Test methods

- Vickers

- Knoop

- Brinell

- Rockwell

- Carbon testing

- Ball indentation hardness

Test load

- 0.3 - 250 kg

- 3 - 3,000 kg

- Optionally from 0.01 kg

Versions

- Handwheel operated version

- Motorized Z-axis

- Fully automated component positioning

- Different test heights and load ranges

Standards

- ISO 6506

- ISO 6507

- ISO 4545

- ASTM E384

- ASTM E92

- ASTM E10

- ISO 6508

- ASTM E18

- DIN 51917

- ISO 2039-1

VisionLine micro and macro hardness testers at a glance

- The Vision hardness tester excels in a variety of test tasks, offering maximum efficiency for applications ranging from micro to macro hardness testing.

- Even in harsh industrial environments, the Vision works reliably and always complies with current standards.

- Thanks to the intuitive user guidance, the practical templates and the flexible operating panel, hardness testing is simple and ergonomic for every user. Precise hardness values can be determined for a wide range of materials and component shapes—from flat surfaces to tubes and balls, regardless of material types such as steel, copper or aluminum.

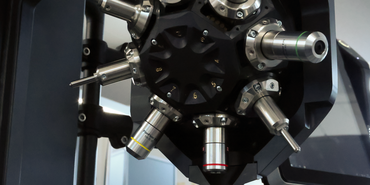

- The VisionLine's innovative tool changer with up to eight freely configurable positions enables rapid switching between different test methods, which increases the flexibility and efficiency of the instrument.

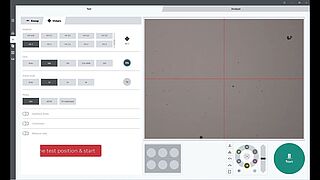

- The high-precision optical system ensures a clear representation of the hardness indentations. The software regulates the brightness, focus and evaluation of the indentations fully automatically. The AI-based algorithm delivers reliable results, even with challenging test surfaces.

Product advantages

- Load range 0.01 kg - 3,000 kg

- Ideal for Vickers, Knoop, Brinell, Rockwell, carbon and plastics testing

- Tests on clamped and unclamped components

- Automatic brightness control and AI-supported evaluation for maximum efficiency.

- Simple control via touch display, PC or the motion control operating panel

- Available in semi-automatic and fully automatic versions for component positioning

Video: Range of Applications of the Vision Universal Hardness Tester

Whether used for production purposes or in the lab

- With its various models, the Vision hardness tester covers a wide range of applications and is available as a handwheel version, with a motorized Z-axis or as a fully automatic hardness tester for extensive testing tasks.

- The new ecos™ III hardness testing software supports users from individual tests to complex testing tasks such as series testing, identical part testing, etc. and ensures simple, intuitive operation.

Hardness testing according to current standards

- Our VisionLine offers an extensive load range from 0.3 g - 250 kg or from 3-3,000 kg for the Vickers, Brinell, Rockwell, Knoop, plastics testing and carbon testing methods. All methods are covered by standards ISO 6506 / ASTM E10 , ISO 6507 / ASTM E384, ASTM E92, ISO 45452, ISO 6508 / ASTM E18, DIN 51917 and ISO 2039-1.

- With every method, you can expect a high level of result reliability thanks to the closed control loop and numerous sensors and test your specimens with the utmost precision.

- Automated test point evaluation and automatic brightness control make hardness testing more efficient and precise than ever before.

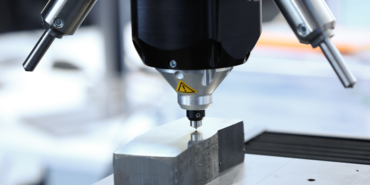

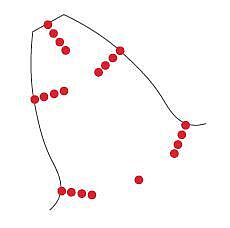

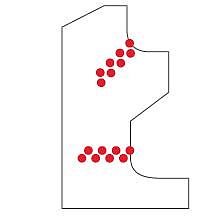

Testing the hardness of different materials and shapes

- Whether steel, aluminum, copper, brass, tin, gold, ceramic, carbon or plastic, our micro and macro hardness tester produces precise test results in any environment using the appropriate method.

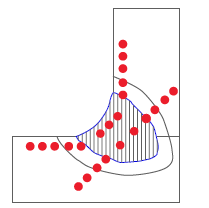

- The test specimens are either placed or clamped directly on the standard test anvil, on special prism, plane or spherical test anvils or other specimen fixtures. With the fully automated models, you can also use specimen grips for embedded specimens or matrices.

