Battery Swelling - Which Test Method is the Most Suitable for EV batteries?

When pouch cells and prismatic lithium-ion cells age, they expand (Battery Swelling). This leads to increased pressure in the battery pack and impairs the electrical performance. Conventional battery management systems (BMS) do not detect this pressure or its effects, which leads to inaccurate predictions of the state of charge (SOC) and state of health (SOH) as the battery ages.

The test bench developed by ZwickRoell and MBTS will significantly improve the future development of battery packs.

Video on Battery swelling Current challenges Video on newly developed testing systemComparison climatic chamber vs. ZwickRoell / MBTS test bench Advantages Contact us

Focus on battery testing: Safety, efficiency, progress

Lithium-ion batteries are key components of the electrification of the transport and traffic sector. Research and development along with comprehensive quality assurance play an important role in the further development of battery cell components, battery cells, battery packs, and complete high-voltage storage systems. Therefore, the battery testing to characterize the materials used, the determination of the properties of intermediate product characteristics as well as analysis of cell behavior are crucial prerequisites for progress..

In addition to mechanical testing of battery components, multi-functional or multiphysical testing on cells and cell systems are also important. They ensure operation reliability and safety during high-voltage storage development. This can be used to characterize the battery behavior during the charging and discharging process. This procedure sometimes generates valuable data for the further development of battery management systems (BMS).

Current challenges in the development, production and quality assurance of lithium-ion batteries

In LIB (lithium-ion battery) technology, pouch cells and prismatic cells are typically arranged in battery packs using either cell-to-pack or cell-to-module configurations. To ensure optimal electrical performance, a certain degree of mechanical pre-compression is applied during production. This controlled pressure is crucial, as insufficient compression leads to reduced capacity, reduced electrical performance and accelerated aging. In turn, too much pressure has similarly negative effects.

Mechanical pressure is important for the life cycle of the battery pack. The reason: The cells expand and contract again during the charging and discharging process. This process is also known as “breathing”. Over time there is a gradual swelling (battery swelling), due to the aging process. These changes lead to an increased internal pressure in the battery pack, which may exceed the ideal operating conditions. Therefore, maintaining precise control of this mechanical pressure is relevant and important to maintain the efficiency and longevity of the battery. It is therefore crucial to pay attention to this when designing a battery pack in order to provide optimal conditions for the cells, to determine the ideal conditions for the cell, for example by means of a single cell test [1, 2].

However, a testing system that measures and controls both temperature and pressure synchronously and can execute electrical protocols, is not currently on the market. For this reason, a new testing system for the characterization of battery cells has been developed.

Innovative multifunctional testing system vs. state of the art solution with climatic chamber

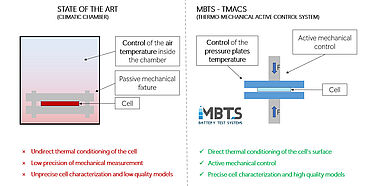

The synchronous control of temperature and pressure during LIB operation has been made difficult thus far due to technical limitations. Climatic chambers can only indirectly control the temperature of the LIB, by adjusting the air temperature in the chamber. In addition, the the mechanical pressure control on the cell can only be achieved via passive systems, since an active pressure would require a larger climatic chamber and could lead to problems due to non-optimal temperature conditions.

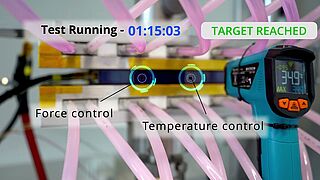

Researchers from ZwickRoell and MBTS have therefore developed a new method with which the surface temperature and the mechanical pressure on pouch and prismatic cells can be controlled or measured with high precision during the charging and discharging process. [3] This innovative system enables precise measurement of mechanical, thermal, and electrical parameters, while simultaneously isolating the effects of temperature and pressure on performance. Figure 1 clarifies the technological differences and advantages between climatic chambers and the new testing technology.

The compression platens with integrated active thermal conditioning are a patented system of MBTS GmbH. This system applies mechanical pressure to the cell and also controls the surface temperature of the cell. The entire electrothermal mechanical system is fully automated to enable fast and precise protocols. And at the same time, it reduces user influences.

New method of multiphysical sensitivity analysis

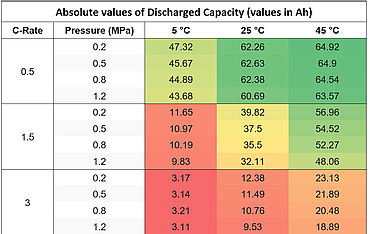

A recent study by ZwickRoell and MBTS attempted to quantify the the effect of mechanical pressure, temperature and discharge rates on the power loss of pouch lithium-ion cells. [2] For this purpose, LGe66 cells were discharged at different C rates, pressure and temperature conditions. The results provide valuable insights into optimizing the design of battery packs and ensuring long-term reliability in energy storage systems. The study was conducted under controlled conditions and three temperatures (5°C, 25°C and 45°C), four pressure levels (0.2 MPa, 0.5 MPa, 0.8 MPa and 1.2MPa) and three discharge rates (0.5 C, 1.5 C and 3.0 C) were examined.

