Horizontal Catheter Testing System for Interventional Medical Devices Optimizes Development and Quality Assurance

With the new horizontal testing system for catheters from ZwickRoell, manufacturers and development departments of interventional medical devices have a powerful tool for optimizing their testing processes: The modular platform enables realistic tests under clinic-like conditions. And it meets international standards (including ISO 10555, DIN EN ISO 25539, ASTM F623) – a decisive advantage for companies that rely on quality, efficiency and regulatory safety.

Application and advantages of the new catheter testing system

To ensure patient safety, interventional medical devices such as catheters, guidewires or insertion systems for heart valve implants must be tested under realistic conditions. Thanks to the horizontal testing system, clinical use can be simulated by combined feed and rotational movements, such as the performance characteristics of trackability, crossability, withdrawability, and pushability.

Advantages: Manufacturers receive reliable, reproducible test results that shorten development cycles, accelerate validation, and simplify regulatory documentation – all of which translate into clear competitive advantages in a dynamic market environment.

Modularity and ergonomics for maximum efficiency in laboratory operations

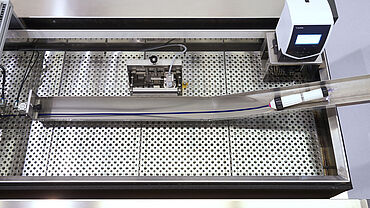

- The test platform offers flexible testing conditions – whether in a salt-resistant media bath, with individual anatomical models, or in a fluid-flowing hose system.

- The height-adjustable test bench enables ergonomic work and quick setup.

- System-controlled processes minimize operator errors and increase process reliability.

- And due to its modular architecture, the system can be easily expanded – for example, with additional sensors, actuators or custom requirements. This allows the testing solution to grow with a company’s needs and remain usable over the long term.

- Precise specimen feeding enables the exact implementation of cyclic test requirements within anatomical models or individual test arrangements.

- Even with long specimen, the feed and holding mechanism ensures high-precision test results and reliable data collection by eliminating the forces caused by friction and gravity.

- Submersible grippers with integrated catheter centering and individually adjustable gripping force also ensure particularly precise handling and exact positioning of specimens – even under demanding test conditions.

Compliant, audit-ready, and regulatory robust

The horizontal catheter testing system meets all relevant international standards (ISO 10555, DIN EN ISO 25539, ASTM F623, and others) and can be customized to meet specific customer requirements.

The time-synchronous video recording – above and below water – as well as the direct display of results in the testXpert test software enable transparent documentation and also allow a look back into the details of complex questions in the anatomy model and regulatory approvals.

The holding/feed unit neutralizes frictional and weight influences of the test specimen and ensures pure force measurement data – a decisive factor for the validation of complex product designs.

Economic efficiency and investment security

In addition to its technical performance, the system is also economically convincing:

- The salt-resistant materials guarantee durability, the lightweight pegboard system with numbered rows and columns enables reproducible setups, quick cleaning and reduced downtime.

- The high availability of the system increases productivity in the laboratory and reduces operating costs in the long term.

The horizontal test system is more than a materials testing machine – it is a strategic tool for research and development, quality assurance, innovation promotion and efficiency enhancement. It combines technical intelligence, clinical relevance and economic scalability in a compact system.

Erik Berndt - Global Industry Manager Medical & Pharma at ZwickRoell

We will be happy to answer any questions you may have!