Hardness Testing Methods – Deep Insights with the Right Test Method

- Depending on the model, load ranges of 0.3-250 kg or 3-3,000 kg (optionally from 10 g) are covered.

- The macro hardness tester covers optical methods and differential-depth methods for your hardness testing applications. This includes Vickers, Brinell, Knoop or Rockwell.

- Different lenses are based on material hardness and test load and display your test results in high resolution. Your test results can be converted into other hardness values in accordance with industry standards.

VisionLine – Reliable Results and High Return on Capital

- Your investment in a Vision hardness tester significantly reduces the costs in your hardness testing processes. Fast and easy preparation of test tasks, the ability to store templates for recurring tests, and full automation of the test process reduce the operation time of hardness tests and save our customers time and money on a daily basis.

- The intuitive testing software not only enables quick familiarization and safe operation, but also works 65 % faster.

Vision variants in comparison

| Vision 250 | Vision 250-Z | Vision 250-Z Pro | Vision 3000 | Vision 3000-Z | Vision 3000-Z Pro | |

|  |  |  |  |  | |

| Load range | 0.3-250 kg | 0.3-250 kg | 0.3-250 kg | 3-3,000 kg | 3-3,000 kg | 3-3,000 kg |

| Tool changer | 3-fold Optional: 8-fold | 3-fold Optional: 8-fold | 3-fold Optional: 8-fold | 3-fold Optional: 8-fold | 3-fold Optional: 8-fold | 3-fold Optional: 8-fold |

| Display | 15.6" touch panel PC | 15.6" touch panel PC | Ext. PC | 15.6" touch panel PC | 15.6" touch panel PC | Ext. PC |

| Level of automation | Semi-automatic | Semi-automatic | Fully automatic | Semi-automatic | Semi-automatic | Fully automatic |

| Software | ecos™ III Touch | ecos™ III Touch | ecos™ III Pro | ecos™ III Touch | ecos™ III Touch | ecos™ III Pro |

| Positioning of component | Manual | Manual | Linear table | Manual | Manual | Linear table |

| Specimen feed | Handwheel | Motorized Z-axis | Motorized Z-axis and linear table | Handwheel | Motorized Z-axis and linear table | Motorized Z-axis and linear table |

| Load range | 0.3-250 kg (optionally from 10 g) |

| Max. speed, Z-axis | - |

| Dimensions (WxDxH) | 305x680x1271.5 (mm) |

| Weight | 240 kg |

| Operation | 15.6" touch panel PC |

| Max. test height | 220 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120/50 W |

| Test table (W x D) | Ø 90 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 0.3-250 kg (optionally from 10 g) |

| Max. speed, Z-axis | 25 mm/s |

| Dimensions (WxDxH) | 305x680x1166.5 (mm) |

| Weight | 260 kg |

| Operation | 15.6" touch panel PC |

| Max. test height | 175 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 720/100 W |

| Test table (W x D) | Ø 90 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

|

| Load range | 3-3,000 kg (optionally from 10 g) |

| Dimensions (WxDxH) | 360x837x1517.5 (mm) |

| Weight | 405 kg |

| Operation | 15.6" touch panel PC |

| Max. test height | 350 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120/50 W |

| Test table (W x D) | Ø 90 mm + 447x370mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 3-3,000 kg (optionally from 10 g) |

| Max. speed, Z-axis | 25 mm/s |

| Operation | 15.6" touch panel PC |

| Dimensions (WxDxH) | 360x837x1545 (mm) |

| Weight | 425 kg |

| Max. test height | 300 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 720/100 W |

| Test table (W x D) | Ø 90 mm + 447x370mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 3-3,000 kg (optionally from 10 g) |

| Max. speed, Z-axis | 25 mm/s |

| Operation | External PC with monitor, not included |

| Dimensions (WxDxH) | 850x837x1545 (mm) |

| Weight | 450 kg |

| Max. test height | 180 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 600/100 W |

| Test table (W x D) | 440 x 250 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 11 |

| Max. work piece weight | 50 kg |

| Protection class to EN 60529 | IP20 |

Accessories for Vision universal hardness tester

When looking at the hardness tester in detail, you will clearly see the many hidden benefits resulting from our many years of development. The Vision is now in its sixth generation and includes many improvements that are based on the feedback we received from our customers throughout the last several decades. Today, we continue using the latest technology on our machines to maintain our position as pioneer in the hardness tester market.