- 50 kN

- +200 to +1200°C

- Creep

- Stress relax

- HE

- CCG

- ISO 204

- ASTM E139

- EN 2002-005

- ASTM F519

- ASTM E1457

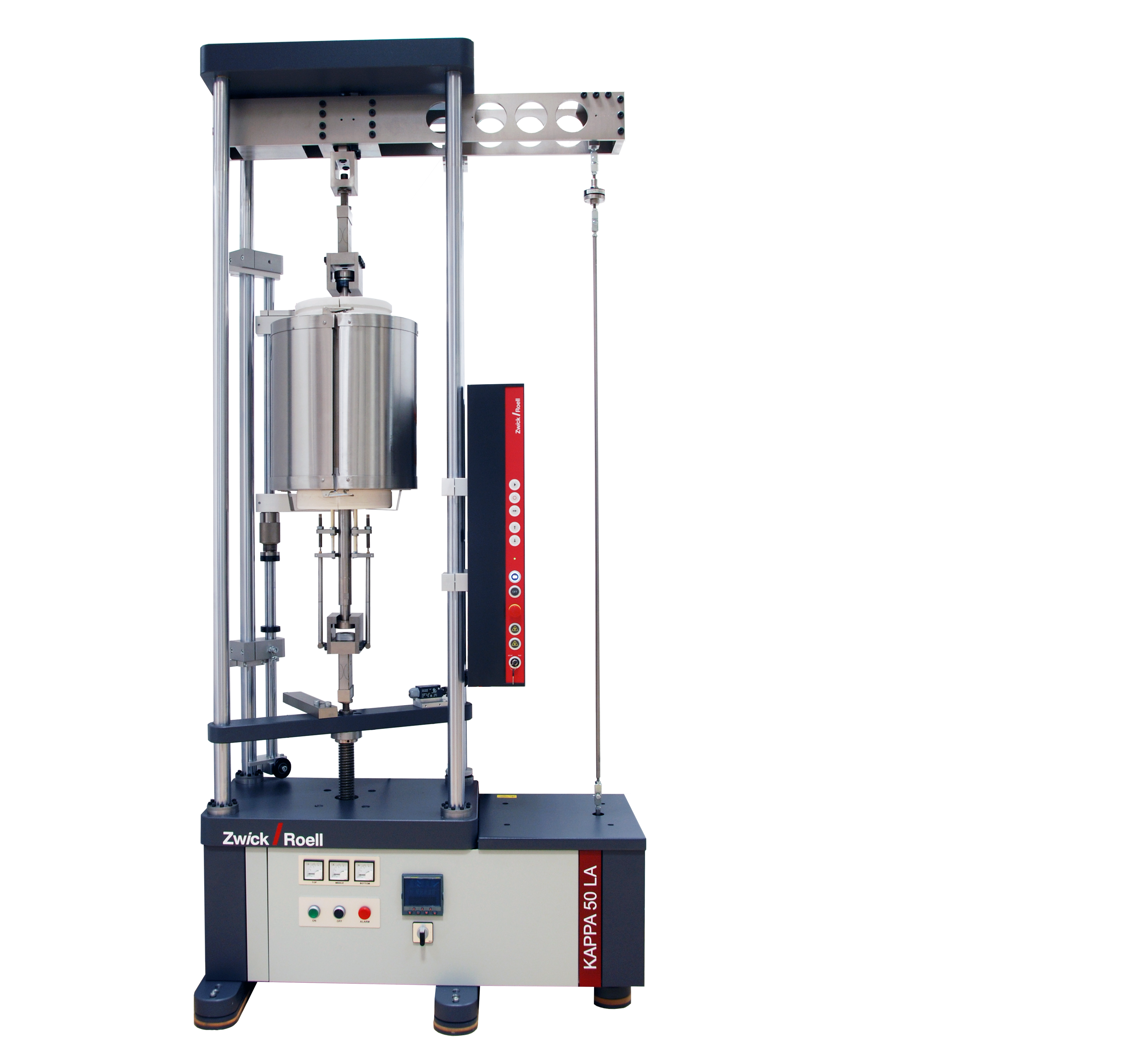

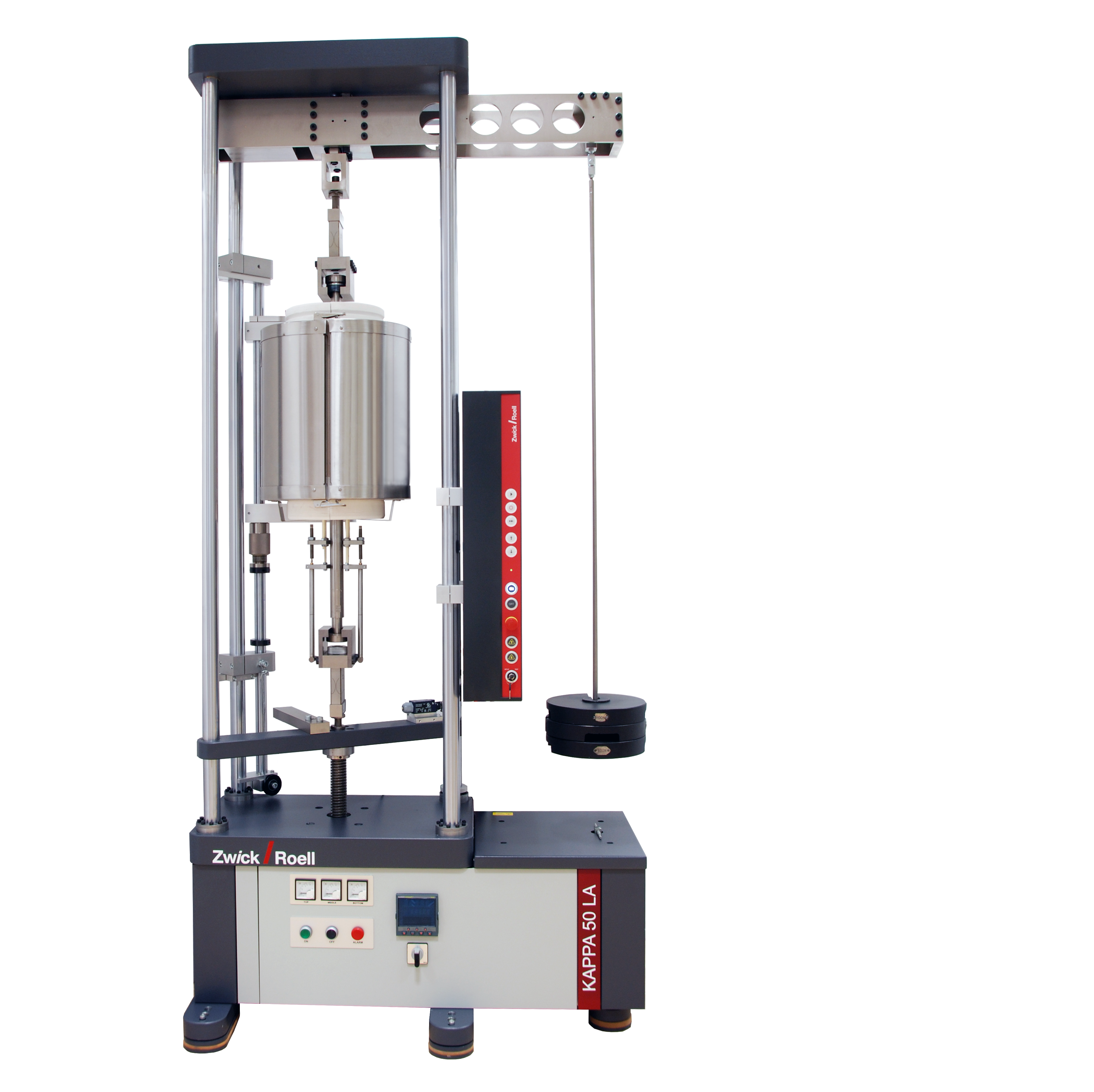

Lever arm creep testing machines

The Lever arm creep testing machines (Kappa LA) from ZwickRoell were developed for conventional fatigue and creep tests, capable of long test durations of up to 100,000 hours. The force is applied via either a prestressed spring or dead weight, up to a maximum test force of 50 kN.

