Internal Bond Test ISO 15754 | Tappi T541

The internal bond test — also called the Z-direction tensile test — is a standardized method used to measure the tensile strength perpendicular to the plane of the paper (Z-direction) for paper and cardboard and defined in the standards ISO 15754 and Tappi T541.

The purpose of the test is to determine the adhesive strength of the layers within the material, i.e., how well the fibers or layers adhere to each other. The bond strength between the layers of multi-layer materials (duplex or coated papers) is measured. The internal bond test helps to assess the tendency to delaminate or burst during processing (e.g., punching, folding, printing).

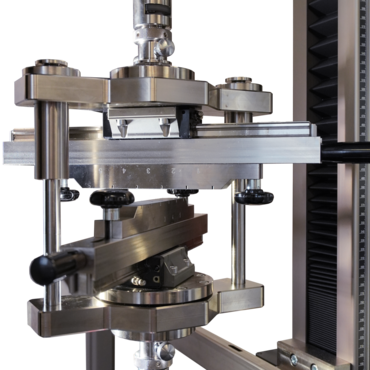

To keep the testing equipment from influencing the separation of the layers, the force must continue to act vertically even if the specimen fails, for which high transverse stiffness and absolute parallelism of the specimen grips are primary prerequisites.

Test procedure & test equipment Video Comparison with the Scott bond test Materials testing machine Downloads Request a consultation

Internal bond test to ISO 15754 and Tappi T541 with ZwickRoell

ZwickRoell has a special test device for the standard-compliant determination of tensile strength in the Z direction (internal bond strength), which guarantees reliable test results thanks to its absolute parallelism and transverse stiffness.

- Specimen carriers arranged at 90° to each other enable five individual specimens to be tested in succession with a single application.

- The specimen carriers are mounted on precision compression platens and are accordingly parallel and stiff in the tensile and transverse directions.

- Specimen application: a specimen is attached to one specimen carrier using double-sided adhesive tape. Double-sided tape alone is applied to the opposing second carrier.

- During the test sequence the specimen is initially pressed against the second specimen carrier. Compressive force and duration are freely adjustable.

- The specimen is then separated in less than half a second in the tensile test.

- The measured quantity is the tensile strength, related to the surface area of the specimen, yielding the tensile stress.

- Pressing on specimen plus tensile test in one operation.

- Tests using half the test area are possible for high-strength specimens.

The fixture is suitable for use in ZwickRoell universal testing machines of the zwickiLine, ProLine, and AllroundLine series.

Internal bond test compared to the Scott bond test

The internal bond test offers greatly reduced result dispersion compared to the Scott bond test, which is used to determine similar paper properties. A pendulum impact tester is used for the Scott bond test. The test therefore takes into account the high processing speeds typical for this material, but is considerably less reproducible due to internal energy losses through friction and vibration. Other similar tests include ply-bond strength to DIN 54516 and the Scott bond test to TAPPI T569, both of which apply peel loading to the specimen.