ASTM D6484 Open Hole Compression and ASTM D6742 Filled Hole Compression

The ASTM D6484 and ASTM D6742 standards describe the open hole compression (OHC) and filled hole compression (FHC) tests on composite materials.

The open hole compression (OHC) test to ASTM D6484 is used to determine the influence of a hole on the compressive strength of a laminate. The ratio of the OHC strength to compressive strength of the same unnotched laminate provides the OHC knockdown factor.

If a rivet or bolt is placed in the hole of the specimen, it is called filled hole compression (FHC) test, which is standardized in ASTM D6742. Similarly, comparing the FHC strength with the compressive strength of the same unnotched laminate provides the FHC knockdown factor.

The Boeing BSS 7260 (type I) and Airbus AITM1-0008 (specimen type B) also describe the standard test methods for open hole compression tests. Furthermore, the AITM1-0008 contains instructions for the filled hole compression (specimen type C) and plain compression (specimen type A) test.

Specimen and dimensions Running a test and test tools Testing machines Downloads Request a consultation

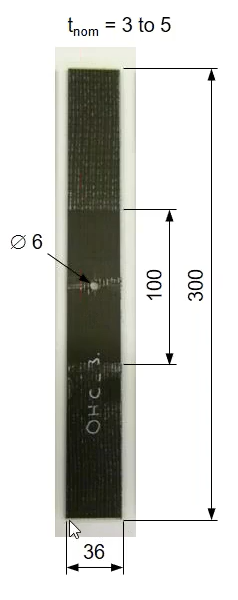

Specimens to ASTM D6484 and ASTM D6742

- Depending on the system of units used, the standard specimen for the open hole compression test to ASTM D6484 and the filled hole compression test to ASTM D6742 has a length of 300 mm (12 inches) and a width of 36 mm (1.5 inches) with a center hole of 6 mm (0.250 inches).

- The type I OHC specimen described in the Boeing industry standard BSS 7260 is also 12 inches long and 1.5 inches wide.

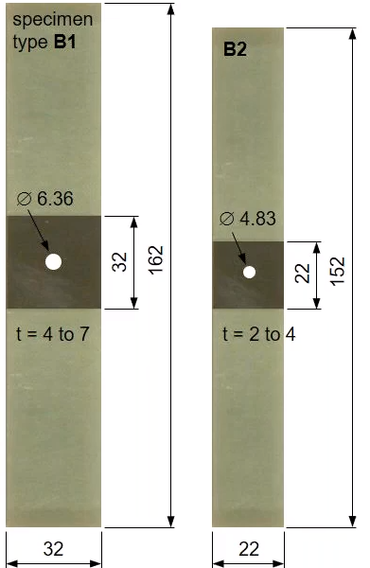

- The dimensions of the OHC specimen type B1 and B2 in the Airbus standard AITM 1-0008 are dependent on the thickness of the laminate and the load application method used in the compression test (shear loading or combined loading).

Running a test and test fixture

Open hole compression tests and filled hole compression tests are always performed with multidirectional laminates.

A strain measurement is not required, since strength is the deciding characteristic value to be determined. The only valid failure mode is compressive failure at the hole.

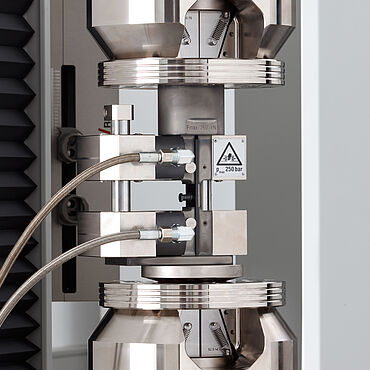

ASTM D6484, ASTM D6742 OHC / FHC compression test fixture

For ASTM D6484, ASTM D6742 and Boeing BSS 7260 type I the same specialized ASTM OHC / FHC compression test fixture with anti-buckling device is required. This keeps the relatively long OHC specimen from buckling.

- The force can be applied by means of shear loading and clamping of the test fixture in hydraulic grips, or by means of end loading and positioning of the test fixture between compression platens.

- The ASTM OHC / FHC compression test fixture can be used for compression forces up to 200 kN in a temperature range of -70 °C to 300 °C.

HCCF compression test fixture for Airbus AITM1-0008

The AITM1-0008 standard uses shorter specimens that can be clamped directly in guided specimen grips. The ZwickRoell HCCF compression test fixture is ideally suited for the performance of OHC and FHC tests according to Airbus AITM1-0008

- Due to the analogous specimen dimensions, compared to unnotched specimens type A1 and A2, OHC specimen dimensions B1 and B2 as well as FHC specimen dimensions C1 and C2 can be tested using the ZwickRoell hydraulic composites compression fixture (HCCF).

- The HCCF compression test fixture is ideal for compression forces up to 200 kN in a temperature range of -60 °C to 150 °C.

- The results are the compressive strength with an open or filled hole. A notch factor is also calculated, which indicates the loss of strength compared to a simple specimen without a hole.