The following findings from current scientific studies are confirmed by the study:

Increased pressure has a negative effect on performance. Higher temperatures, in turn, increase the capacity. However, the extent of these effects varies based on specific operating conditions. For example, at a temperature of 5°C and a discharge rate of 0.5 C, an increase in pressure from 0.2b MPa to 1.2 MPa would result in a 5.84 percent reduction in discharge capacity. In contrast, the reduction at 45°C would only be 2.17 percent. Similarly, an increase in temperature from 25°C to 45°C at 0.5 C and 0.2 MPa results in an improvement in discharge capacity of 4.27 percent. At a higher discharge rate of 1.5 C, the same temperature shift led to a significant increase in discharge capacity of 43.04 percent.

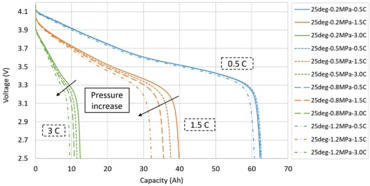

As shown in Figure 2, there is a connection between the discharge capacity and the C rate at different temperatures and pressure levels. The increase in pressure does not cause the same capacity decline as soon as the C rate and/or temperature change. This indicates a multiphysical correlation between these parameters.

Table 1 lists the numerical values of this discharge capacity for all tested charging cases. An interesting observation is that at low temperature (5°C) and high C rate, the effect of pressure seems to be negligible. The nominal discharge capacity of the cell under investigation is 66 Ah.

These results illustrate the complex and non-linear interaction of temperature, pressure and discharge rates in the performance of lithium-ion batteries. The results underline the importance of actively managing temperature and pressure during battery operation to ensure optimal efficiency and reliability.

The newly developed test system makes it possible to quantify correlations between the C rate, the pressure and the temperature with high accuracy. The implications for the development and management of battery packs are enormous, as explained below.

Technical advantages for the battery management system

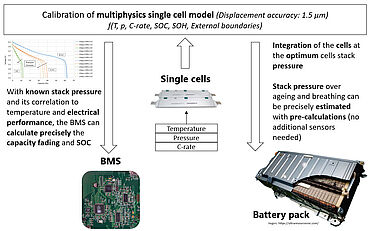

With the additional insights gained from the single-cell test, the focus of high-voltage storage development is now on achieving the optimal pressure within the cell pack. This avoids loss of performance and aging effects. However, due to the battery swellings pressure fluctuations continue to occur. The pressure behavior resulting from this phenomenon can be calculated during the development phase and transferred to the BMS as a pre-calculation. This approach eliminates the need for additional pressure sensors in the battery pack.

As a result, the actions of the BMS are more effective, since the stack pressure could be estimated based on the conditions of the cell's charge and health. This would result in a more precise prediction of the electrical performance of the battery pack. Figure 3 shows a schematic diagram of the procedure.

Technical and economic advantages for high-voltage storage development

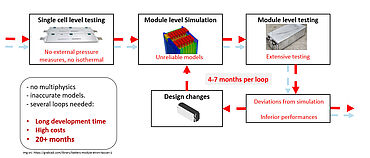

During the development of a battery pack, a simulation test loop for the standard version is followed, which comprises several stages:

- Testing and modeling of a single cell

- Simulation of homogeneous procedures at module and pack levels

- Prototyping and testing.

If the tests fail, the process must be repeated, which requires additional resources. A common example of this is when a driving cycle cannot be completed due to insufficient battery pack capacity. This is often due to excessive stacking pressure, which leads to degeneration of the cells.

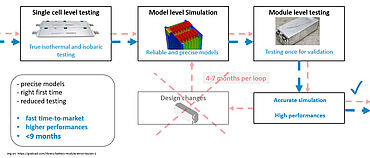

By precisely measuring the shift in single-cell expansion, with an accuracy of 1 µm, and evaluating the electrical performance under certain pressure conditions, the developed models can predict whether a design can lead to insufficient performance or failure.

This predictive capability enables more efficient design processes and shortens the iterative development cycles, as shown in Figure 5.

Outlook

The current geopolitical landscape is increasing the pressure on the automotive industry to accelerate technological progress and remain competitive. The optimization of development and production processes is a decisive step towards reducing costs and meeting market requirements. The illustrated solution considers this goal, for example by increasing development efficiency and helping to deliver a high-quality product.

References

[1] Mussa, A.S.; Klett, M.; Lindbergh, G.; Lindström, R.W. Effects of external pressure on the performance and ageing of single-layer lithium-ion pouch cells. J. Power Sources 2018, 385, 18–26.

[2] Li, R.; Li, W.; Singh, A.; Ren, D.; Hou, Z.; Ouyang, M. Effect of external pressure and internal stress on battery performance and lifespan. Energy Storage Mater. 2022, 52, 395–429.

[3] Aiello, L.; Ruchti, P.; Vitzthum, S.; Coren, F. Influence of Pressure, Temperature and Discharge Rate on the Electrical Performances of a Commercial Pouch Li-Ion Battery. Batteries 2024, 10, 72.

ABOUT THE AUTHOR:

CEO and co-founder of MBTS GmbH

As co-founder and CEO of MBTS, he has specialized the company in the development of high-precision multiphysics testing systems for pouch and prism cells. Prior to that, he worked for several years as a development and analysis engineer at Samsung SDI Battery Systems and AVL. At the same time, he earned his doctorate at the Graz University of Technology in the field of safety assessment of lithium-ion batteries.