ISO 5628 | DIN 53121 stiffness under flexure of paper, cardboard, and corrugated board

Stiffness under flexure is of critical importance in the further processing of paper and cardboard. To enable reliable, trouble-free operation of packaging and filling machines, the paper or cardboard must be flexible within defined limits. At paper feed changeover, uniform stiffness properties are also essential for smooth operation of the packaging machine.

The international standard ISO 5628 specifies three test methods for determining the stiffness under flexure of paper and cardboard: the 2-point flexure test, the 3-point flexure test, and the 4-point flexure test. The two-point flexure method and three-point flexure method are suitable for thin paper and cardboard. The four-point flexure method is recommended for thicker corrugated board and cardboard.

The German industry standard DIN 53121 describes the width-related determination of the flexural strength of paper and cardboard using the beam method according to the three test methods, whereby the testing of corrugated board is prescribed in the 4-point test method.

ISO 2493-1 specifies methods for determining the flexural strength of paper and cardboard that are specifically based on the principle of two-point loading.

2-point flexure test 3-point flexure test 4-point flexure test Materials testing machines Request a consultation

2-point flexure test to ISO 5628, DIN 53121, and ISO 2493-1

The two-point flexure method is the most common method used to determine stiffness under flexure of paper and thin cardboard and is defined in the standards ISO 5628, DIN 53121, and ISO 2493-1. The customer's specifications primarily determine which standard to use.

In the 2-point flexure test, the paper strip is gripped at one end and loaded with a test die on the exposed side. This method is particularly simple and is often used in research and quality control.

ZwickRoell's 2-point flexure test kit covers two applications: measurement of stiffness under flexure and determination of folding characteristics up to a maximum bending angle of 120°. Accurate, high-resolution measuring technology eliminates the need for a change of load cell.

ZwickRoell 2-point flexure test kit

The ZwickRoell 2-point flexure test kit enables the determination of the stiffness under flexure according to the various standards and can be used in a zwickiLine universal testing machine. Our fixture has the following advantages and features:

- Bending forces are recorded by a load cell with a measurement error of just 1%.

- Positioning of the load cell away from moving machine parts avoids signal interference.

- Electronic angle measurement with 0.001° resolution guarantees maximum reliability for measured values.

- Specimens up to 50 or 100 mm wide can be clamped.

- The gauge length is freely adjustable.

- The kit is available with three different clamping systems: screw clamping, spring clamping and pneumatic clamping.

3-point flexure test to ISO 5628 and DIN 53121

A 3-point flexure test to ISO 5628 and DIN 53121 is rarely used to determine stiffness under flexure for paper-based materials. Applications include solid board, paper-based composites and reel cores. However, the 4-point flexure test is standardized for reel cores; 3-point flexure tests are usually also performed to factory standards.

For the 3-point flexure test, an inexpensive 3-point flexure tool without flexure transducer from the ZwickRoell modular system is available. We also offer customized solutions for measurements on core reels.

Buckling resistance of corrugated board to DIN 54608

This 3-point flexure test is performed to determine the buckling resistance of corrugated board to DIN 54608.

The test is used for advanced characterization of multi-wall corrugated products.

Performing the determination is simple and requires only relatively small specimen sizes.

The value depends on various basic parameters:

- SCT of the output paper

- Flute geometry

- Quality of the board adhesion

- Development of material flaws, such as plastic deformation during the manufacturing/molding processes, development of vacuum lines, etc.

4-point flexure test on corrugated board to ISO 5628 and DIN 53121

Corrugated board is tested exclusively using the 4-point flexure method.

The test result is the stiffness, which is related to the specimen width. Stiffness is a characteristic value of corrugated board that can be used to estimate the strength of a corrugated board box in advance.

In the four-point flexure method, the specimen is supported at four points, and a uniform load to test the material under more realistic conditions is applied.

In the 4-point flexure test the stiffness under flexure of corrugated board is determined in accordance with DIN 53121 or ISO 5628. The 4-point flexure test delivers reliable stiffness values in the machine and transverse directions. This is particularly important for mini-flute corrugated board, where the stiffness of the board plays a significantly greater role than with standard flute heights.

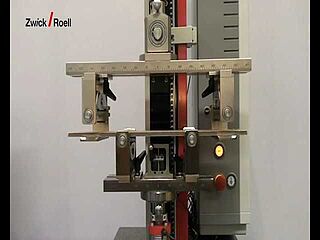

ZwickRoell 4-point flexure test kit

ZwickRoell has developed a 4-point flexure test kit for cardboard and corrugated board based on the knowledge gained from flexure test kits for structural materials (aircraft construction, ceramics, and high-performance metals):

- An economical tool that meets all ISO 5628 and DIN 53121 requirements and can be used from the smallest machine, our zwickiLine universal testing machine up to 5 kN.

- In contrast to instruments that use weights for specimen loading, operation is quick and straightforward. The specimen is simply positioned on the flexure test kit and the test is started. Stiffness is calculated automatically, with allowance for elastic limits.

- The anvils supplied with the flexure test kit are designed to fully accommodate the properties of corrugated board, allowing even warped or buckled specimens to be tested in many cases. Measurement is possible even with production-related self-deformation of specimens.

- The deflection of the corrugated board is measured using a measuring transducer or alternatively, in the case of tests on microflute corrugated boards (e.g., E or F flutes), using optical displacement transducers to prevent mechanical influences caused by the spring force of the measuring transducer.