Control Cube servo controller

Download- 19 bit

- 0.4 kHz

- 4 kHz

- Ideal for servohydraulic testing systems (single axis/multi axis/torsion)

Fatigue and fatigue strength testing with maximum flexibility and efficiency

For fatigue and durability tests, the use of servohydraulic testing systems is preferred. The performance of these systems is determined to a large degree by the measurement and control electronics used, together with the associated testing software. ZwickRoell offers the servo controller Control Cube and the testing software Cubus for this purpose. They are ideally suited for new testing systems, for retrofitting existing servo-hydraulic testing systems and for multi-axis applications.

This system was developed by ZwickRoell in collaboration with CaTs3 (Consultants in Automated Test & Structural-dynamic Simulation Systems). The latter's long-standing experience and expertise is reflected in a highly effective and powerful product well able to cope with constantly increasing customer requirements while meeting ZwickRoell's high quality and safety standards.

During development, special attention was given to achieving a high degree of testing system flexibility and expandability.

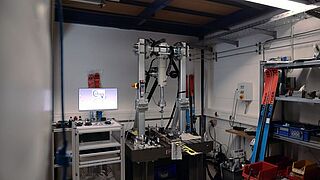

Our Cube servo controller in actions

Technical overview

- (1) PC connection via Ethernet interface

- (2) Multi-channel connection up to 32 control channels

- (3) Optional ± 10V set-value preset/monitor channels

- (4) Digital I/O connection

- (5) Remote-control connection

- (6) Hydraulic connection

- (7) System connection, e.g. for safety doors

- (8) Safety connection for integration of emergency-stop circuit

- (9) Channel identification via LED

- (10) Universal measurement amplifier for AC or DC sensors

- (11) Analog I/O module (option)

| Description | Value | |

| Control frequency | 4096 | Hz |

| Measured value acquisition (max. sampling rate) | 4096 | Hz |

| Expansion slots | 3 | |

| PC interface | Ethernet | |

| Universal measurement amplifier | 2x universal digital signal converter, can be increased to 8 per Control Cube; 19-bit resolution at 64 kHz oversampling and averaging | |

| Analog inputs and outputs | 2x analog ±10 V inputs, available for external commands or external measurement amplifiers 2x analog ±10 V outputs, available for synchronized control of external devices. Also available for monitor signals, e.g. for an external oscilloscope; optionally expandable. | |

| Digital inputs and outputs | 2x optically coupled digital inputs 2x digital outputs; optionally expandable. | |

| Electrical supply | 85 ... 264 V AC, 47 ... 63 Hz, 150 W | |

| Dimensions (H x W x D), approx. | 94 x 233 x 315 | mm |

| Weight, approx. | 8 | kg |