Industries

- Predominantly plastics

Max. energy

- 50 joules

Type of test

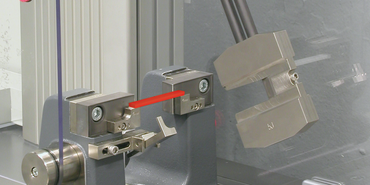

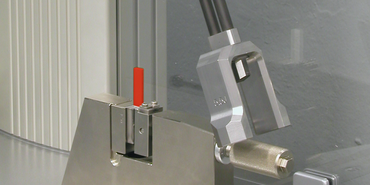

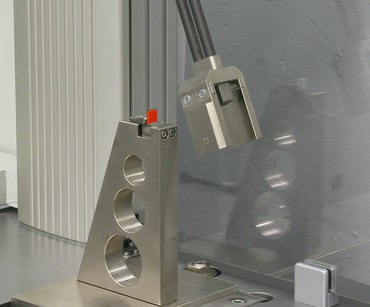

- Charpy

- Izod

- Dynstat

- Tensile impact test

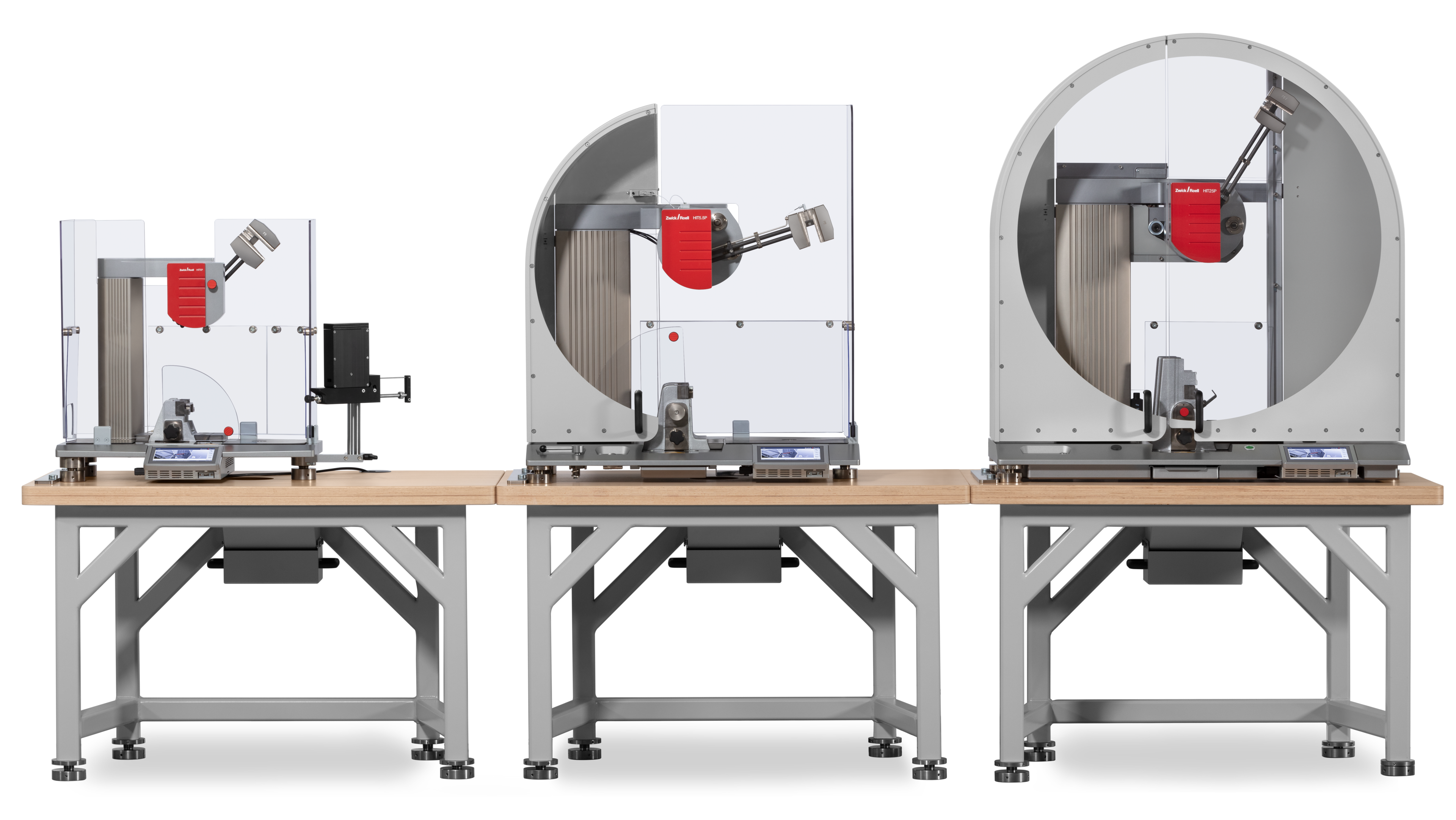

Pendulum impact testers for plastics testing – accurate, reliable and operator-friendly

In addition to tensile and flexure tests, Charpy impact tests are the most frequently performed mechanical tests in the polymer industry. ZwickRoell’s HIT series pendulum impact testers offer a high-precision, cost effective solution.

Pendulum impact test on plastics

Standard-compliant testing according to Charpy, Dynstat, and Izod and tensile impact tests, Method A/B with the HIT series of pendulum impact testers—be sure to hit your target with ZwickRoell!

