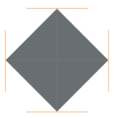

- Vickers

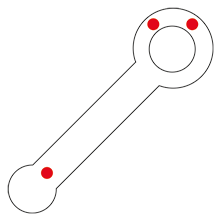

- Knoop

- Brinell

- Rockwell

- Carbon testing

- Plastics testing

- 0.3 - 250 kg

- 3 - 3,000 kg

- Handwheel operated version

- Motorized test unit

- Fully automatic test sequences

- Lite version without PC, display, clamping jaws or turret

- ISO 6506

- ISO 6507

- ISO 4545

- ASTM E384

- ASTM E92

- ASTM E10

- ISO 6508

- ASTM E18

- DIN 51917

- ISO 2039

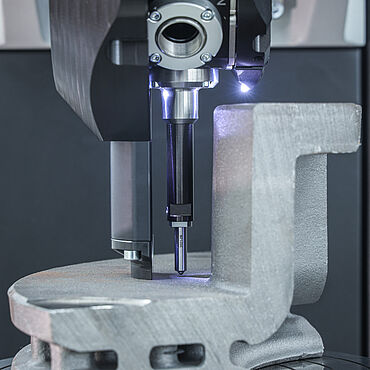

Overview of DuraVision macro hardness tester

- The DuraVision solves a wide variety of test tasks and is known for its efficiency in macro hardness testing applications.

- Even in harsh industrial environments, you can count on the reliable performance of this hardness tester, and always in accordance with currently applicable standards.

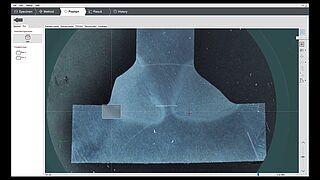

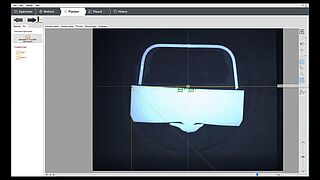

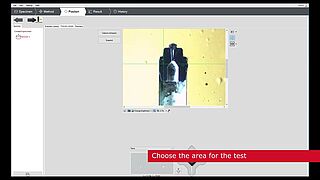

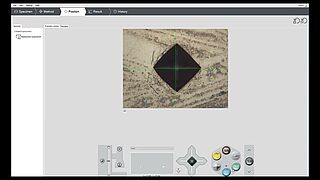

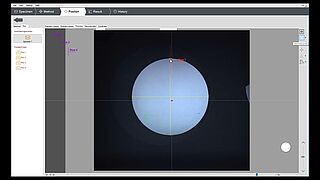

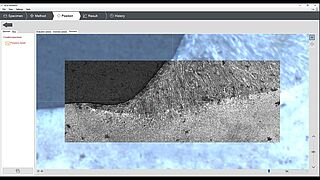

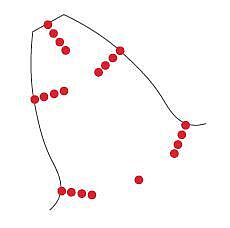

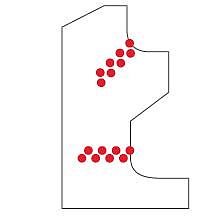

- The practical templates and comprehensive help features make macro hardness testing simple and easy to understand for any user. Precise hardness values are determined for different materials and component shapes. Test flat surfaces, tubes and pipes or spheres, whether made of steel, copper, aluminum or other materials.

Video: DuraVision macro hardness tester application range

Whether used for production purposes or in the lab

- With its different models, the DuraVision covers a wide range of applications and is suitable for extensive testing tasks in a handwheel operated version, with motorized nose cone infeed or as a fully automated hardness tester.

- The easy to use hardness testing software supports the operator with single tests, as well as complex test tasks.

Hardness testing according to current standards

- Our DuraVision series offers a wide load range from 0.3-250 kg or from 3-3,000 kg for test methods including Vickers, Brinell, Rockwell, Knoop, plastics testing and carbon testing. All methods are covered by the ISO 6506 / ASTM E10 , ISO 6507 / ASTM E384, ASTM E92, ISO 45452, ISO 6508 / ASTM E18, DIN 51917 and ISO 2039 standards.

- With every test method, you can expect high reliability of your test results and test your specimens with the highest level of precision.

- Automated test point evaluation and automatic brightness control make hardness testing more efficient and precise than ever before.

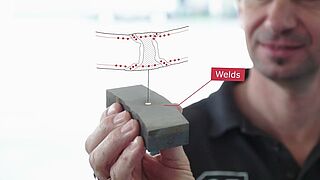

Testing the hardness of different materials and shapes

- Whether steel, aluminum, brass, zinc, gold, ceramics, carbon or plastic, with the right test method, our macro hardness tester produces accurate test results in any environment.

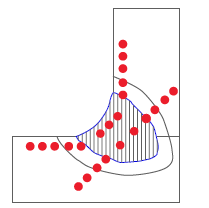

- The test specimens are either placed or clamped directly on the standard test anvil, on special prism, plane or spherical test anvils or other specimen fixtures. With the fully automated models, you can also use specimen grips for embedded specimens or matrices.

