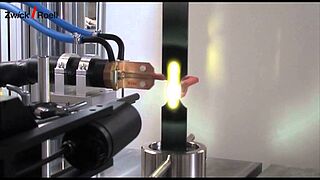

High-Speed Tensile Test

The fracture behavior of materials is dependent on, among other things, the loading rate. High-speed tensile tests provide characterization of the tensile properties of metals or plastics at high strain rates. These parameters are particularly valuable for crash simulations.

In a high-speed tensile test, testing is performed on flat dumbbell specimens with load application velocities of up to 20 m/s. The use of direct extension measurement on the specimen is also possible, allowing informative stress-strain diagrams to be generated.

High-speed tensile tests are performed using a high-speed testing machine. These servohydraulic testing machines achieve speeds of up to 20 m/s on specimens at forces up to 160 kN.

Applications Video Standards Measurement data acquisition Testing machines

Crash tests are already helpful in the design phase

It has long been known that mechanical-technological material properties depend (among other things) on the loading rate; in other words, the strain rate. In practice, however, it is impact loads that are frequently the cause of component failure. Designers engaged in developing crash-resistant automobiles quickly discovered that using material characteristic values obtained in quasi-static tests produced incorrect results. Only by using data from high-speed tensile tests was it possible to achieve a good level of correlation between numerical simulation and reality.

As numerical simulation is increasingly being used to design forming processes (sheet-metal forming, forging), knowledge of flow-curve dependency on forming rate is essential. In this context, discussion among materials scientists always centers on strain rates. Since these depend on the specimen shape lo, they are not suitable for specifying a machine characteristic. Machine manufacturers therefore state a piston speed.

Standards for High-Speed Tensile Tests

- SEP 1230: Determination of mechanical properties of sheet metal at high strain rates in high-speed tensile tests

- DIN EN ISO 26203-2: Metallic materials - Tensile testing at high strain rates - Part 2: Servohydraulic and other systems

- ISO/CD 22183 project: Plastics – Determination of tensile properties at high rate using a servohydraulic testing machine

- ISO 527-1, ISO 527-2; ASTM D638: Determination of tensile properties (covers only the area for low strain rates)

- SAE J2749 Nov 2008: High strain rate tensile testing of polymers

- ISO 18872: Plastics – Determination of tensile properties at high strain rates

- ISO 82568, ASTM D1822: Determination of tensile impact strength (plastics)

Test Data Acquisition

In high-speed tensile tests specimens are frequently fitted with strain gauges to obtain more accurate force measurement. Strain gauges are applied (on two sides, front and back) to an area of the specimen subject to elastic deformation only. The strain gages are arranged diagonally in a half-bridge configuration. The measurement signal exhibits considerably fewer signal oscillations than the force signal from the piezo load cell.

Strain gauges can also be applied to the specimen in the test cross-section for accurate strain measurement. In this case a strain gauge is used in a quarter-bridge. As test times are very short (only a few milliseconds), very fast measurement amplifiers are required, together with an additional transient memory card.