Spring Testing & Spring Testing Machines

Spring testing machines, also known as spring testing devices or spring test machines are used to test the quality performance of springs and ensure that they meet the specified requirements.

Springs are important construction elements in mechanical engineering, automotive engineering and numerous everyday applications and are used for energy storage and energy conversion, where the elastic properties of the materials are used. Depending on their design and mode of action, they fulfill specific functions—from damping and force storage to precise motion control.

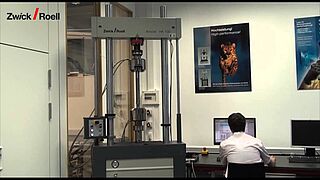

ZwickRoell performs spring tests primarily on coil springs, pneumatic springs, disc springs and gas springs. Our spring testing machines are therefore available in various designs and sizes to test different types of springs.

Coil springs - multi-channel Coil springs - uniaxial Pneumatic springs Disc springs Wave springs Gas springs Testing systems Request a consultation

Where are springs used?

Springs are used to store and convert energy, utilizing the elastic properties of materials.

The most important functions of springs are to:

- Absorb shocks and vibrations

Applications: suspension springs, shock absorbers, trailer couplings - Distribute and balance forces

Applications: mattresses, furniture, couplings, earthquake safety - Maintain the preload

Applications: preload roller bearings, chain and belt tensioners, clamps - Measure and control forces and torques

Applications: control valves, overload protection, torque wrench

Spring testing machine for multi-channel spring testing

Coil springs are cylindrically or conically wound wire springs that are subjected to compression. They store mechanical energy by deforming elastically when force is applied. Coil springs are key elements of modern suspension systems. They serve to dampen uneven road surfaces, contribute to driving safety and traction and enable comfortable handling. Their compact design and the possibility of combining them with shock absorbers make them the preferred solution in many vehicle models.

ZwickRoell offers a globally unique multi-channel spring testing machine for precise, standard-compliant and safe testing of coil springs, which works with up to nine load cells and can therefore determine the force-action curve of coil springs. Spring testing is important to avoid cracking or uneven spring characteristics. Only tested coil springs guarantee a long service life and reliable function.

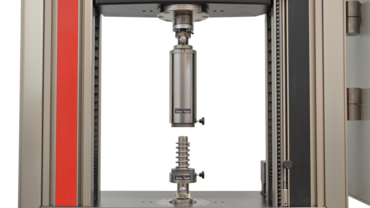

Uniaxial spring testing machine for helical compression springs

Rapid technical advance has led to a significant increase in the demands placed on the accuracy and durability of springs. The corollary of this is greater demands on manufacturing accuracy due to ever-smaller dimensional, form, and positional tolerances, with similarly enhanced requirements for testing technology.

Fatigue test on springs

Fatigue tests on springs can be carried out with a 100 kN HA series servo-hydraulic testing machine. Different frequencies can be specified.

Spring testing on pneumatic springs to EN 13597

Pneumatic springs are special springs that use compressed air instead of mechanical metal springs. The air pressure creates a springy effect. They are mainly used in vehicles and machines where a particularly comfortable, adjustable or vibration-damping suspension is required. For example, the suspension of trucks or buses can be adapted to different loads. Pneumatic springs are also used in trains and wagons.

In addition to the conventional tensile and compression tests, the following tests are also carried out in accordance with the EN 13597 standard:

- Testing air tight properties

- Internal pressure via static axial force

- Axial stiffness

- Radial stiffness

- Axial isobar property

Spring testing machine for pneumatic springs

The rubber and fabric composites used must be airtight, tear-resistant and weatherproof. The spring testing machine from ZwickRoell supports the quality assurance and development of pneumatic springs. It consists of a 250 kN universal testing machine, which is additionally equipped with a 50 kN horizontal electromechanical drive and a force measuring platform with five load cells (3x vertical, 2x horizontal).

The axial and horizontal stiffness characteristics of pneumatic springs are determined under vertical, horizontal or combined loading, and the following channels can be individually controlled:

- Force and travel, vertical

- Force and travel, horizontal

- Air or liquid internal pressure

For easy insertion of the specimen, the spring testing machine is equipped with a loading table that can be used to push the specimens into the spring testing machine.

Spring test on disc springs

Disc springs are conically shaped annular washers that exhibit elastic deformation under axial load. They are characterized by high spring forces with low space requirements and can be combined to form spring assemblies. Disc springs are mainly used in clutch systems, bearing preloads or safety valves.

Disc springs are tested under static load as well as under dynamic load. Static compression tests, for example, are carried out using a 400 kN electromechanical testing machine. The required characteristic values are determined using a pressure device for disk springs.

Dynamic fatigue tests are carried out with an HB servo-hydraulic load frame. Entire spring assemblies can also be tested for their service life. Crack tests and fatigue strength tests are necessary to prevent failures under dynamic load.

Spring test on wave springs

A single-layer wave spring is a circular flat wire with waves. Wave springs have a relatively low working height and can therefore be used in a very space-saving manner. Depending on the application, they are produced with shafts of different sizes and are therefore suitable for low to high axial loads.

The spring testing system for wave springs is used to carry out compression tests with an electromechanical servo test cylinder. The wave springs are inserted into the spring testing system on a carrier and tested.

Compression tests on wave springs can also be carried out with automation. A conveyor belt transports the wave springs to the electromechanical servo test cylinder. A good/bad sorting process can be carried out after the test.

Spring testing machine for gas springs

Gas springs, or gas struts, consist of a cylinder filled with gas (usually nitrogen) with an integrated piston. They generate a controlled, linear force effect that works particularly evenly and quietly. Gas springs can be used in a wide range of applications: they are used for trunk lids, engine hoods, height-adjustable chairs and tables, machine covers or in the medical sector.

As the internal pressure of gas springs is very high, cylinders, seals and piston rods must be tested for leaks, material strength and corrosion resistance. Material defects can lead to loss of function or safety risks.

The AllroundLine spring testing machine is designed to determine the insertion speed and the extension speed. The fast drives of the testing machine guarantee an application-related testing speed that corresponds to the area of application of the springs.

The use of several load cells in one testing machine enables the simultaneous testing of several gas springs. Switching between different gas spring types is also quick and easy. Simply call up a different test specification, which already contains all the default settings for the testing machine.