Technical overview

| Type | HIT5P | |

| Item No. | 1064343 | |

| Use | with PC | |

| Rated initial potential energy | 5 (3.69 ft Ibf) | J |

| Dimensions | ||

| Total height, approx. | 684 | mm |

| Total width, approx. | 680 | mm |

| Total depth, approx. | 429 | mm |

| Weight | ||

| Without test tools, approx. | 70 | kg |

| With typical test tools, approx. | 75 | kg |

| Test results, numerical | Impact energy [%], impact energy [J], impact strength [kJ/m2] | |

| Units | SI, metric, Anglo-American | |

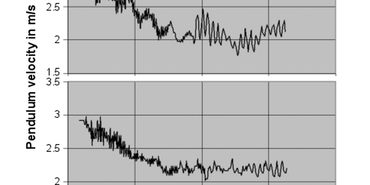

| Control functions | Friction and friction correction, vertical pendulum position, swing duration | |

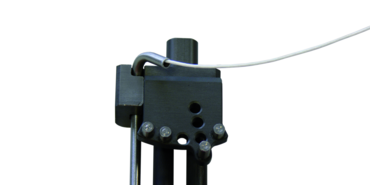

| Compensation functions | Air and bearing friction kinetic yoke energy (tensile impact test) | |

| Interfaces | •Ethernet port to connect a PC •2 x USB port to connect a printer or USB stick or USB Multiplexer •2x RS232 interface | |

| Pulse resolution | 0.018 | ° |

| Electrical connection | 100 ... 240, 50/60, 70 | V, Hz, W |

| Type | HIT 5.5P | |

| Item No. | 106434714.1100 | |

| Use | with PC | |

| Rated initial potential energy | 5.5 (4.06 ft Ibf) | J |

| Dimensions | ||

| Total height, approx. | 990 | mm |

| Total width, approx. | 870 | mm |

| Total depth, approx. | 573 | mm |

| Weight | ||

| Without tools, approx. | 136 | kg |

| With typical tools, approx. | 150 | kg |

| Test results, numerical | Impact energy [%], impact energy [J], impact strength [kJ/m2] | |

| Units | SI, metric, Anglo-American | |

| Control functions | Friction compensation, pendulum vertical position, swing duration, instrument data display | |

| Pulse resolution | 0.018 | ° |

| Interfaces | •Ethernet port to connect a PC •2 x USB port to connect a printer or USB stick or USB Multiplexer •2x RS232 interface | |

| Electrical connection | 100 ... 240, 50/60, 70 | V, Hz, W |

| Compressed air | 6, dry, oil-free (only required for compressed air-operated accessories) | bar |

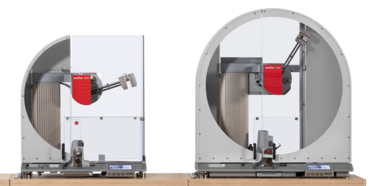

| Type | HIT25P | HIT25P with pendulum lifting | |

| Item No. | 1064351 | 1064349 | |

| Use | with PC | with PC | |

| Rated initial potential energy | 25 (18.45 ft Ibf) | 25 (18.45 ft Ibf) | J |

| Dimensions | |||

| Total height, approx. | 1162 | 1162 | mm |

| Total width, approx. | 1080 | 1080 | mm |

| Total depth, approx. | 583 | 658 | mm |

| Weight | |||

| Without test tools, approx. | 258 | 278 | kg |

| With typical test tools, approx. | 285 | 305 | kg |

| Test results, numerical | Impact energy [%], impact energy [J], impact strength [kJ/m2] | Impact energy [%], impact energy [J], impact strength [kJ/m2] | |

| Units | SI, metric, Anglo-American | SI, metric, Anglo-American | |

| Control functions | Friction compensation, pendulum vertical position, swing duration, instrument data display | Friction compensation, pendulum vertical position, swing duration, instrument data display | |

| Pulse resolution | 0.018 | 0.018 | ° |

| Safety device | Safety device left and right | Safety device, electrically interlocked | |

| Interfaces | •Ethernet port to connect a PC •2 x USB port to connect a printer or USB stick or USB Multiplexer •2x RS232 interface | ||

| Electrical connection | 100 ... 240, 50/60, 70 | 100 ... 240, 50/60, 150 | V, Hz, W |

| Type | HIT50P | HIT50P with pendulum lifting | |

| Item No. | 1064353 | 1064348 | |

| Use | with PC | with PC | |

| Rated initial potential energy | 50 (36.90 ft Ibf) | 50 (36.90 ft Ibf) | J |

| Dimensions | |||

| Total height, approx. | 1190 | 1190 | mm |

| Total width, approx. | 1080 | 1080 | mm |

| Total depth, approx. | 583 | 658 | mm |

| Weight | |||

| Without test tools, approx. | 2581 | 2781 | kg |

| With typical test tools, approx. | 2891 | 3091 | kg |

| Test results, numerical | Impact energy [%], impact energy [J], impact strength [kJ/m2] | Impact energy [%], impact energy [J], impact strength [kJ/m2] | |

| Units | SI, metric, Anglo-American | SI, metric, Anglo-American | |

| Control functions | Friction compensation, pendulum vertical position, swing duration, instrument data display | Friction compensation, pendulum vertical position, swing duration, instrument data display | |

| Pulse resolution | 0.018 | 0.018 | ° |

| Safety device | Safety device left and right | Safety device, electrically interlocked | |

| Interfaces | •Ethernet port to connect a PC •2 x USB port to connect a printer or USB stick or USB Multiplexer •2x RS232 interface | ||

| Electrical connection | 100 ... 240, 50/60, 70 | 100 ... 240, 50/60, 150 | V, Hz, W |

- The testing system has the weight required by the standard with a bolted down and approved table (HIT 50), or you can secure it to a concrete base weighing at least 200 kg with heavy-duty dowels/bolts.