Environmental Chambers for Materials Testing

Environmental chambers for materials testing are systems used to control the environment in which a specimen is tested to simulate real-life application conditions.

Because the mechanical properties of many materials change based on the ambient in which they are used, it is important to understand the physical characteristics they exhibit in these environments as different forces are applied. This helps ensure the safety, optimization, and reliability of their end products.

ZwickRoell offers a variety of environment control options including temperature chambers, heating and cooling systems such as high-temperature furnaces, induction heating systems and vacuum chambers, which collectively cover a range of -80 °C to +360 °C and a high-temperature range up to +2,200 °C, and can be used for tests according to standards such as ISO 527-1 / ASTM D638, ISO 6892-2 / ASTM E8, ASTM E21, ASTM D412 and ISO 23529.

Specifically for medical applications, the 37°C climatic chamber and the temperature-controlled medium bath are the appropriate choice to enable tests at body temperature or to simulate physiological conditions in the body.

Temperature chambers -80 °C to +360 °C Heating systems for high-temperature testing up to +2,200 °C Climatic chambers for medical applications Request consultation

You may also be interested in:

Materials testing at cryogenic temperatures

Environmental test chambers -80 °C up to +360 °C

Every material behaves differently when subjected to temperature conditions. It is therefore important to run tests in different temperature ranges to determine the impact a specific temperature has on the properties of a material. For these tests, ZwickRoell offers various temperature and environmental test chambers that guarantee the perfect solution for every application.

- In a temperature range of -80 °C up to +360 °C, the temperature chamber for the AllroundLine testing machine is the perfect solution. Anywhere from tensile, compression and flexure tests on plastics, rubber, metals, elastomer or composites, tests can be easily performed at both temperature conditions or ambient temperature.

- The temperature chamber for the zwickiLine enables you to run tests in a temperature range between -50 °C and +180 °C. This temperature chamber is the cost-efficient option for small loads, with a small footprint.

| Temperature range | Load range | Applications | Can be retrofitted | Advantages | Extensometers | |

| Up to 250 kN |

| Yes |

| Flexible use of all

| |

| -50°C to +180°C | Up to 2.5 kN |

| Yes |

| Flexible use of different clip-on extensometers |

Climatic chambers for medical applications

- Testing under real conditions, i.e. body temperature conditions is of critical importance when it comes to medical products. To test stents, for example, ZwickRoell offers the 37 °C climatic chamber to simulate testing at body temperature.

- Fast reabsorbing materials, which are increasingly used in traumatology, surgery, and wound healing change their material properties incrementally as they make contact with mediums such saline solution. ZwickRoell’s temperature-controlled fluid bath provides the perfect solution to simulate these types of physiological conditions in the body.

| Temperature range | Applications | Range of application | Can be retrofitted | Advantages | |

|

|

| Yes |

| |

|

|

| Yes |

|

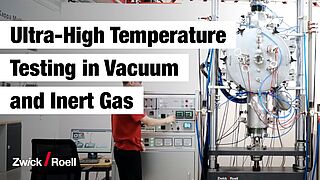

Heating systems for high-temperature testing from -80 °C up to +2,200 °C

Testing at different temperature levels and environmental conditions plays an important role in determining the temperature-dependent elastic behavior, strength and yield point of high-temperature resistant materials, including metals, ceramics, CMCs, graphite, etc. These high-temperature test are used primarily in the automotive, power generation and plant engineering sectors.

ZwickRoell features different heating systems for installation in our AllroundLine materials testing machines for tensile, compression, flexure and component tests, and in creep testing machines to perform tests in a temperature range of -80 °C up to +2,200 °C.

We offer the following modular heating systems:

- High-temperature furnace / single-furnace or two-furnace system

- Furnace carousel with 3, 4 and 6 furnaces

- Induction heating system

- Vacuum chamber

Detailed information can be found here:

Heating systems for creep testing High-temperature heating systems for tensile testing machines

Comparison of the high-temperature heating systems

| Temperature | Environment | Range of application | Applications | Advantages | |

|---|---|---|---|---|---|

High-temperature furnace |

|

|

|

|

|

| Induction heating system |

|

|

|

|

|

| Vacuum chamber |

|

|

|

|

|

Reliable test results, even under extreme temperatures

Frequently asked questions about environmental chambers

In materials testing, environmental test chambers are used in combination with a testing machine to simulate the temperature and climate of real-life application environments, while the machine applies a corresponding load. Testing materials under these conditions helps ensure the safety, optimization and reliability of the end product for which they are used.

The relative humidity is maintained in direct relation to the temperature—the higher the temperature, the more moisture the air can store. When the temperature changes, the relative humidity also changes. The humidity is therefore stabilized by regulating the temperature in the chamber.

Thermal cycling chambers, also known as thermocycling chambers, cycle through high and low temperatures to test a material specimen or component at these fluctuating temperatures. They differ from stability temperature chambers, in which the same temperature conditions are maintained over a specified period of time. The objective of cycling through different temperature extremes is to simulate the conditions to which materials are exposed in real-life applications. Materials commonly exposed to fluctuating temperature extremes include those used for manufacturing vehicles, medical devices, aircrafts, semi-conductors, bridges and more.

A thermal test chamber, also referred to as environmental chamber or climatic chamber, is a temperature regulated environment used in materials testing to simulate real-life environmental conditions while a specimen is subjected to tensile, compression or flexure testing with a materials testing machine. Environmental chambers work in direct relation with the testing machine and help material and component manufacturers, as well as researchers and quality control personnel determine the safety, quality and reliability of materials and products.