Push and turn tests on screw caps

To ensure that containers filled with medicines cannot be opened by children in an uncontrolled manner, they are fitted with a childproof lock. The cap cannot be removed unless a combination of compressive and torsional loading is used.

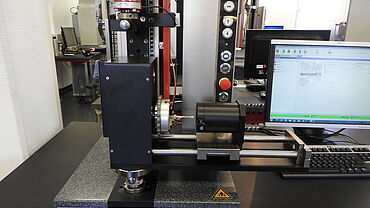

The torsion testing machine from ZwickRoell with a nominal force of up to 2.5 kN and a torsion drive (2 Nm or 5 Nm) is used for testing this particular function. The two test axes can be used for independent or combined axial/torsion tests as required. The containers are opened by an opening rotation, which is superimposed by an axial load. Important parameters in this test are the required opening torque and the functionality of the locking mechanism.

An automated testing system can also be used for larger specimen volumes. The roboTest L robotic testing system has a magazine for 30 containers, which are processed fully automatically. After the test, the medicine bottles are placed back in the magazine.

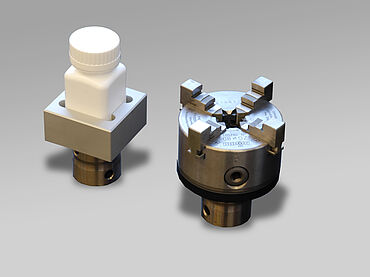

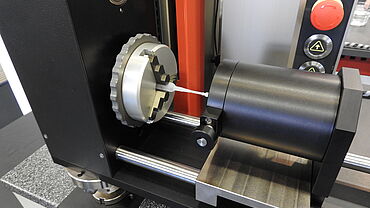

Test fixture for tip cap breakaway torque with a single-axis testing machine

Torque is applied to tip caps on disposable syringes to determine their breakaway torque. The syringe barrel is gripped firmly in a holding fixture. The tip cap is held in a positive-fitting fixture with toothed pulley and belt. The end of the tip cap is carried in a support bearing. To prevent transverse frictional forces, the holding fixture and support bearing are mounted on a common precision slide carriage. During the test the positive-fitting tip cap holder is turned 180° by testing machine travel. This ensures that the tip cap is fully twisted off.