Hardness Testing Methods – Deep Insights with the Right Test Method

Depending on the model, the hardness tester covers load ranges from 0.3-250 kg or 3-3,000 kg.

The macro hardness tester covers optical methods and differential-depth methods for your hardness testing applications. This includes Vickers, Brinell, Knoop or Rockwell.

Different lenses are based on material hardness and test load and display your test results in high resolution. Your test results can be converted into other hardness values in accordance with industry standards.

DuraVision - reliable results & high return on investment

- Your investment in a DuraVision hardness tester significantly reduces the costs in your hardness testing processes. Fast and easy preparation of test tasks, the ability to store templates for recurring tests, and full automation of the test process reduce the operation time of hardness tests and save our customers time and money on a daily basis.

- With an intuitive testing software platform, familiarization with the program and reliable operation take no time at all.

DuraVision variants in comparison

| DuraVision 20/30 Lite | DuraVision 20/30 | DuraVision 200/300 | DuraVision 250/350 | |

|  |  |  | |

| Load range | 0.3-250 kg / 3-3,000 kg | 0.3-250 kg / 3-3,000 kg | 0.3-250 kg / 3-3,000 kg | 0.3-250 kg / 3-3,000 kg |

| Measuring turret | 2-way swivel turret | Star-shaped turret | Star-shaped turret | Star-shaped turret |

| Display | PC | Display | Display | PC |

| Level of automation | Semi-automatic | Semi-automatic | Semi-automatic | Fully automatic |

| Software | ecos Workflow Touch | ecos Workflow Touch | ecos Workflow Touch | ecos Workflow Pro |

| Positioning of component | Manual | Manual | Manual | Linear table |

| Specimen feed | Handwheel | Handwheel | Motorized test unit | Motorized test unit |

| Load range | 0.3 ... 250 kg |

| Max. speed, Z-axis | - |

| Dimensions (WxDxH) | 380 x 830 x 1400 (mm) |

| Weight | 420 kg |

| Operation | External PC, not included |

| Max. test height | 400 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120 W |

| Test table (W x D) | Ø 90 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 10/ 64 bit |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 3-3,000kg |

| Max. speed, Z-axis | - |

| Dimensions (WxDxH) | 380 x 830 x 1400 (mm) |

| Weight | 420 kg |

| Operation | External PC, not included |

| Max. test height | 400 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120 W |

| Test table (W x D) | Ø 90 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 10/ 64 bit |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 0.3 ... 250 kg |

| Max. speed, Z-axis | - |

| Dimensions (WxDxH) | 380 x 830 x 1400 (mm) |

| Weight | 420 kg |

| Operation | 10" touch display |

| Max. test height | 400 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120 W |

| Test table (W x D) | Ø 90 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 10/ 64 bit |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 3-3,000kg |

| Max. speed, Z-axis | - |

| Dimensions (WxDxH) | 380 x 830 x 1400 (mm) |

| Weight | 420 kg |

| Operation | 10" touch display |

| Max. test height | 400 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120 W |

| Test table (W x D) | Ø 90 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 10/ 64 bit |

| Max. work piece weight | 200 kg |

| Protection class to EN 60529 | IP20 |

|

| Load range | 3-3,000kg |

| Max. speed, Z-axis | 25 mm/s |

| Dimensions (WxDxH) | 380 x 830 x 1400 (mm) |

| Weight | 420 kg |

| Operation | 10" touch display |

| Max. test height | 500 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120 W |

| Test table (W x D) | Ø 90 mm + 447x370mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 10/ 64 bit |

| Max. work piece weight | 500 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 0.3 ... 250 kg |

| Max. speed, Z-axis | 25 mm/s |

| Positioning accuracy | ± 0.025 mm |

| Operation | External PC with monitor, not included |

| Dimensions (WxDxH) | 900 x 1050 x 1400 (mm) |

| Weight | 500 kg |

| Max. test height | 380 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120 W |

| Test table (W x D) | 440 x 250 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 10/ 64 bit |

| Max. work piece weight | 50 kg |

| Protection class to EN 60529 | IP20 |

| Load range | 3-3,000 kg |

| Max. speed, Z-axis | 25 mm/s |

| Positioning accuracy | ± 0.025 mm |

| Operation | External PC with monitor, not included |

| Dimensions (WxDxH) | 900 x 1050 x 1400 (mm) |

| Weight | 500 kg |

| Max. test height | 380 mm |

| Electrical connection | 110 ... 230 V (PH, N, PE) |

| Power frequency | 50/60 Hz |

| Power consumption | 120 W |

| Test table (W x D) | 440 x 250 mm |

| Evaluation camera resolution | 12 Mpix with CMOS sensor |

| Ambient temperature (to ISO/ASTM) | +5°C to +40°C |

| Humidity | Max. 70% (non condensing) |

| Operating system | Windows 10/ 64 bit |

| Max. work piece weight | 50 kg |

| Protection class to EN 60529 | IP20 |

Accessories for the DuraVision macro hardness tester

When looking at the hardness testing machine in detail, you will clearly see the many hidden benefits resulting from our many years of development. The DuraVision is now in its fifth generation and includes many improvements that are based on the feedback we received from our customers throughout the last several decades. Today, we continue using the latest technology on our machines to maintain our position as pioneer in the hardness tester market.