Specimen Preparation and Dimensional Measurement

A good test starts with a good specimen. ZwickRoell offers a number of solutions for materials testing, for specimen preparation, and for the measurement for plastics, metals or paper and cardboard.

Metal specimen preparation Plastic specimen preparation Paper and cardboard specimen preparation Specimen dimensioning

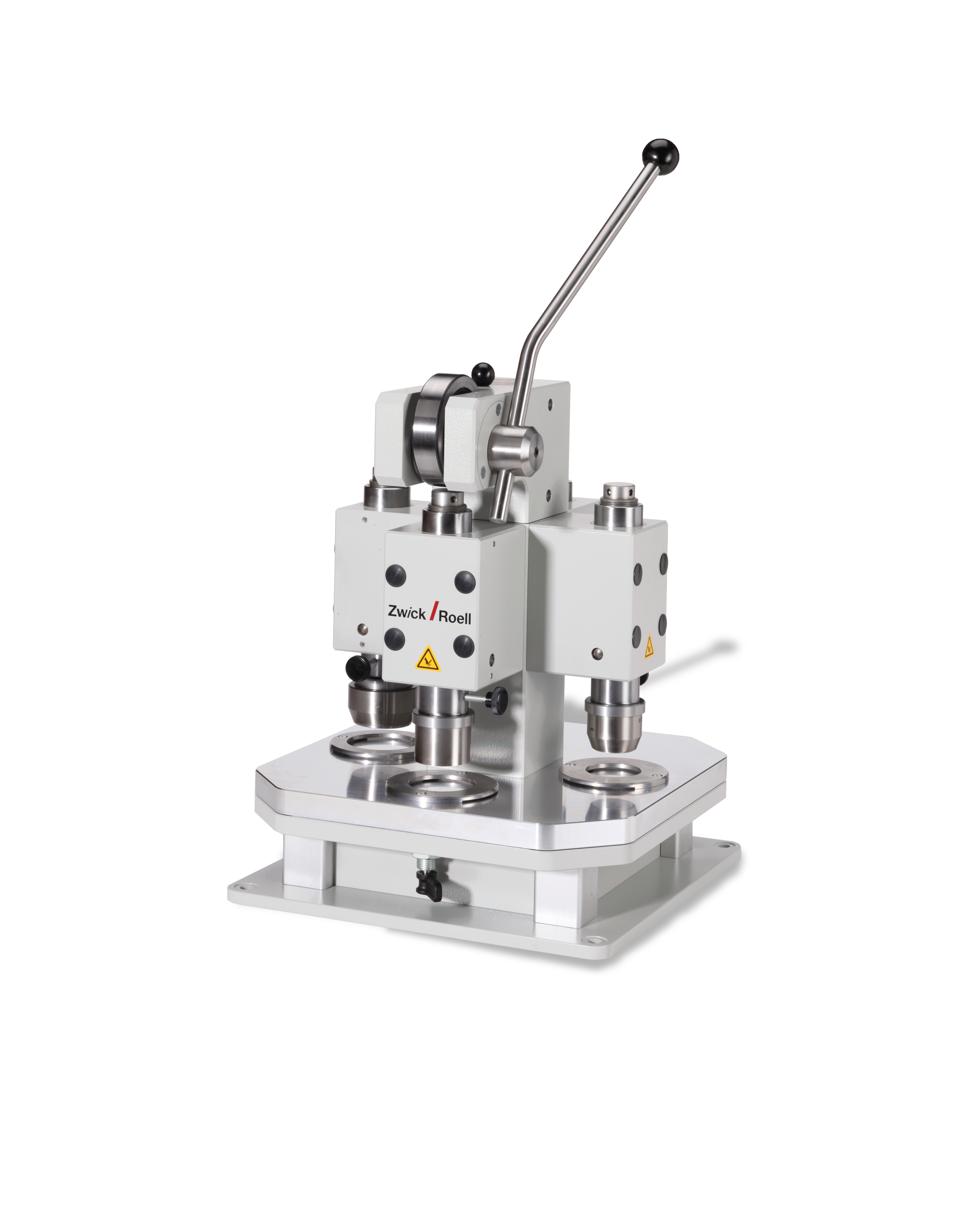

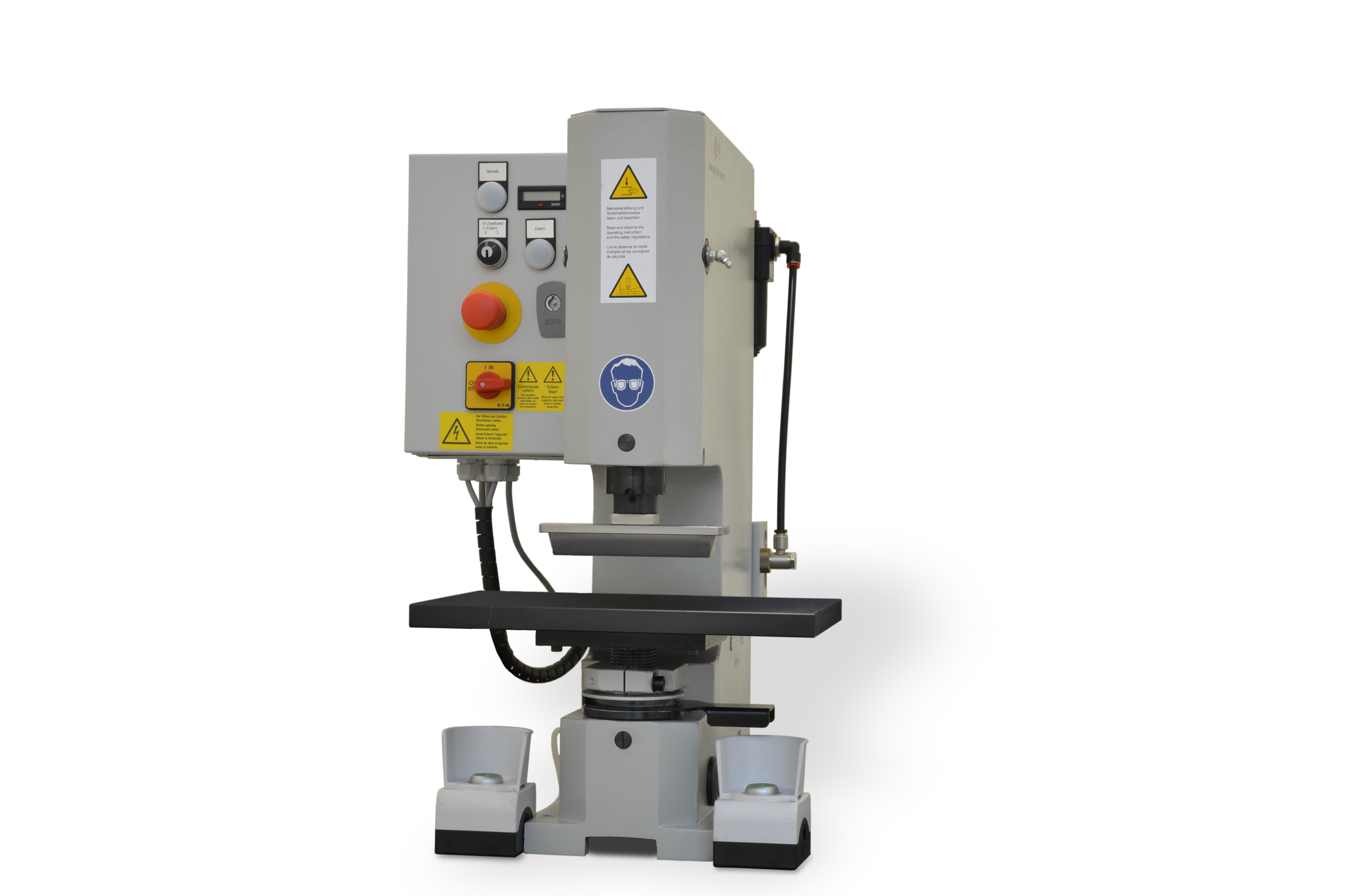

Metal specimen preparation or machining

Nowadays, specimens from sheet metal and metal foils are produced cost effectively and with accuracy using specimen blanking machines. Standards such as ISO 6892 and ASTM A370 specify that material changes due to strain hardening in the edge zone of the specimen may not influence the test results.

Numerous microstructural investigations on steel sheets have demonstrated that the strain-hardening zone along the cutting line is usually a maximum of 10% of the specimen thickness. This is achieved by a low cutting speed and special design of the blanking tools and offers considerable economic advantages in subsequent specimen grinding. This process ensures high quality of the specimen.

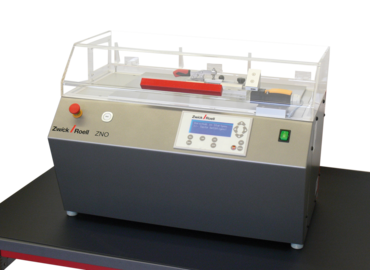

Plastic specimen preparation or machining

