | mm |

| Width | 4082 | mm |

| Width with machine electronics | 4372 | mm |

| Depth | 4802 | mm |

| Depth with machine electronics | 6622 | mm |

| Weight | ||

| With machine electronics, approx. | 127 | kg |

| Paint finish | A6-C31, RAL 7021 and RAL 3038 | |

| Ambient temperature | +10 ... +35 | °C |

| Relative humidity (non-condensing) | 20 ... 90 | % |

| Average noise level at vmax measured at 1 m distance from the front of the machine | 64 | dB(A) |

| Conformity | ISO 9000 and CE | |

| Drive | ||

| Driving power | 500 | W |

| Motor | AC servo motor | |

| Control, set value preselection | Digital | |

| Crosshead speed vmin ... vmax | 0.0005 ... 30003 | mm/min |

| Drive travel resolution | 0.95 | nm |

| Positioning repeatability (without reversing directions) | ±2 | μm |

| Controller | Adaptive | |

| Cycle time | 1000 | Hz |

| Power input specifications | ||

| Version | 500 | W |

| Power supply | 230 | V, 1Ph/N/PE |

| Permissible voltage fluctuation | ± 10 | % |

| Power consumption (full load), approx. | 2 | kVA |

| Power frequency | 50/60 | Hz |

- The dimension increases by 9 mm with the additional crosshead option (top crosshead).

- With “large base” option: width 583 mm, width with machine electronics 611 mm, depth 565 mm, depth with machine electronics 746 mm.

- Values apply to machines with closed safety door and closed safety guard in automatic mode and to machines without safety device and/or without safety guard. For machines with the safety door and/or safety guard open, the speed is reduced to 600 mm/min.

| Type | Z5.0 TS | Z5.0 TN | Z5.0 TH | |

| Item No. | 059005 | 059006 | 059007 | |

| Test load Fmax | 5 | 5 | 5 | kN |

| Test area | ||||

| Height, Pmin…Pmax (each without mounting stud) | ||||

| Moving crosshead mounted with angle up | 365 ... 5401 | 365 ... 10401 | 365 ... 13401 | mm |

| Moving crosshead mounted with angle down | 125 ... 300 | 125 ... 800 | 125 ... 1100 | mm |

| Depth | 105 | 105 | 105 | mm |

| Width | No limitation | No limitation | No limitation | |

| Load frame | ||||

| Dimensions | ||||

| Height without top crosshead | 7892 | 12892 | 15892 | mm |

| Width | 4083 | 4083 | 4083 | mm |

| Width with machine electronics | 4113 | 4113 | 4113 | mm |

| Depth | 4803 | 4803 | 4803 | mm |

| Depth with machine electronics | 6223 | 6223 | 6223 | mm |

| Weight | ||||

| With machine electronics, approx. | 70 | 78 | 83 | kg |

| Average noise level at vmax measured at 1 m distance from the front of the machine | 55 | 55 | 55 | dB(A) |

| Drive | ||||

| Crosshead speed vmin ... vmax | 0.0005 ... 600 | 0.0005 ... 600 | 0.0005 ... 600 | mm/min |

| Deviation from the set drive speed, max. | 0.05 | 0.05 | 0.05 | % of vactual |

| Drive travel resolution | 0.0168 | 0.0168 | 0.0168 | μm |

- Height of the test area without accessories

- The dimension increases by 9 mm with the additional crosshead option (top crosshead)

- With “large base” option: width 583 mm, width with machine electronics 585 mm, depth 565 mm, depth with machine electronics 707 mm.