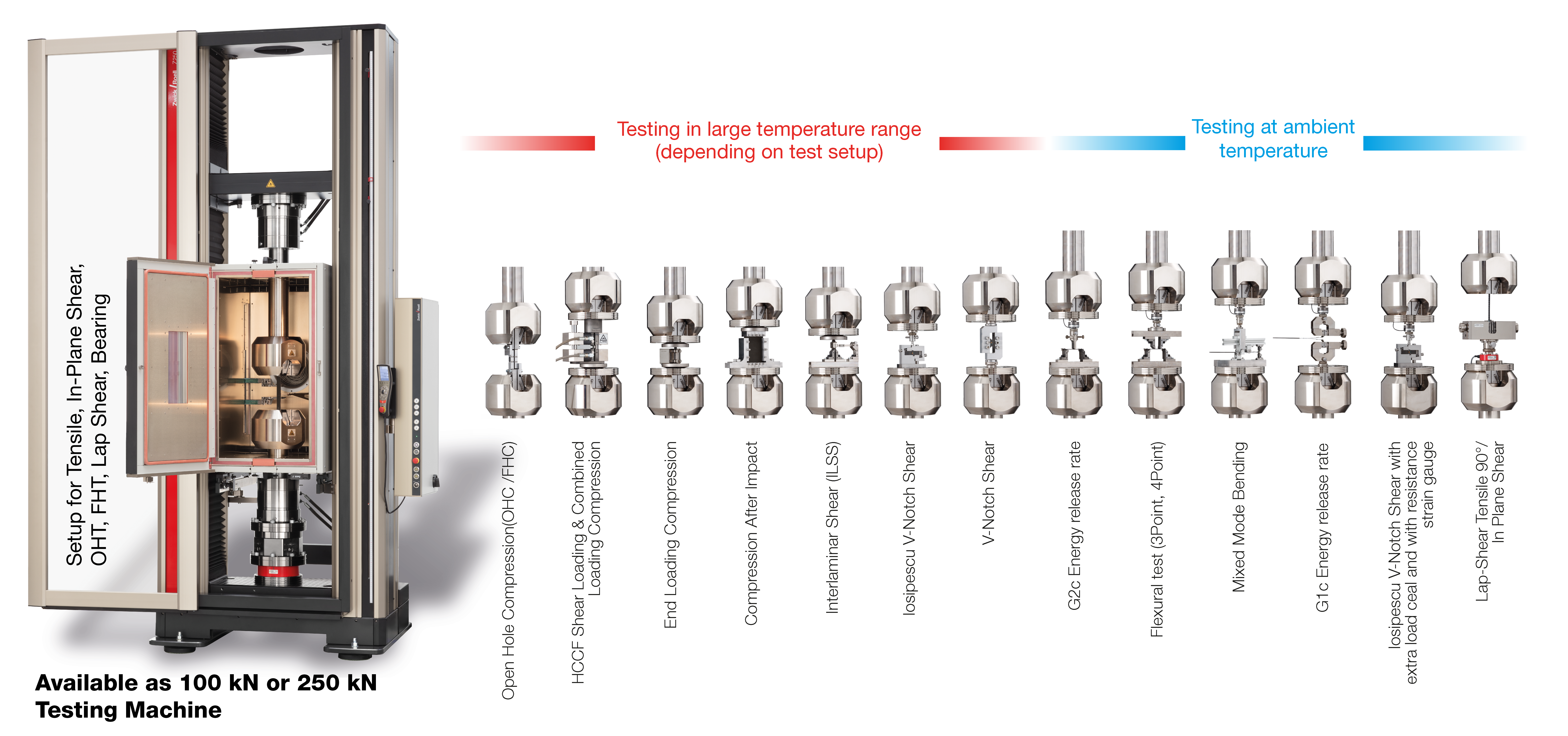

Modular testing system for composites

Larger testing laboratories with correspondingly high test volume use different testing machines for the very diverse composite testing methods, and can thereby minimize conversion efforts. The individual testing machines can be adjusted to the force range required for the various types of tests. If throughput rates are not high or consistent enough that an investment in multiple testing machines makes sense, an alternative option is to equip a single testing machine so that you can perform as many test methods as possible with the least amount of machine conversion effort.

ZwickRoell developed a modular design, which is available as a 100 kN or 250 kN testing machine covering 21 test methods and approximately 120 test standards (ISO, EN, ASTM, as well as Airbus AITM and Boeing BSS), and which allows for comprehensive characterization of fiber-reinforced composite materials at ambient temperature or for tests at low or high temperatures ranging from -80 °C to +360 °C.

Take advantage of the leading testing software in materials testing

ZwickRoell’s testXpert testing software offers:

- Simple operation: start testing right away and be a testXpert while maintaining maximum safety.

- Reliable and efficient testing: benefit from reliable test results and maximum testing efficiency.

- Flexible integration: testXpert is the optimal solution for all of your applications and processes—simply put, a more effective workflow.

- Future-proof design: testing software for the entire life cycle, ready for your future test tasks!