Flat crush resistance of corrugated paper (CM test) | ISO 7263

ISO 7263 describes a method to determine the flat crush resistance of corrugated paper, which is used to produce corrugated board. While ISO 7263-1 describes the test using an A-flute geometry (A-flute), ISO 7263-2 is used for flat shafts (B-flute).

Disadvantages of this method: Only the A and B flutes are tested. The behavior of other types of fluting must therefore be determined mathematically in order to obtain their crush resistance.

Specimen preparation for the CMT is quite complex and requires fluting in a laboratory fluter, subsequent adhesion to an adhesive strip and post-conditioning of the paper heated during fluting. The flexure load used in the S-test according to DIN 5014 is comparable to the load used on the fluting in the CMT. The values from the S-test correlate to the initial maximum force used in the CMT, meaning the S-test can be an alternative option to the CMT. The test is carried out on a paper strip, eliminating the need for time-consuming sample preparation.

A method for determining the flat crush strength of manufactured corrugated board is described in ISO 3035.

Test procedure & test tools Related materials testing machines Downloads Request a consultation

CMT to ISO 7263 with ZwickRoell

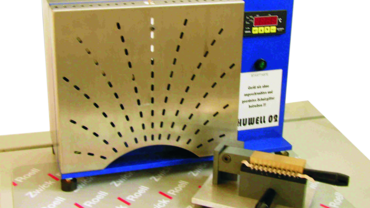

- CMT specimen production is time-consuming and requires a great deal of skill. The ZwickRoell fluter can quickly prepare specimens.

- One side of the formed corrugated paper is adhered to a backing strip and subjected to a compression test. The maximum load characterizes the behavior of multi-wall corrugated board during subsequent processing operations (punching, printing).

- When determining the flat crush resistance, it is important that force application to the specimen is exactly perpendicular during these tests. Precision-guided compression platens give the ZwickRoell CMT compression test kit extremely high lateral stiffness, thus ensuring reproducible determination of the characteristic values.

- The ZwickRoell CMT compression test kit is also suitable for the further testing of corrugated board in an edge crush test (ECT) to ISO 3037, a flat crush test (FCT) to ISO 3035 and a ring crush test (RCT) to ISO 12192 and TAPPI T822 on paper and cardboard and can be performed with our universal testing machines.