A Green Footprint for Your Testing Lab – Modernization of Testing Machines Reduces CO2 Emissions

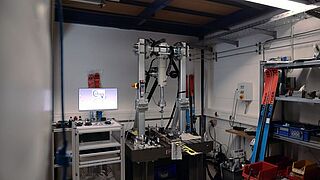

Sustainability combines environmental protection and durability. Modernizing your testing machine addresses both of these topics by refurbishing and reusing the robust steel and aluminum test frame. This not only saves money, but also tons of CO2.

The benefits are twofold: by modernizing your testing machine, you not only make an active contribution to saving CO2, but also receive a testing machine that is state of the art.

Sustainability and testing machines – what is the connection?

The testing machines are very robust and mainly consist of steel and aluminum. Depending on the size of the testing machine, different amounts of CO2 are generated during the production of these quantities. For example, the test frame of a 100 kN universal testing machine consists of approximately 300 kg steel and just under 100 kg aluminum. The production of these quantities generates around 2.2 tons of CO2—a tremendous burden on our environment. With our modernization solutions these CO2 emissions can be eliminated, since the test frame is reused. This means that you are not only actively contributing to climate protection, but you are also obtaining a testing machine in state-of-the-art condition—providing you with many benefits.

See our innovative product for yourself and benefit twice over—for you and your environment!

Potential emissions savings

| Modernized load frame | Aluminum component, approx. | Steel component, approx. | Total CO2 savings |

| zwickiLine | 20 kg | 40 kg | 0.4 tons |

| Table-top testing machine up to 30 kN | 30 kg | 100 kg | 0.7 tons |

| Table-top testing machine 50 to 100 kN | 100 kg | 310 kg | 2.2 tons |

| Floor-standing testing machine >100 kN | 100 kg | 1,360 kg | 4.3 tons |

Customer reduction of CO2 emissions

Continue using the same test tools and specimen grips

Accessories such as specimen grips, test tools and extensometers can simply be re-used after a modernization. Therefore, even accessories provide an opportunity for significant reductions in CO2 emissions.