The lever arm testing machines are equipped with wear-free flexible joints. These guarantee optimal lever arm mounting (patented) and precise force application in a wide load range.

Technical overview

| Kappa LA Spring | Kappa LA-DW | |

|---|---|---|

|  | |

| Force levels |

|

|

| Type of load | Prestressed spring | Dead weight |

| load cells | ✓ | - |

| Control mode |

|

|

| Type of test |

|

|

| Temperature range | +200 to +1200°C | +200 to +1200°C |

| Accessories for an extended temperature range | ||

| High-temperature furnace | • | • |

| Test load Fmax | 50 | kN |

| Test area | ||

| Height | 1500 1 | mm |

| Width | 520 2 | mm |

| Crosshead travel | 150 | mm |

| Load frame | ||

| Dimensions | ||

| Height | 2374 | mm |

| Width | 1100 | mm |

| Depth | 730 | mm |

| Weight | ||

| With machine electronics, approx. | 600 | kg |

| Lever arm ratio | 20 : 1 | |

| Drive | ||

| Crosshead speed max. | 50 | mm/min |

| Deviation from the set drive speed, max. | ± 0.13 | % of vactual |

| Crosshead return speed, max. | 50 | mm/min |

| Power input specifications | ||

| Supply voltage | 230 | VAC |

| Power consumption (full load), approx. | 0.8 | kVA |

- Maximum distance from the moving crosshead to the height-adjustable crosshead or base crosshead, without any accessories

- Clearance between the lead screws

- Measured over an interval of at least 5 s or 10 mm travel

| Test load Fmax | 50 | kN |

| Test area | ||

| Height | 1500 1 | mm |

| Width | 520 2 | mm |

| Crosshead travel | 150 | mm |

| Load frame | ||

| Dimensions | ||

| Height | 2374 | mm |

| Width | 1129 | mm |

| Depth | 730 | mm |

| Weight | ||

| With machine electronics, approx. | 600 | kg |

| Lever arm ratio | 20 : 1 | |

| Drive | ||

| Crosshead speed max. | 50 | mm/min |

| Deviation from the set drive speed, max. | ± 0.13 | % of vactual |

| Crosshead return speed, max. | 50 | mm/min |

| Power input specifications | ||

| Supply voltage | 230 | VAC |

| Power consumption (full load), approx. | 0.8 | kVA |

- Maximum distance from the moving crosshead to the height-adjustable crosshead or base crosshead, without any accessories

- Clearance between the lead screws

- Measured over an interval of at least 5 s or 10 mm travel

High-temperature furnace for Kappa LA

Because many materials only reveal their actual long-term behavior at elevated temperatures, testing at high temperatures is essential. A high-temperature furnace ensures that the specimen can be heated evenly for many hours or even months, maintaining temperature stability and allowing for testing to standards.

The high-temperature furnace for Kappa LA lever arm testing machines offers the highest temperature accuracy and flexibility for creep tests:

- 1, 2, or 3 independently controllable heating zones ensure optimal, uniform temperature distribution – with no overshooting.

- Testing up to +1,200°C in air.

- Variable slot shapes for thermocouples, extensometers and load strings, allowing for maximum adaptability to different specimens and test arrangements.

- Perfect integration of optical and contact extensometers for precise elongation and displacement measurement.

- Retrofittable, making it ideal for later expansion of existing Kappa LA systems.

Contact extensometers

Contact extensometers for creep testing are available for tensile as well as compression and flexure tests. In addition to different accuracy classes and measurement ranges, extensometers for extended temperature ranges are also available. A distinction is made between side- and axial-attaching extensometers, which are suitable for special test types such as crack propagation testing. Depending on the specimen shape, different sensor arms are used.

Our engineers are happy to help you select the optimal system for your creep testing machine from our extensive portfolio of extensometers.