Standard thermoplastic and thermoset molding specimen are produced by injection or compression molding. Material characteristics are significantly influenced by production parameters such as pressure, temperature, and flow speed. Specimens are taken from slabs and components through mechanical processing such as per ISO 2818.

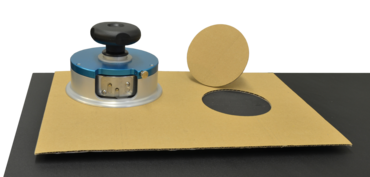

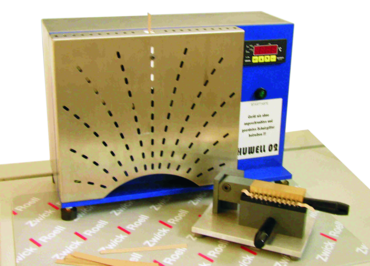

For specimen preparation on plastics, ZwickRoell offers the following devices:

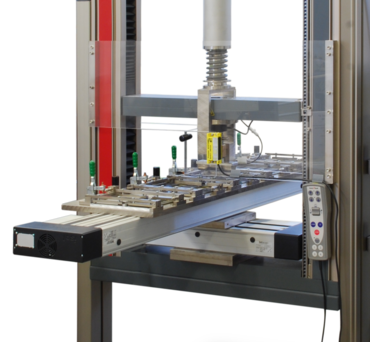

Cross-section measurement and thickness measurement

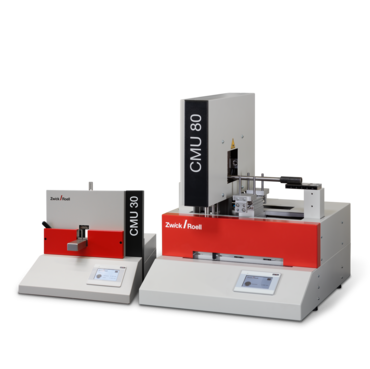

International standards for tensile tests or flexure tests place high demands on the specimen cross-section measurement.

Measuring errors can occur very quickly if the caliper is tilted or bent open. However, specimens with burrs or tapered specimen edges on flat specimens can also lead to incorrect manual measurements with a caliper.

High measurement accuracy also requires you to measure the thickness of particularly thin or unstable specimens.

Cross-section measuring devices and thickness measuring devices from ZwickRoell ensure accurate and reproducible determination of the specimen dimensions.